Wolfman, thanks for the advice.

My next-door neighbour's B7100HST has such a block, but my elderly B7100D does not, and I'm not keen to cut into that steel line to fit one – though I suppose it would be more convenient to be able to raise and lower the 3-point hitch and use the FEL without having switch between the two. One would also have to be careful to ensure that the controls included a pressure relief valve. By the way, what is the design pressure of the existing system?

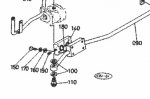

The advice given in the Kubota manual is to return the oil to the transmission case via the existing filler hole, which appears to be 1/2" BSP (or possibly NPT – they're both 14TPI, but as the connection is not under pressure it doesn't really matter). I'm considering making some sort of tee arrangement so the filler can still be used as a filler without any dismantling being required. What's your intention with the return line?

FELs often have only single-acting lift rams, relying on gravity to lower the bucket again. Double-acting rams do give the advantage that one can use the weight of the tractor, not just the loader, to make the bucket dig in a bit if required. One thing that occurs to me is that with using the existing hydraulic system, single-acting lift rams would make the oil level in the transmission case go up and down rather more than would double-acting rams. With the latter some oil goes back into the case from the other side of the piston (though less than is drawn from the case, since the spear takes up some of the volume of its end of the cylinder). A pair of 50mm (2") cylinders with 300mm (12") strokes would take about 1.2 litres to fill, and the transmission holds 11.5 litres. Fatter cylinders or longer strokes could possibly be a problem if only single-acting?

My next-door neighbour's B7100HST has such a block, but my elderly B7100D does not, and I'm not keen to cut into that steel line to fit one – though I suppose it would be more convenient to be able to raise and lower the 3-point hitch and use the FEL without having switch between the two. One would also have to be careful to ensure that the controls included a pressure relief valve. By the way, what is the design pressure of the existing system?

The advice given in the Kubota manual is to return the oil to the transmission case via the existing filler hole, which appears to be 1/2" BSP (or possibly NPT – they're both 14TPI, but as the connection is not under pressure it doesn't really matter). I'm considering making some sort of tee arrangement so the filler can still be used as a filler without any dismantling being required. What's your intention with the return line?

FELs often have only single-acting lift rams, relying on gravity to lower the bucket again. Double-acting rams do give the advantage that one can use the weight of the tractor, not just the loader, to make the bucket dig in a bit if required. One thing that occurs to me is that with using the existing hydraulic system, single-acting lift rams would make the oil level in the transmission case go up and down rather more than would double-acting rams. With the latter some oil goes back into the case from the other side of the piston (though less than is drawn from the case, since the spear takes up some of the volume of its end of the cylinder). A pair of 50mm (2") cylinders with 300mm (12") strokes would take about 1.2 litres to fill, and the transmission holds 11.5 litres. Fatter cylinders or longer strokes could possibly be a problem if only single-acting?