NEPA Guy

Member

Lifetime Member

Equipment

B2650HSDC, Spacers, FEL, BH, Snowblower, Snowplow, PBar, Forks

I was doing the first 50 hour service on the tractor. Swapped the oil and filter, no problem.

Next up is to change the transmission oil filter [HST] and the hydraulic oil filter.

Although the manual says not to swap the fluid till 400 hours, it seems cleaner to drain the fluid and then change the filters. I had done this before on a B3350 and noticed some shavings when I drained it, so I get the satisfaction of knowing I've got the cleanest fluid possible.

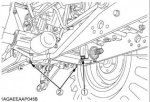

I removed bolt #1 and drained the transmission fluid from that spot. When I put the bolt back in I hand screwed it in and then used my wrench to tighten it and then it just went loose, kept spinning, and not tightening anymore.

I loosened it and took it off and when I did a part of the thread fell off the top of the bolt. (see pictures)

When I looked closely, I also noticed that there was this grey matter wedged in the thread of the bolt.

It's hard to see but I tried to get a clear shot of the drain hole. I'm not quite sure what to do. I tried to thread it back in by hand but now I'm meeting resistance. I don't want to force it back in and make it worse, and not sure if just a new bolt will fix my problem or if the drain hole thread is defective or needs to be cleaned? Please don't tell me it has to be re-threaded.

Also, should I be replacing the washers on the bolts, It appears there's a rubber ring on the inside of the washer . I replaced the copper washers on the oil bolts.

I didn't remove and drain bolts #2, or swap the filters yet, it's getting late.

I've swapped fluids hundreds of times. This has never happened to me before.

Any advice would be appreciated.

Next up is to change the transmission oil filter [HST] and the hydraulic oil filter.

Although the manual says not to swap the fluid till 400 hours, it seems cleaner to drain the fluid and then change the filters. I had done this before on a B3350 and noticed some shavings when I drained it, so I get the satisfaction of knowing I've got the cleanest fluid possible.

I removed bolt #1 and drained the transmission fluid from that spot. When I put the bolt back in I hand screwed it in and then used my wrench to tighten it and then it just went loose, kept spinning, and not tightening anymore.

I loosened it and took it off and when I did a part of the thread fell off the top of the bolt. (see pictures)

When I looked closely, I also noticed that there was this grey matter wedged in the thread of the bolt.

It's hard to see but I tried to get a clear shot of the drain hole. I'm not quite sure what to do. I tried to thread it back in by hand but now I'm meeting resistance. I don't want to force it back in and make it worse, and not sure if just a new bolt will fix my problem or if the drain hole thread is defective or needs to be cleaned? Please don't tell me it has to be re-threaded.

Also, should I be replacing the washers on the bolts, It appears there's a rubber ring on the inside of the washer . I replaced the copper washers on the oil bolts.

I didn't remove and drain bolts #2, or swap the filters yet, it's getting late.

I've swapped fluids hundreds of times. This has never happened to me before.

Any advice would be appreciated.

Attachments

-

21.4 KB Views: 1,890

-

85.9 KB Views: 842

-

86.7 KB Views: 879

-

39.9 KB Views: 781