Is there interest in another SSQA fabrication thread? I searched through a ton of them, and didn't see one that showed some details that are needed. I have a new (to me) LA302 on my tractor, and want to convert it to SSQA.

There are several goals. First, I like to design/build projects. Second, I want an easy way to switch from forks to bucket and possibly other implements (snow blade?).

I know that the LA302 has limited lift capacity and SSQA will add dead weight, eating in to the useful lift capacity. So, that leads to another goal of keeping my adapter as light as feasible.

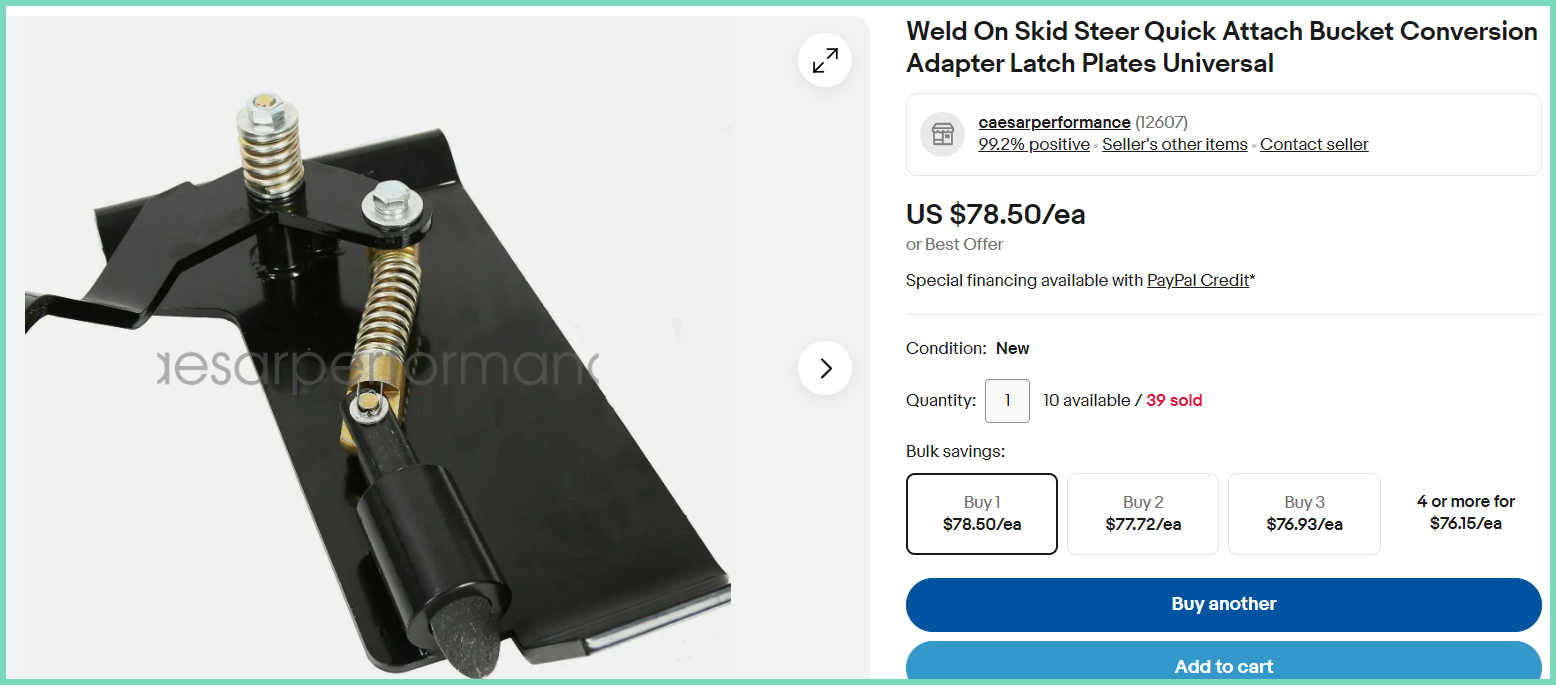

I have a set of these in-hand now.

So, the first step seems to be to figure out where to locate the brackets and holes to pin it to the LA302. To do that, I put together a mock-up by tack welding some scrap 1/8" steel to the latch plate, like this:

After a few attempts, it looks like the above is the best location for the pins - it minimizes the pin-to-front-face dimension, which seems like a good goal, but still allows full extension and retraction of the curl cylinders with no colliding parts.

There are several goals. First, I like to design/build projects. Second, I want an easy way to switch from forks to bucket and possibly other implements (snow blade?).

I know that the LA302 has limited lift capacity and SSQA will add dead weight, eating in to the useful lift capacity. So, that leads to another goal of keeping my adapter as light as feasible.

I have a set of these in-hand now.

So, the first step seems to be to figure out where to locate the brackets and holes to pin it to the LA302. To do that, I put together a mock-up by tack welding some scrap 1/8" steel to the latch plate, like this:

After a few attempts, it looks like the above is the best location for the pins - it minimizes the pin-to-front-face dimension, which seems like a good goal, but still allows full extension and retraction of the curl cylinders with no colliding parts.

Last edited: