As the title said, my rear tire as slid closer to the wheel well. It is actually rubbing on the wheel well with the edge of the rim. Probably slid in 1 to 1.25 inches.

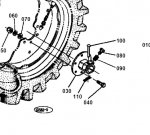

I jacked it up and the wheel is tight on the shaft and I couldn't loosen the bolt (didn't spend much time with it as it was getting dark). What is the best way to slide it back into position? Take the wheel off the hub and put a big gear puller on it and get it to slide, bang on it with rubber/plastic mallet? Pry on something?

I just am short on time and don't want to waste any time I have.

Thanks,

Jay

I jacked it up and the wheel is tight on the shaft and I couldn't loosen the bolt (didn't spend much time with it as it was getting dark). What is the best way to slide it back into position? Take the wheel off the hub and put a big gear puller on it and get it to slide, bang on it with rubber/plastic mallet? Pry on something?

I just am short on time and don't want to waste any time I have.

Thanks,

Jay