Early 80s L275DT Cold Start

- Thread starter forrest carver

- Start date

ve9aa

Well-known member

Equipment

TG1860, BX2380 -backblade, bx2830 snowblower, fel, weight box,pallet forks,etc

Knowing that I am not a diesel mechanic nor an expert, the next thing I myself would question is fuel quality or compression.

I realize diesel doesn't suddenly go bad, nor near as quickly as gasoline, but do you know how old it is?

2, 5, 10 yrs? (I might have missed this factoid)

(or--wild theory---your sister (or whomever) didn't dump gas into the fuel tank, right) ?

I'll reread this thread to see what you said about the fuel(and supply thereof, ie: flow out of the injector pump), bleeding air out the lines, etc. and edit this post out if I am way out in left field.

I realize diesel doesn't suddenly go bad, nor near as quickly as gasoline, but do you know how old it is?

2, 5, 10 yrs? (I might have missed this factoid)

(or--wild theory---your sister (or whomever) didn't dump gas into the fuel tank, right) ?

I'll reread this thread to see what you said about the fuel(and supply thereof, ie: flow out of the injector pump), bleeding air out the lines, etc. and edit this post out if I am way out in left field.

ve9aa

Well-known member

Equipment

TG1860, BX2380 -backblade, bx2830 snowblower, fel, weight box,pallet forks,etc

OK, I'll leave my previous post stand...

You said you "checked the fuel line".

Describe what you mean?

ie: saw diesel dribble from a filter when you popped a hose off?

or:

cracked an injector or injector line when you were cranking and saw fuel squiring out under pressure?

I am a little out of my league advising how to bleed lines and injectors so I won't make a fool out of myself by trying.

The lack of black smoke has me scratching my head (a little) thinking (for whatever reasons) that you are not getting enough fuel into the cylinders as you seem to now have 2 working GP's (maybe even 3) and you don't say anything about it cranking super slow, so I presume you have cranking working well.

I'll need to defer to the real experts here. I sense you're a lot closer now, but just not "quite there".

Compression and/or lack of sufficient fuel (blockage? air? gelled fuel? aliens?...ok, probably not aliens)

You said you "checked the fuel line".

Describe what you mean?

ie: saw diesel dribble from a filter when you popped a hose off?

or:

cracked an injector or injector line when you were cranking and saw fuel squiring out under pressure?

I am a little out of my league advising how to bleed lines and injectors so I won't make a fool out of myself by trying.

The lack of black smoke has me scratching my head (a little) thinking (for whatever reasons) that you are not getting enough fuel into the cylinders as you seem to now have 2 working GP's (maybe even 3) and you don't say anything about it cranking super slow, so I presume you have cranking working well.

I'll need to defer to the real experts here. I sense you're a lot closer now, but just not "quite there".

Compression and/or lack of sufficient fuel (blockage? air? gelled fuel? aliens?...ok, probably not aliens)

Before starting this project, I saw that the tank had a little diesel in it, so I added a fresh gallon or two. I still have 3-4 gallons available nearby.

Yesterday during my fuel line check I saw diesel dribbling from the hose where it connects to the engine from the fuel filter. I drained about a pint of diesel and there did appear to be evidence of some water in the fuel but I was hoping that draining it out would get rid of it.

At work I saw a friend and mechanic who owns a Kubota in passing and mentioned my issue, he suggested "cracking the injectors and bleeding some fuel" but didn't have time to elaborate.

I could head back there today but I'd really want to know what I was doing. Thanks to Russell King I have the manual on how to test the injectors, but really lacking the confidence to take a stab at it and not sure I have the tools. Could also drain all the fuel and start totally fresh, but I think the tank is mostly new fuel.

Regarding the compression test, that also appears to be quite an undertaking unless I'm misunderstanding the manual.

Yesterday during my fuel line check I saw diesel dribbling from the hose where it connects to the engine from the fuel filter. I drained about a pint of diesel and there did appear to be evidence of some water in the fuel but I was hoping that draining it out would get rid of it.

At work I saw a friend and mechanic who owns a Kubota in passing and mentioned my issue, he suggested "cracking the injectors and bleeding some fuel" but didn't have time to elaborate.

