M9540 hydraulic problem

- Thread starter Whitaker Farms

- Start date

Have seen 3ph valve stuck, inside the position control valve assembly-and this will allow oil to basically bypass, causing low pressure in the rest of the system. That was on an M9540.

Have also seen a pump or two wear out and cause EXACTLY what you're describing. Low pressure at idle, rev it to rated RPM and it'll be close to normal. Back to idle, saw 500-800 psi which is way low; and will affect the loader and 3ph. When the pumps wear, generally I see them with worn housings. When it wears like that it leaks internally and can't build a lot of pressure like it was designed to. Take the rotors out and they have a bushing in the housing where the rotor shafts ride, and they're usually completely gone and worn into the housing. I don't know why. Sometimes I want to think that maybe some point in the tractor's life the oil was overheated. Or not changed often enough. At that point, it's cheaper to replace the assembly then it is to rebuild it so normally if I see that, I just price out a pump assembly. Last one I did (about 3 months ago) the pump part number superceded to a new number. Don't know why, dealer never tells me mainly because they usually don't know. Sometimes they change the color. Maybe they changed the material that the pump is made out of. Never know, all I know is that it had a new part number.

You'll need a pressure gauge to diagnose. According to WSM, it's done at the rear remotes. You'll want to see around 1800-2000 psi minimum at idle speed and IIRC around 2500 at rated engine RPM (you will want to double check as I'm going off of memory). They don't go into much diagnosis beyond that. IIRC it says to check psi, then adjust the relief if the psi is low. In every case I've dealt with, I couldn't adjust it enough to get it back up, which is a dead giveaway that there's a leak somewhere in the system.

There is no rubber suction pipe. All metal, comes out of the sump in the trans case and goes directly to the hyd pump. The tube is about 1" diameter and is a hard 90 deg angle after it comes out of the sump. There are o-rings, one at the pump side and one at the suction side, if they are "bad", you'll know it. Usually see some oil around them. Very uncommon anyway. I have seen one instance where debris had crushed the suction pipe but that pipe is pretty stout, so if that happens, you'll have other problems too, like leak, etc.

Have also seen a pump or two wear out and cause EXACTLY what you're describing. Low pressure at idle, rev it to rated RPM and it'll be close to normal. Back to idle, saw 500-800 psi which is way low; and will affect the loader and 3ph. When the pumps wear, generally I see them with worn housings. When it wears like that it leaks internally and can't build a lot of pressure like it was designed to. Take the rotors out and they have a bushing in the housing where the rotor shafts ride, and they're usually completely gone and worn into the housing. I don't know why. Sometimes I want to think that maybe some point in the tractor's life the oil was overheated. Or not changed often enough. At that point, it's cheaper to replace the assembly then it is to rebuild it so normally if I see that, I just price out a pump assembly. Last one I did (about 3 months ago) the pump part number superceded to a new number. Don't know why, dealer never tells me mainly because they usually don't know. Sometimes they change the color. Maybe they changed the material that the pump is made out of. Never know, all I know is that it had a new part number.

You'll need a pressure gauge to diagnose. According to WSM, it's done at the rear remotes. You'll want to see around 1800-2000 psi minimum at idle speed and IIRC around 2500 at rated engine RPM (you will want to double check as I'm going off of memory). They don't go into much diagnosis beyond that. IIRC it says to check psi, then adjust the relief if the psi is low. In every case I've dealt with, I couldn't adjust it enough to get it back up, which is a dead giveaway that there's a leak somewhere in the system.

There is no rubber suction pipe. All metal, comes out of the sump in the trans case and goes directly to the hyd pump. The tube is about 1" diameter and is a hard 90 deg angle after it comes out of the sump. There are o-rings, one at the pump side and one at the suction side, if they are "bad", you'll know it. Usually see some oil around them. Very uncommon anyway. I have seen one instance where debris had crushed the suction pipe but that pipe is pretty stout, so if that happens, you'll have other problems too, like leak, etc.

My guess is faulty relief valve is problem more than worn hyd pump. Did you state how many hrs are on tachometer and I overlooked it? Are you 100% sure rear remotes & 3 pt control levers are in neutral?I guess so. Our M5030 has what your talking about but it's never caused a problem. I am not sure what else it could be but the pump. I think I'm going to pull the pump and see if it shows any signs of wear.

Put a flow rater in the remotes and see if it will achieve max flow at rated Rpms and pressure if not then it's your pump. If all of your hydraulics are affected except steering and you have good fluid and filters and no damage to suction lines then you probably need a pump.

Sorry for not getting back but we've been really busy and just got back to it last night. I talked to 3 diff dealers and all anyone could say is it needs a pump, so I pulled mine and inspected it. Everything inside looked good. The case had about 0.001" of wear in the steering and hydraulic section. The dealers couldn't tell me any clearances and the service manual doesn't either so against my better judgement I ordered a pump and installed it. Nothing changed. At this point I was pissed. I wasted $1350. I started disassembling the hydraulic system. The loader valve was first since it's the easiest to get to. When I pulled that relief valve one of the orings and spacers had a spot that was cut/washed. I put a new oring on it and problem solved. So does anybody need a pump. I'll sell the new one or the used one and guarantee either to work. Make an offer.

