I did the fountain test with the injectors and glow plugs in. I could do the test again with them removed but as it does not stumble under a load I think I will just run it as long as I will need it for the summer and fall. If the low compression and smoking on startup are still occurring I will tear it down this winter, get the front cover off and check the timing marks. That will give me a baseline for moving forward. Thank you for your help. Larry.

B7100 Piston Installation

- Thread starter Schmotown

- Start date

Hi Larry,

as far as I understand is the smoke at startup the problem, after that the tractor is running fine and has power.

The smoke is either oil or Diesel that got into the exhaust unburnt. You mentioned poor starting. This is what I would focus on. The glow plugs you changed already but I would ask you to measure the current into each of them when pre glowing. I had a faulty glow plug and this lead to the same symptoms what you are seeing, a lot of smoke at startup and then running fine. Low compression could be the cause of that too of course.

Wrt to the injection pump, without the injectors no pressure is building up and all you see is a small drop of Diesel, which is basically all a cylinder gets per ignition.

Kind regards,

Hugo

as far as I understand is the smoke at startup the problem, after that the tractor is running fine and has power.

The smoke is either oil or Diesel that got into the exhaust unburnt. You mentioned poor starting. This is what I would focus on. The glow plugs you changed already but I would ask you to measure the current into each of them when pre glowing. I had a faulty glow plug and this lead to the same symptoms what you are seeing, a lot of smoke at startup and then running fine. Low compression could be the cause of that too of course.

Wrt to the injection pump, without the injectors no pressure is building up and all you see is a small drop of Diesel, which is basically all a cylinder gets per ignition.

Kind regards,

Hugo

torch

Well-known member

Equipment

B7100HSD, B2789, B2550, B4672, 48" cultivator, homemade FEL and Cab

Look on tractordata.com and scroll down to "Serial Numbers".I don't know the year but it is an "old" type.

torch

Well-known member

Equipment

B7100HSD, B2789, B2550, B4672, 48" cultivator, homemade FEL and Cab

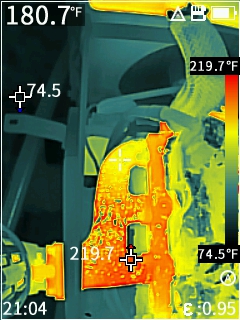

Just for fun and giggles, I investigated my B7100 (1994 version) exhaust manifold temperatures with a TIC. I set it to °F for consistency with your readings and turned on high, low and centre spot readings. After about 20 minutes of running:My questions:

1) Is 45F too big of a temperature difference between cylinders?

180°F at #1, 220°F at #3. 40°F difference. Ambient temp 75°F.

I don't think you have anything to worry about. Ok, it's sample size of two, but thus far 100% of all D750 engines investigated show notably lower EGT at the #1 cylinder. <lol>

Last edited:

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

The numbers your looking at are not rightMy tractor is a 1976. Thanks for the link!

They did not make an HST in 1976

@torch gave you the link for an B7100D

Your HST has to be 1980 or newer

TractorData.com Kubota B7100HST tractor information

Okay, looks like I have a 1983 tractor as my S/N is 12104. Thanks for the info!The numbers your looking at are not right

They did not make an HST in 1976

@torch gave you the link for an B7100D

Your HST has to be 1980 or newer

TractorData.com Kubota B7100HST tractor information

www.tractordata.com

torch

Well-known member

Equipment

B7100HSD, B2789, B2550, B4672, 48" cultivator, homemade FEL and Cab

Ooops. Sorry about that. I forgot they divvied up the B7100s that way. I was just thinking "older".The numbers your looking at are not right

They did not make an HST in 1976

@torch gave you the link for an B7100D

Your HST has to be 1980 or newer

TractorData.com Kubota B7100HST tractor information

www.tractordata.com

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

It happens to the best of us!Ooops. Sorry about that. I forgot they divvied up the B7100s that way. I was just thinking "older".

Hi Larry,

as far as I understand is the smoke at startup the problem, after that the tractor is running fine and has power.

The smoke is either oil or Diesel that got into the exhaust unburnt. You mentioned poor starting. This is what I would focus on. The glow plugs you changed already but I would ask you to measure the current into each of them when pre glowing. I had a faulty glow plug and this lead to the same symptoms what you are seeing, a lot of smoke at startup and then running fine. Low compression could be the cause of that too of course.

Wrt to the injection pump, without the injectors no pressure is building up and all you see is a small drop of Diesel, which is basically all a cylinder gets per ignition.

Kind regards,

Hugo

Hugo,Hugo, I'll measure the current on the glow plugs and report back. The low flow of diesel out of the injector pump makes sense to me now.

Thank you for your input.

Larry

The total amps for the glow plugs is 19A. I pulled all 3 glow plugs and powered them with jumper cables. They all glowed bright red and I think they're in great shape.

I have one more question (for today) about the low compression (300 psi) on all (3) cylinders of my rebuilt B7100:

I verified that cylinder #1 is at TDC of the compression stroke and did a leak down test again on that cylinder. At 100 psi inlet pressure my leak down gauge was reading about 8% loss. With the intake manifold removed I sprayed a soap solution through the #1 intake port and took a video (see below for link) of the bubbles coming from the back side of the valve while there was 100 psi in the cylinder. Does it make sense that there is this amount of leaking (bubbles) when there is only 8% leak down?

During this test I also taped a lightweight latex glove over the breather tube to check for blow-by and the glove did not inflate. Thanks for any comments. Larry.

I verified that cylinder #1 is at TDC of the compression stroke and did a leak down test again on that cylinder. At 100 psi inlet pressure my leak down gauge was reading about 8% loss. With the intake manifold removed I sprayed a soap solution through the #1 intake port and took a video (see below for link) of the bubbles coming from the back side of the valve while there was 100 psi in the cylinder. Does it make sense that there is this amount of leaking (bubbles) when there is only 8% leak down?

During this test I also taped a lightweight latex glove over the breather tube to check for blow-by and the glove did not inflate. Thanks for any comments. Larry.

torch

Well-known member

Equipment

B7100HSD, B2789, B2550, B4672, 48" cultivator, homemade FEL and Cab

They won't be if you keep doing that! They are supposed to be in series with the indicator, which drops the voltage. They are not designed or intended to be subjected to full battery voltage. Connecting them directly will burn them out sooner or later -- probably sooner.Hugo,

The total amps for the glow plugs is 19A. I pulled all 3 glow plugs and powered them with jumper cables. They all glowed bright red and I think they're in great shape.

torch

Well-known member

Equipment

B7100HSD, B2789, B2550, B4672, 48" cultivator, homemade FEL and Cab

8% isn't unacceptable, especially for a recently rebuilt cold engine. I assume you zeroed the gauge before starting the test?

It is certainly leaking past that valve. It is possible that lapping the valve might reduce the leakage. But bear in mind that the bubbles you are seeing are the result of a constant steady pressure. When running even at idle -- say 500 rpm -- that cylinder sees compression for about 3 tenths of a second at a time, so the volume of leakage per stroke is considerably less. I think this is a case of things looking worse in a static situation than they really are when viewed dynamically.

Similarly, rolling the engine over by hand seats the valves very gently without the normal velocity. It is possible that the valve can do better than that. Try doing the test again with the rocker cover off. With the cylinder pressurized put a piece of wood on the valve stem side of the rocker arm and give that a rap with a hammer to pop the valve open slightly and reseat it under pressure. See if that affects your percentages.

What happened with your compression readings when you installed the special valve core?

It is certainly leaking past that valve. It is possible that lapping the valve might reduce the leakage. But bear in mind that the bubbles you are seeing are the result of a constant steady pressure. When running even at idle -- say 500 rpm -- that cylinder sees compression for about 3 tenths of a second at a time, so the volume of leakage per stroke is considerably less. I think this is a case of things looking worse in a static situation than they really are when viewed dynamically.

Similarly, rolling the engine over by hand seats the valves very gently without the normal velocity. It is possible that the valve can do better than that. Try doing the test again with the rocker cover off. With the cylinder pressurized put a piece of wood on the valve stem side of the rocker arm and give that a rap with a hammer to pop the valve open slightly and reseat it under pressure. See if that affects your percentages.

What happened with your compression readings when you installed the special valve core?

Russell King

Well-known member

Lifetime Member

Equipment

L185F, Modern Ag Competitor 4’ shredder, Rhino tiller, rear dirt scoop

I'm going to restart this thread regarding my original postings about my B7100 as things have changed. When I first purchased this tractor it was hard to start and smoked for a couple of minutes after starting. Because of this I removed the head and pistons and measured the bores. In my previous posts I said that the bores were all in spec. and because of the good readings I replaced the pistons, rings, rod bearings and bought a fully loaded head from Kumar Bros. in an effort to remedy the problems. These changes made little difference. My compression tests went from 240 psi prior to repairs to 300 psi after the parts were replaced.