I could head back there today but I'd really want to know what I was doing. Thanks to Russell King I have the manual on how to test the injectors, but really lacking the confidence to take a stab at it and not sure I have the tools. Could also drain all the fuel and start totally fresh, but I think the tank is mostly new fuel.

Regarding the compression test, that also appears to be quite an undertaking unless I'm misunderstanding the manual.

ve9aa

Well-known member

Equipment

TG1860, BX2380 -backblade, bx2830 snowblower, fel, weight box,pallet forks,etc

You'll get it. The fellas here will walk you through how to ensure your fuel line is full of fuel end-to-end (and not have some water and/or air bubbles in it) and ensure it's pure fuel (under pressure) right at the injector...that's all very important.

Air and water with some diesel in it won't normally explode (if that's even the current issue)

(if that's even the current issue)

Air and water with some diesel in it won't normally explode

OK.

This is possibly my last try (not by choice...if I was a bachelor I'd pitch a tent next to the thing and call in sick until it was running.)

I'm going to head over, drain all the fuel, clean the filter, add fresh fuel, see if I can crack the injectors, crank the engine, and see if fuel starts to spray out. If it does, I'll reattach the glow plug jumper, let it sit for a minute (can I just leave it attached or will it overheat), and then give it another go.

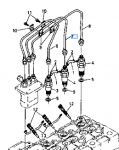

I saw a video online of a guy turning a little air bleeding knob. Based on the attached EV it looks like there is one on my model too. So I might try turning that also while cranking

This is possibly my last try (not by choice...if I was a bachelor I'd pitch a tent next to the thing and call in sick until it was running.)

I'm going to head over, drain all the fuel, clean the filter, add fresh fuel, see if I can crack the injectors, crank the engine, and see if fuel starts to spray out. If it does, I'll reattach the glow plug jumper, let it sit for a minute (can I just leave it attached or will it overheat), and then give it another go.

I saw a video online of a guy turning a little air bleeding knob. Based on the attached EV it looks like there is one on my model too. So I might try turning that also while cranking

Attachments

-

29.9 KB Views: 124

I got it! Just had to bleed the injectors. It was a cinch! This is the greatest feeling and it's all thanks to you guys! From the bottom of my heart, thank you!

I got it! Just had to bleed the injectors. It was a cinch! This is the greatest feeling and it's all thanks to you guys! From the bottom of my heart, thank you!

ve9aa

Well-known member

Equipment

TG1860, BX2380 -backblade, bx2830 snowblower, fel, weight box,pallet forks,etc

Russell King

Well-known member

Lifetime Member

Equipment

L185F, Modern Ag Competitor 4’ shredder, Rhino tiller, rear dirt scoop

I assume that you mean it is running now?!!!

If so that is excellent and congratulations on getting it going.

Be sure to get the air filter on before you run it much.

There is a valve on the injection pump that bleeds air out of the fuel lines. It looks like a bolt and large nut where the fuel line From filter attaches.

But you seem to have gotten it done so I won’t blather on.

Congratulations it is a great feeling when you hear it fire up.

If so that is excellent and congratulations on getting it going.

Be sure to get the air filter on before you run it much.

There is a valve on the injection pump that bleeds air out of the fuel lines. It looks like a bolt and large nut where the fuel line From filter attaches.

But you seem to have gotten it done so I won’t blather on.

Congratulations it is a great feeling when you hear it fire up.

Thank you!

I wound up draining all the fuel and cleaning out the fuel filter and bowl with kerosene, then refilling with diesel (treated with 911 for good measure). Then I cracked the bleeder valve and all the injectors and started cranking. First some fuel came out of the bleeder so I closed that, then one by one fuel bubbled out of the injectors. I knew we were in business once those bubbles came. Sure enough, the quantity and nature of the smoke changed significantly at that point. After closing the injectors and heating the glow plug, it fired up eagerly like it can’t wait to start working again. What catharsis!

After running it for about 30 minutes, I tested the loader controls. Unfortunately, in my excitement and haste I forgot to put the hood down, so even just a small manipulation of the loader wound up crunching the hood pretty bad and causing a few spots of permanent damage. Is the hood aluminum? It seemed quite brittle and cracked easily rather than bending like I assume steel would have. Whoopsies!