You were right. I didn't realize the relief on the loader valve was In series with all the hydraulics. I thought it was just for the loader. Apparently when the oring went it was letting it just push pressure back to the tank.My guess is faulty relief valve is problem more than worn hyd pump. Did you state how many hrs are on tachometer and I overlooked it? Are you 100% sure rear remotes & 3 pt control levers are in neutral?

Thanks for update & I'm glad you solved your tractor's problem.

Many,many hyd pumps over the yrs have been replaced only to find out old pump wasn't the problem. This is why "proper diagnostics" is very important. I served 13 yrs as a JD dealer service manager so I learned to perform good diagnostic procedures.

I'm not trying to add salt to your wound but evidently you didn't read or maybe not comprehend Dave_eng's post #9 which stated hyd oil was 1st directed to FEL valve/relief then routed to rear of tractor to scv/3pt relief valve.

Many,many hyd pumps over the yrs have been replaced only to find out old pump wasn't the problem. This is why "proper diagnostics" is very important. I served 13 yrs as a JD dealer service manager so I learned to perform good diagnostic procedures.

I'm not trying to add salt to your wound but evidently you didn't read or maybe not comprehend Dave_eng's post #9 which stated hyd oil was 1st directed to FEL valve/relief then routed to rear of tractor to scv/3pt relief valve.

Yessir. I just re-read it and I don't know what happened. I responded to it but I guess I read it to fast or something.Thanks for update & I'm glad you solved your tractor's problem.

Many,many hyd pumps over the yrs have been replaced only to find out old pump wasn't the problem. This is why "proper diagnostics" is very important. I served 13 yrs as a JD dealer service manager so I learned to perform good diagnostic procedures.

I'm not trying to add salt to your wound but evidently you didn't read or maybe not comprehend Dave_eng's post #9 which stated hyd oil was 1st directed to FEL valve/relief then routed to rear of tractor to scv/3pt relief valve.

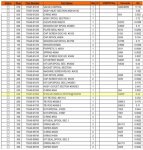

I'm having the exact same problem on the exact same tractor and trying to confirm the "relief valve" referenced above is on the rear of the tractor below the rear remotes (see pic) or a component/valve that is associated with and directly on the loader control valve near the middle of the tractor. Any help clarifying would be greatly appreciated.

Attachments

-

70.9 KB Views: 2,751

The relief valve they are talking about here is the one in the loader valve. The one you are pointing to is the relief valve for the remotes and TPH. It only affects the remotes and the TPH. The relief valve in the loader affects the loader as well as the remotes and TPH.I'm having the exact same problem on the exact same tractor and trying to confirm the "relief valve" referenced above is on the rear of the tractor below the rear remotes (see pic) or a component/valve that is associated with and directly on the loader control valve near the middle of the tractor. Any help clarifying would be greatly appreciated.

No not that relief valve near the rear remotes. On the loader valve there is a relief valve.I'm having the exact same problem on the exact same tractor and trying to confirm the "relief valve" referenced above is on the rear of the tractor below the rear remotes (see pic) or a component/valve that is associated with and directly on the loader control valve near the middle of the tractor. Any help clarifying would be greatly appreciated.

Because the rear of the tractor is fed from the power beyond port on the loader valve, the loader's relief valve can and will affect what the rear of the tractor can receive as far as pressure is concerned.

The relief valve on the rear can only make pressures lower than the loader relief but never higher. If as happened on the previous tractor, the loader relief was compromised, nothing can be done on the rear of the tractor as it will have limited pressure

Dave

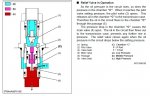

Thanks Dave. That's what I thought but have been unable to find o-rings/spacers within the schematic (attached) associated with the relief valve. Am I missing something ? ? ?

Attachments

-

57.1 KB Views: 1,816

-

112.2 KB Views: 610

Last edited:

The relief valve they are talking about here is the one in the loader valve. The one you are pointing to is the relief valve for the remotes and TPH. It only affects the remotes and the TPH. The relief valve in the loader affects the loader as well as the remotes and TPH.

IMHO the control valve parts schematic posted by Lerch is for a LA1353A FEL control valve not tractor scv or 3 pt.

The last one he posted is, the first one he posted isn't.The relief valve they are talking about here is the one in the loader valve. The one you are pointing to is the relief valve for the remotes and TPH. It only affects the remotes and the TPH. The relief valve in the loader affects the loader as well as the remotes and TPH.

The relief valve is replaced as one part as it is a pilot operated one and complicated. You replace the complete valve for $136.00Thanks Dave. That's what I thought but have been unable to find o-rings/spacers within the schematic (attached) associated with the relief valve. Am I missing something ? ? ?

