Your probably right but I’m that guy that chases every lead with whatever it is I’m doing to get the results I’m looking for.That person (Sterno) has not been on this site since 2021 so I doubt you will get anywhere with this.

Is there interest in a DIY Loader Kit for B6100/B7100?

- Thread starter Sterno

- Start date

If you send him a personal message he may get an email and reply even if he was not here on the forum for years.Your probably right but I’m that guy that chases every lead with whatever it is I’m doing to get the results I’m looking for.

If you have success contacting him I would appreciate if you could post this here.

I will 100% share everything I find, fab, build and even screw up so we all can have a good experience or laugh with my project.If you send him a personal message he may get an email and reply even if he was not here on the forum for years.

If you have success contacting him I would appreciate if you could post this here.

barts

Active member

Equipment

4wd B5100 w/ FEL, box blade, JD110 TLB, WC68 chipper, log arch, brush mower.

I built a subframe to fit a B219 loaderonto our B5100. It's a matter of figuring out where everything neededs to be:How is the CAD file coming along? I recently bought a very clean B219 loader but will need to build a subframe for my 1980 B6100D tractor. The quick attach feature of course really gets my attention and expands the use of the tractor many fold. I would appreciate the file for my own uses on my own equipment. I have access to a water jet cutter and full line machine shop with bending and shaping capabilities. Thank you in advance. If for some reason this isn't going to become a reality plz let me know that as well. Thx again!

Outstanding!! Thank you for the pictures. This is very much what I had imagined the subframe I am going to build. Tying into the bolts that hold the ROP on and moving forward from there along with a couple of cross supports were exactly where I figured I’d end up. I really appreciate the sharing of information. Doesn’t it make a body feel good to accomplish something like this? It does for me!I built a subframe to fit a B219 loaderonto our B5100. It's a matter of figuring out where everything neededs to be:

View attachment 155702 View attachment 155703

Great job !I built a subframe to fit a B219 loaderonto our B5100. It's a matter of figuring out where everything neededs to be:

View attachment 155702 View attachment 155703

But I have a question: would the frame of a tractor not be strong enough for the loader forces? I understand that the forces from the loader have to be transferred into the frame and the axles eventually. But is an additional subframe like this always required?

Russell King

Well-known member

Lifetime Member

Equipment

L185F, Modern Ag Competitor 4’ shredder, Rhino tiller, rear dirt scoop

There is NOT a frame on many of these tractors, the engine and transmission case act as the frame. They are not designed for the pushing forces of the FEL.

The short answer is YES it’s required. But to explain why it’s needed will be helpful for better understanding. The frame stiffens the entire tractor and carries the stress much better because it’s made from plate steel typically. The “body” of the tractor is not designed to withstand the stresses from the loader or the back hoe both along the frame length and across the frame in a more shear style of stress. Imagine too much gravel in the middle of a trailer. The trailer fails and breaks in half due to the stress caused by the weight of the gravel. Additional frame work is nearly always required because the tractor isn’t designed for the forces being put in it but the loader or the backhoe attached to it.Great job !

But I have a question: would the frame of a tractor not be strong enough for the loader forces? I understand that the forces from the loader have to be transferred into the frame and the axles eventually. But is an additional subframe like this always required?

barts

Active member

Equipment

4wd B5100 w/ FEL, box blade, JD110 TLB, WC68 chipper, log arch, brush mower.

You can think of the loader as trying to tip the tractor forward so that it's balancing on the front wheels. W/o a subframe, the only connection between the front wheels and engine and the rear wheels is the transmission, so the top bolts would be in tension and the bottom ones in compression. Here's a photo of our B5100 sans subframe; there's no way that tiny transmission would be strong enough.

Here's a picture of the tractor w/ the loader and subframe; you may be able to see how the loader forces are tied into the truss formed by the combination of the transmission and the subframe.

Here's a picture of the tractor w/ the loader and subframe; you may be able to see how the loader forces are tied into the truss formed by the combination of the transmission and the subframe.

@barts : great, thank you very much for the pictures !

I can see now why the subframe is required.

The tractor I have in mind has a frame already and an additional subframe would be difficult to do. And it would be a tiny loader anyway. I have to see if I just reinforce the frame on the inside or maybe do nothing and risk it.

I can see now why the subframe is required.

The tractor I have in mind has a frame already and an additional subframe would be difficult to do. And it would be a tiny loader anyway. I have to see if I just reinforce the frame on the inside or maybe do nothing and risk it.

torch

Well-known member

Equipment

B7100HSD, B2789, B2550, B4672, 48" cultivator, homemade FEL and Cab

DON'T RISK IT.

I strongly recommend that anyone designing/building their own subframe based on pictures read my experience here.

It is not just the FEL forces need to be transferred to the rear axle, but also that the transmission/engine joint needs to be reinforced. The B7100 has a steel adapter plate between the engine and transmission that can flex and warp. It is not outwardly noticeable, but WILL destroy clutches (as I discovered to my chagrin).

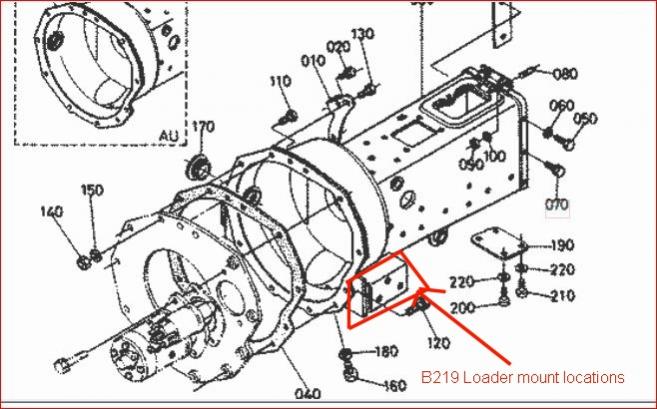

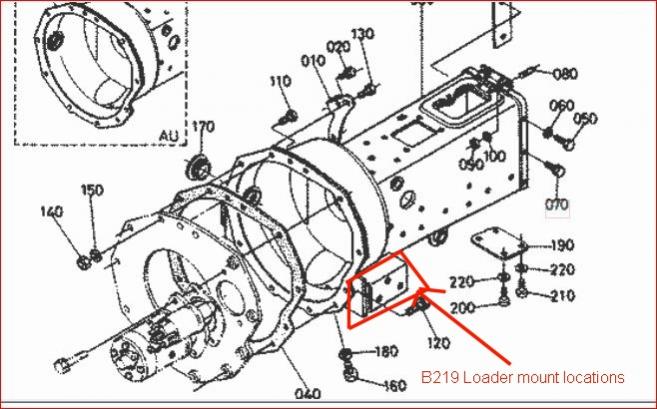

I based my original design on images and explanations of the later Kubota design, that braces the rear axle to the front of the transmission (image courtesy of North Idaho Wolfman). You can see it bolts to the front of the transmission:

(It's hard to say for certain due to angle and distance, but Bart's B5100 photo above may be of this design)

But this image (courtesy Lil Foot) of the older design shows the subframe extending well past that joint, bolting to the rear of the engine instead:

I believe the earlier design is superior. But if you have a later tractor that has the mounting points at the transmission, use both. It may be overkill, but better safe than sorry and way easier to add some steel now than change a clutch later! Mine is now bolted on both sides of the joint and so far, so good...

I strongly recommend that anyone designing/building their own subframe based on pictures read my experience here.

It is not just the FEL forces need to be transferred to the rear axle, but also that the transmission/engine joint needs to be reinforced. The B7100 has a steel adapter plate between the engine and transmission that can flex and warp. It is not outwardly noticeable, but WILL destroy clutches (as I discovered to my chagrin).

I based my original design on images and explanations of the later Kubota design, that braces the rear axle to the front of the transmission (image courtesy of North Idaho Wolfman). You can see it bolts to the front of the transmission:

(It's hard to say for certain due to angle and distance, but Bart's B5100 photo above may be of this design)

But this image (courtesy Lil Foot) of the older design shows the subframe extending well past that joint, bolting to the rear of the engine instead:

I believe the earlier design is superior. But if you have a later tractor that has the mounting points at the transmission, use both. It may be overkill, but better safe than sorry and way easier to add some steel now than change a clutch later! Mine is now bolted on both sides of the joint and so far, so good...

Last edited:

I intend to pattern my subframe after the one in the photo (courtesy of Lil’ Foot).DON'T RISK IT.

I strongly recommend that anyone designing/building their own subframe based on pictures read my experience here.

It is not just the FEL forces need to be transferred to the rear axle, but also that the transmission/engine joint needs to be reinforced. The B7100 has a steel adapter plate between the engine and transmission that can flex and warp. It is not outwardly noticeable, but WILL destroy clutches (as I discovered to my chagrin).

I based my original design on images and explanations of the later Kubota design, that braces the rear axle to the front of the transmission (image courtesy of North Idaho Wolfman). You can see it bolts to the front of the transmission:

(It's hard to say for certain due to angle and distance, but Bart's B5100 photo above may be of this design)

But this image (courtesy Lil Foot) of the older design shows the subframe extending well past that joint, bolting to the rear of the engine instead:

I believe the earlier design is superior. But if you have a later tractor that has the mounting points at the transmission, use both. It may be overkill, but better safe than sorry and way easier to add some steel now than change a clutch later! Mine is now bolted on both sides of the joint and so far, so good...

torch

Well-known member

Equipment

B7100HSD, B2789, B2550, B4672, 48" cultivator, homemade FEL and Cab

Swede1962,-

Sorry for any confusion, I should have quoted the comment I was replying to. My response was aimed at this:

Sorry for any confusion, I should have quoted the comment I was replying to. My response was aimed at this:

(emphasis added)I have to see if I just reinforce the frame on the inside or maybe do nothing and risk it.

Any chance you have completed the upgrades you spoke about concerning a quick change setup on your B219? I'd love to see as much of it as possible. I have a B219 and want to do the same thing. Thanks!!I guess i never saw this thread the first time around. That's a nice looking loader. I have a B219 and there's actually not much about it that bothers me, other than the fact that the pin holes are not great nowadays because they are nothing more than holes in some ~3/16" or so thick material. I just redid one for my friend and welded 'repair washers' into basically every pin hole which a little more than doubled the contact area (as well as putting hole back to correct spec).

I think the main thing i would choose to change about my b219 if i could just snap my fingers and have it, is all to do with the loader valve. 1, relocate it a bit so it interferes less with getting on/off the tractor (it's not terrible but could be better) and 2, add 'valve features' like drilled for power beyond and a sleeve is actually available, or sectional and new sections still exist, or internal load check valving, etc. Just for the whole valve situation to be 'nicer'. I don't mind anything about the towers/arms/subframe. It's just my opinion but i think EVERY loader built in the present day should have quick attach, whether it's ssqa or the mini-skid QA. I like the JDQA system but.. we'll speak no further on green matters lol. I bought a mini-skid qa adapter and will be mounting it on my b219 and converting/building my attachments to that format. I already built a rock/skeleton bucket with it but since i never mounted the adapter i haven't used the bucket yet either.