Because of these poor post-repair results I again removed the head and remeasured my cylinder bores and found that my original measurements were incorrect. The (3) cylinder bores read 2.800" at the top of the cylinders (.001 over spec) with the mid-point and bottom of the cylinders measurement only slightly better. I think this condition resulted in my low compression readings.

Yesterday I split the tractor again and removed the front gear cover to prepare the block to take to my Kubota Dealer to have new liners installed and bored but before I proceed any further I have a couple of questions.

I would like to check the timing with the front cover removed to double check that the low compression readings were not the result of the timing marks being misaligned. I think that if #1 cylinder was at TDC of the compression stroke with two pushrods in the lifters confirming that I am on the compression stroke then the timing marks on the gears would be lined up. Is my assumption correct?

If I do rotate the crank could I damage the bearings because there is no oil pressure?

Thanks in advance for your input.

Larry

Because of these poor post-repair results I again removed the head and remeasured my cylinder bores and found that my original measurements were incorrect. The (3) cylinder bores read 2.800" at the top of the cylinders (.001 over spec) with the mid-point and bottom of the cylinders measurement only slightly better. I think this condition resulted in my low compression readings.

Yesterday I split the tractor again and removed the front gear cover to prepare the block to take to my Kubota Dealer to have new liners installed and bored but before I proceed any further I have a couple of questions.

I would like to check the timing with the front cover removed to double check that the low compression readings were not the result of the timing marks being misaligned. I think that if #1 cylinder was at TDC of the compression stroke with two pushrods in the lifters confirming that I am on the compression stroke then the timing marks on the gears would be lined up. Is my assumption correct?

If I do rotate the crank could I damage the bearings because there is no oil pressure?

Thanks in advance for your input.

Larry

torch

Well-known member

Equipment

B7100HSD, B2789, B2550, B4672, 48" cultivator, homemade FEL and Cab

Did you ever recheck the compression with the correct Schrader valve core installed in the gauge?I'm going to restart this thread regarding my original postings about my B7100 as things have changed. When I first purchased this tractor it was hard to start and smoked for a couple of minutes after starting. Because of this I removed the head and pistons and measured the bores. In my previous posts I said that the bores were all in spec. and because of the good readings I replaced the pistons, rings, rod bearings and bought a fully loaded head from Kumar Bros. in an effort to remedy the problems. These changes made little difference. My compression tests went from 240 psi prior to repairs to 300 psi after the parts were replaced.

Because of these poor post-repair results I again removed the head and remeasured my cylinder bores and found that my original measurements were incorrect. The (3) cylinder bores read 2.800" at the top of the cylinders (.001 over spec) with the mid-point and bottom of the cylinders measurement only slightly better. I think this condition resulted in my low compression readings.

Yesterday I split the tractor again and removed the front gear cover to prepare the block to take to my Kubota Dealer to have new liners installed and bored but before I proceed any further I have a couple of questions.

I would like to check the timing with the front cover removed to double check that the low compression readings were not the result of the timing marks being misaligned. I think that if #1 cylinder was at TDC of the compression stroke with two pushrods in the lifters confirming that I am on the compression stroke then the timing marks on the gears would be lined up. Is my assumption correct?

If I do rotate the crank could I damage the bearings because there is no oil pressure?

Thanks in advance for your input.

Larry

As far as rotating the crank -- by hand -- after the engine has been running previously, there should be a nice film of oil on the bearings to protect them. After all, it's less force than spinning it with the starter motor each time you crank the engine, right? And no different than applying some oil to the bearings and journals when assembling in anticipation of cranking the engine over.

Torch,Did you ever recheck the compression with the correct Schrader valve core installed in the gauge?

As far as rotating the crank -- by hand -- after the engine has been running previously, there should be a nice film of oil on the bearings to protect them. After all, it's less force than spinning it with the starter motor each time you crank the engine, right? And no different than applying some oil to the bearings and journals when assembling in anticipation of cranking the engine over.

I did recheck the compression with the Schrader Valve you suggested and no difference.

Do you think my assumption about lining up the timing marks is correct?

Thanks, Larry.