I drove it home, about a 6 mile drive, with 1 mile of that on a busy main road with no shoulder. It was a little nerve-racking and I definitely got some of the same stares that I usually give to people riding tractors on primary roads

Once home, I figured I’d give it a trial by fire and hauled a 24’ 16” log up a hill to be milled. Just barely made it, which means it should be able to handle all the other projects I have in store for it.

Minutes before shutting her down for the day, it mysteriously died and wouldn’t start again, seemingly from lack of fuel. Sure enough I checked the filter and it wasn’t filling up, and the tank is still full, so there appears to be a blockage in the bottom of the tank or between the tank and the first fuel line. I stuck some wire in there to try to free it up (unsuccessful) but didn’t think to blow into the line to try. Any other tips on that issue?

Once the fuel issue is resolved I will need to diagnose the ignition switch wiring, get a new element filter and pot filter (it's cracked and leaks about a drip every 5 seconds when the fuel is on), change the oil, and eventually give it a good scrubdown and possibly a paint or fluidfilm job. The tires are looking a little haggard too but I think I'll wait until they fail.

Is there a Kubota attachment interchange list?

I wound up draining all the fuel and cleaning out the fuel filter and bowl with kerosene, then refilling with diesel (treated with 911 for good measure). Then I cracked the bleeder valve and all the injectors and started cranking. First some fuel came out of the bleeder so I closed that, then one by one fuel bubbled out of the injectors. I knew we were in business once those bubbles came. Sure enough, the quantity and nature of the smoke changed significantly at that point. After closing the injectors and heating the glow plug, it fired up eagerly like it can’t wait to start working again. What catharsis!

After running it for about 30 minutes, I tested the loader controls. Unfortunately, in my excitement and haste I forgot to put the hood down, so even just a small manipulation of the loader wound up crunching the hood pretty bad and causing a few spots of permanent damage. Is the hood aluminum? It seemed quite brittle and cracked easily rather than bending like I assume steel would have. Whoopsies!

I drove it home, about a 6 mile drive, with 1 mile of that on a busy main road with no shoulder. It was a little nerve-racking and I definitely got some of the same stares that I usually give to people riding tractors on primary roads

Once home, I figured I’d give it a trial by fire and hauled a 24’ 16” log up a hill to be milled. Just barely made it, which means it should be able to handle all the other projects I have in store for it.

Minutes before shutting her down for the day, it mysteriously died and wouldn’t start again, seemingly from lack of fuel. Sure enough I checked the filter and it wasn’t filling up, and the tank is still full, so there appears to be a blockage in the bottom of the tank or between the tank and the first fuel line. I stuck some wire in there to try to free it up (unsuccessful) but didn’t think to blow into the line to try. Any other tips on that issue?

Once the fuel issue is resolved I will need to diagnose the ignition switch wiring, get a new element filter and pot filter (it's cracked and leaks about a drip every 5 seconds when the fuel is on), change the oil, and eventually give it a good scrubdown and possibly a paint or fluidfilm job. The tires are looking a little haggard too but I think I'll wait until they fail.

Is there a Kubota attachment interchange list?

Last edited:

Russell King

Well-known member

Lifetime Member

Equipment

L185F, Modern Ag Competitor 4’ shredder, Rhino tiller, rear dirt scoop

The fuel tank is probably rusted on the inside and clogging up the lines.

Try this: remove the fuel line to the filter and have a pan on the floor. See how much fuel is running out of the line. If not much then try loosening the fuel cap and see if it changes. If so remove the fuel cap completely. If the flow is still slow then screw the fuel cap on loosely and blow some compressed air (5 psi or so) through the line and expect it to rush out! Don’t blow too much or too long or you will make a mess out of the cap or blow the tank up.

See this thread for information

www.orangetractortalks.com

www.orangetractortalks.com

Please post pictures of the hood damage and the fuel filter. The hood is light weight steel and the filter on my tractor is like a oil filter and can’t be cleaned

Try this: remove the fuel line to the filter and have a pan on the floor. See how much fuel is running out of the line. If not much then try loosening the fuel cap and see if it changes. If so remove the fuel cap completely. If the flow is still slow then screw the fuel cap on loosely and blow some compressed air (5 psi or so) through the line and expect it to rush out! Don’t blow too much or too long or you will make a mess out of the cap or blow the tank up.

See this thread for information

L245dt fuel tank removal

Hey all, does anyone know of a good video or step by step instruction to remove the fuel tank from a l245dt? Mines full of sediment and i want to get it off to coat the inside. Thanks!

Please post pictures of the hood damage and the fuel filter. The hood is light weight steel and the filter on my tractor is like a oil filter and can’t be cleaned

Last edited:

Russell King

Well-known member

Lifetime Member

Equipment

L185F, Modern Ag Competitor 4’ shredder, Rhino tiller, rear dirt scoop

Modified the suggestion of air pressure in my post20 psi is a LOT of pressure to blow into a tank with the cap on it. 5 psi is what most manuals I’ve read suggest.

I cleared up the blockage with some compressed air but it still seems to be blocking up repeatedly. I haven't been able to get it started. The flow into the injectors is pretty weak. Russell I think I'm headed toward your route with the gas tank restoration. But first maybe I should siphon the fuel out and spray/suck out the bottom of the tank and see if I can get all the debris out first? It doesn't really look rusty, I would suspect contaminants in the fuel from the bottom of the gas can.

One interesting point. The cap for the fuel tank is original, but it doesn't fit. Not even close. The threads must have stripped out extremely bad because you can set the cap on top and the male/female threads won't even touch. Kind of odd.

I have attached four images. One image shows the damage to the hood. Apparently what I mistook for aluminum is actually some kind of coating over the steel hood (you can see where it cracked by the radiator hatch). The hood itself is actually fine save for a bend that is hard to see towards the front.

Another image shows the bigger issue, a widening gap where the hood hinge support attaches to the frame. This is one, but probably not the only factor causing the hood not to close completely. It's about 10" fore of where it should be.

The fuel filter image is attached. Yes, I know it's godawful. This is after the "cleaning," too! A replacement is on the way.

Also a picture indicating the front tire wear. The rears actually look OK, tread-wise.

One interesting point. The cap for the fuel tank is original, but it doesn't fit. Not even close. The threads must have stripped out extremely bad because you can set the cap on top and the male/female threads won't even touch. Kind of odd.

I have attached four images. One image shows the damage to the hood. Apparently what I mistook for aluminum is actually some kind of coating over the steel hood (you can see where it cracked by the radiator hatch). The hood itself is actually fine save for a bend that is hard to see towards the front.

Another image shows the bigger issue, a widening gap where the hood hinge support attaches to the frame. This is one, but probably not the only factor causing the hood not to close completely. It's about 10" fore of where it should be.

The fuel filter image is attached. Yes, I know it's godawful. This is after the "cleaning," too! A replacement is on the way.

Also a picture indicating the front tire wear. The rears actually look OK, tread-wise.

Attachments

-

602.8 KB Views: 133

-

592.4 KB Views: 144

-

807.6 KB Views: 145

-

509.9 KB Views: 145

Russell King

Well-known member

Lifetime Member

Equipment

L185F, Modern Ag Competitor 4’ shredder, Rhino tiller, rear dirt scoop

You can try to clean it out while on the tractor but you will have to siphon or pump the fuel out. I would try to drain it out through the fuel line and use a paint filter or something similar to catch the debris in.

Then you can use a magnet to see if it is rust.

The cap is available from the dealer and the tank may be available used from 007Kubotaguy on this forum.

The filter is a mess and good that is good you are replacing it it.

The tires are worn out and can be replaced with the same size or you may have to also replace the rear tires to keep the rolling circumference ratio the same.

The hood probably has body filler (bondo) that is cracking off. If the hood won’t close then just remove it for now.

You can also try to rig up a temporary fuel tank if you want to see it running again but it has to be above the injection pump and through a filter.

Then you can use a magnet to see if it is rust.

The cap is available from the dealer and the tank may be available used from 007Kubotaguy on this forum.

The filter is a mess and good that is good you are replacing it it.

The tires are worn out and can be replaced with the same size or you may have to also replace the rear tires to keep the rolling circumference ratio the same.

The hood probably has body filler (bondo) that is cracking off. If the hood won’t close then just remove it for now.

You can also try to rig up a temporary fuel tank if you want to see it running again but it has to be above the injection pump and through a filter.

Great. I'm awaiting a quote on the front tire replacements. Sounds like an expensive proposition, I might just wait until they're totally unusable.

I've got an aftermarket replacement cap in my cart, hoping that the tank's male threads are OK. Would the lack of a tight-fitting cap affect fuel flow? I noticed a little rubber pump bubble on the bottom of the cap that seemed like it served a function. If not, I might just tape the threads a bit to seal it better.

The hood closes enough to close the front frame latch thing (?) so it's really not a functional issue, just annoying and bothers me.

My father mentioned that I should change the oil, as he implied that he never has (!) Is it about as easy on this tractor as on a passenger car? Can I be lazy and just replace the oil filter, or is that kind of pointless without doing the whole oil change? What about the filters for non-engine oil, should I change those too?

At this point I should start strategizing on the ignition issue, too. I assume just test the wires from the battery up until I find a dead spot? I have the wiring diagram...but...

And you thought you were done because it started up! Haha

I've got an aftermarket replacement cap in my cart, hoping that the tank's male threads are OK. Would the lack of a tight-fitting cap affect fuel flow? I noticed a little rubber pump bubble on the bottom of the cap that seemed like it served a function. If not, I might just tape the threads a bit to seal it better.

The hood closes enough to close the front frame latch thing (?) so it's really not a functional issue, just annoying and bothers me.

My father mentioned that I should change the oil, as he implied that he never has (!) Is it about as easy on this tractor as on a passenger car? Can I be lazy and just replace the oil filter, or is that kind of pointless without doing the whole oil change? What about the filters for non-engine oil, should I change those too?

At this point I should start strategizing on the ignition issue, too. I assume just test the wires from the battery up until I find a dead spot? I have the wiring diagram...but...

And you thought you were done because it started up! Haha

ve9aa

Well-known member

Equipment

TG1860, BX2380 -backblade, bx2830 snowblower, fel, weight box,pallet forks,etc

Russell King

Well-known member

Lifetime Member

Equipment

L185F, Modern Ag Competitor 4’ shredder, Rhino tiller, rear dirt scoop

The engine oil and filter should be changed now that you have it running. That is easier to do than any car. There are probably two drain plugs, one on each side of the drive shaft from the front axle. There will be a copper crush washer underneath the head of the plug. I would purchase new ones to avoid leaks.

The plugs will look like large bolt heads, probably about 19 mm socket will fit them. I suggest that you paint them red for future identification

USE diesel rated engine oil only! Currently the description is CJ or CK I think, you’re not able to get the ratings in the old manual like CD.

You may as well invest in a large metric socket set at the largest size at 30mm and down, 1/2 or 3/4(preferably) drive. 3/8 drive can be used for the small bolts but most bolts will be too large for that size.

Then you will need to change the coolant fluid and then the transmission (hydraulic) fluid and front axle lubricant.

You can use universal tractor transmission and hydraulic fluid in the transmission like Tractor Supply Traveler brand or the Kubota UDT.

Only the engine oil and filter needs changed right now.

I would plan on changing all filters and fluids so that you know that they are good and freshly done. You don’t need to fret or rush but just get it done.

I would suggest you get the wiring redone at your leisure over time. (Officially diesels don’t have an ignition system)

The plugs will look like large bolt heads, probably about 19 mm socket will fit them. I suggest that you paint them red for future identification

USE diesel rated engine oil only! Currently the description is CJ or CK I think, you’re not able to get the ratings in the old manual like CD.

You may as well invest in a large metric socket set at the largest size at 30mm and down, 1/2 or 3/4(preferably) drive. 3/8 drive can be used for the small bolts but most bolts will be too large for that size.

Then you will need to change the coolant fluid and then the transmission (hydraulic) fluid and front axle lubricant.

You can use universal tractor transmission and hydraulic fluid in the transmission like Tractor Supply Traveler brand or the Kubota UDT.

Only the engine oil and filter needs changed right now.

I would plan on changing all filters and fluids so that you know that they are good and freshly done. You don’t need to fret or rush but just get it done.

I would suggest you get the wiring redone at your leisure over time. (Officially diesels don’t have an ignition system)

Also you should have a spring under the fuel filter that sits in the bottom of the fuel cup. Many times they are missing. This allows the fuel filter to drop down and fuel passes through without getting filtered.