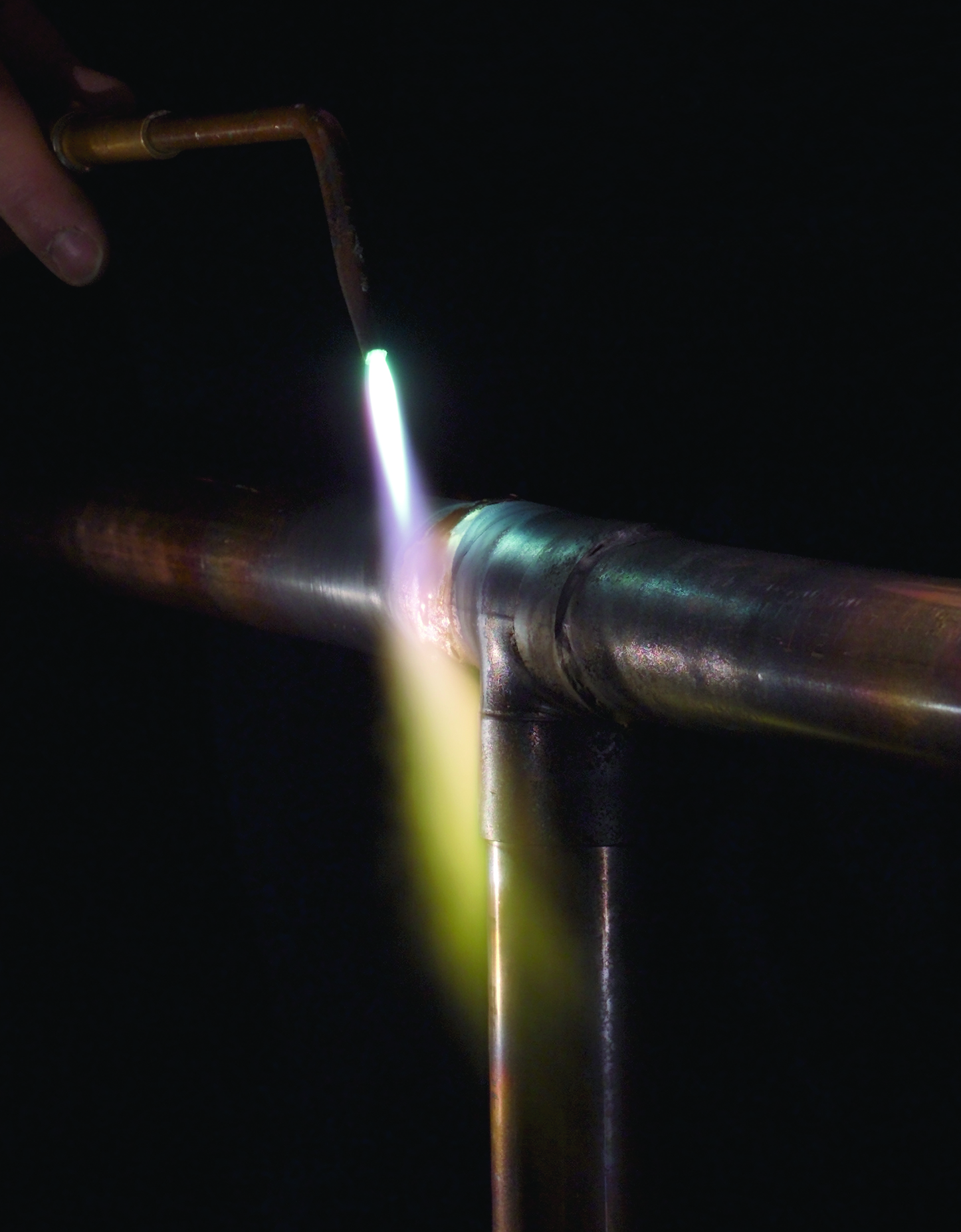

For the actual 'patch',find similar thickness steel plate,though 3/16 would be fine. Make a cardboard template and note where the bends are and bend in a vice 'as required'.Make the patch piece about 2mm (1/16" smaller). Now put block on the other side and use whatever steel you have to support the patch from the inside WITH a sheet of aluminum between the patch and the support. Bronze won't stick to aluminum, so if any 'filler' bronze drips onto it, NOT a problem.

Pretty sure even 1/8" sheet steel would be fine and a lot easier to fabricate into a patch. You could maybe use 2 pieces to 'fill' the thickness of the block. Just be sure to clean the 'patch' really,really well....you want it shiny and NO oil on it. For the actual bonding, you'll probably want to 'tack braze' corners then 1/2 the distance, then 1/2 again not a continuous flow of bronze to minimize warping of the patch.

Pretty sure even 1/8" sheet steel would be fine and a lot easier to fabricate into a patch. You could maybe use 2 pieces to 'fill' the thickness of the block. Just be sure to clean the 'patch' really,really well....you want it shiny and NO oil on it. For the actual bonding, you'll probably want to 'tack braze' corners then 1/2 the distance, then 1/2 again not a continuous flow of bronze to minimize warping of the patch.