75567-61600

Vendor Kubota

Messick's Price $137.69

It will look like this one. Unlike other relief valves on the smaller tractors, these are not adjusted with spacers.

Dave

Attachments

-

133.1 KB Views: 714

Im not positive this is your problem, but i had issues simmular with broken orings found on the pump connections. There cheap and easily changed...worth a try. That is if your model has orings.

The last one he posted is, the first one he posted isn't.

Thanks for correcting me. I overlooked Lerch's 1st relief valve schematic post.

Thanks for all the suggestions. This tractor is new to me, so I do not know when the hydraulic fluid was last serviced or what type was used. While it appears the hydraulic fluid looks good and Kubota filters were used, though date/hours where not written on the filter, the dealer recommends I service the hydraulics with Super UDT and Kubota filters first to see if that resolves my issue.

I probably will go ahead and service the hydraulics, but the fact that the issue is intermittent and varies per command (lift, tilt up, or tilt down) I'm assuming this will not solve my problem.

Since the original thread author referenced the same model and was trying to identify the respective O-rings/spacers he replaced resolve this issue.

It looks like if a $400+ hydraulic service does not resolve, I will have a $140 valve replacement as a next step.

Any other thoughts on troubleshooting steps/order ? ? ?

I probably will go ahead and service the hydraulics, but the fact that the issue is intermittent and varies per command (lift, tilt up, or tilt down) I'm assuming this will not solve my problem.

Since the original thread author referenced the same model and was trying to identify the respective O-rings/spacers he replaced resolve this issue.

It looks like if a $400+ hydraulic service does not resolve, I will have a $140 valve replacement as a next step.

Any other thoughts on troubleshooting steps/order ? ? ?

It will take just under 15 gallons to change the fluid and 2 filters. As a matyter of not knowing when it was done or what fluid was used, I'd change it as a matter of consequence and I'd also change the front axle fluid, center section and outboard planetaries and engine oil too. Always better to start with a clean slate with a used unit.

I use 85-90 GL4-5 hypoid oil in both my M's but what you use is your choice. I do it for shpck load reasons.

I use Chevron All Weather Synthetic THF fluid in both my M's. It's Kubota certified com[patible and costs about the same in 5 gallon pails/ Again, personal preference. Chevron is hard to get in some areas.

Irregardless, I'd be changing everything and filters and while you are at it, check the air filter and replace that as well if it looks dirty.

I use 85-90 GL4-5 hypoid oil in both my M's but what you use is your choice. I do it for shpck load reasons.

I use Chevron All Weather Synthetic THF fluid in both my M's. It's Kubota certified com[patible and costs about the same in 5 gallon pails/ Again, personal preference. Chevron is hard to get in some areas.

Irregardless, I'd be changing everything and filters and while you are at it, check the air filter and replace that as well if it looks dirty.

UPDATE. I finally got done with winter feeding and while this loader issue was inconvenient, but manageable, I now have it in my shop where I can work.

1. Fully service the hydraulics with all Kubota parts and fluids. DID NOT FIX.

2. Dealer recommended work on the loader control valve spool with the steel balls in it. Stated they can get gummed/rust up and stick. They were not bad, but cleaned thoroughly and put back. DID NOT FIX.

3. Dealer recommended to remove relief valve (all one piece, self contained as shown above), inspect, and clean thoroughly in parts washer. I did that and reinstalled. DID NOT FIX. Since that relief valve in all one piece/self contained, I have no way to tell if the inner-components are faulty. . . but the two outside moveable parts operated freely.

I have no leaks around pump or loader control valve.

I did notice today that a high RPMs, when it stops, if I quickly rock joystick opposite and then right back, a lot of times it will come out of it and stay in motion at high RPMs. Similarly, if it stops and I lower the RPMs to get moving again and raise the RPMs while in motion, it continues to work properly. In case that helps troubleshooting.

Thoughts ? ? ?

1. Fully service the hydraulics with all Kubota parts and fluids. DID NOT FIX.

2. Dealer recommended work on the loader control valve spool with the steel balls in it. Stated they can get gummed/rust up and stick. They were not bad, but cleaned thoroughly and put back. DID NOT FIX.

3. Dealer recommended to remove relief valve (all one piece, self contained as shown above), inspect, and clean thoroughly in parts washer. I did that and reinstalled. DID NOT FIX. Since that relief valve in all one piece/self contained, I have no way to tell if the inner-components are faulty. . . but the two outside moveable parts operated freely.

I have no leaks around pump or loader control valve.

I did notice today that a high RPMs, when it stops, if I quickly rock joystick opposite and then right back, a lot of times it will come out of it and stay in motion at high RPMs. Similarly, if it stops and I lower the RPMs to get moving again and raise the RPMs while in motion, it continues to work properly. In case that helps troubleshooting.

Thoughts ? ? ?

Last edited: