As to why not 'factory standard equipment', not every tractor owner uses the 3PH ! Heck, my BH has never been off, 3PH kit never installed in 6 years. Some tractors are 'loader' configured so no PTO out back OR 3PH rockshaft. . Back in '57 the option was 1 hole bracket or 3 hole bracket. None was factory standard.

The MX in #050 seems to have 'lots' of room to get bolts in. Easy access to the rear, worst case for fronts, drill 2 holes in the cab floor, use plastic cap plugs to fill the holes.

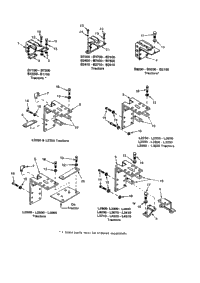

I used 3/8" plywood to make the 'pattern' for my 3 hole version top link plates. Since I fixed friend's CNC machine, he made them for me. The 'trick' is to get the 'numbers' into the CNC right,after that maing 1,10,100 is the same..load steel, press 'go' button,have a coffee.