Over here, I showed my SSQA conversion:

www.orangetractortalks.com

www.orangetractortalks.com

Now, if only I had forks for my tractor, I wouldn't need to do sketchy things like this:

like this:

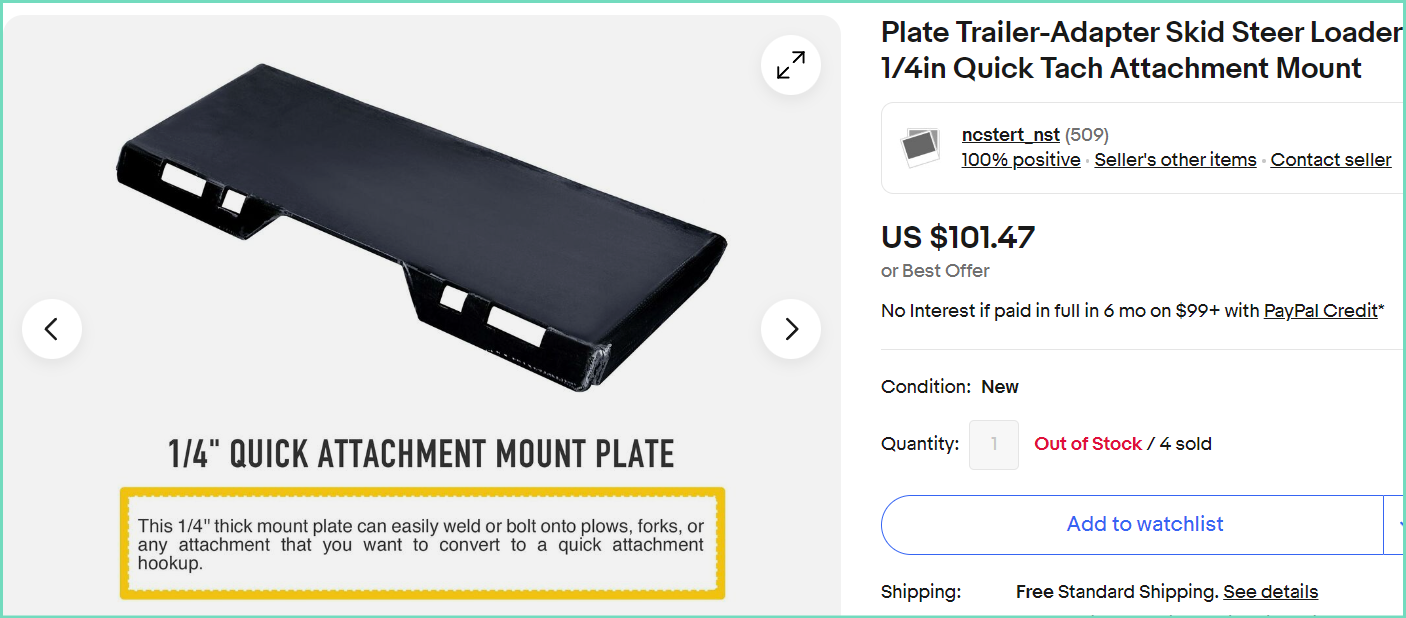

But wait, I have a welder and Mr. FedEx brought this thing the other day:

The plate is decent:

...but has a few issues. The top angle should be 45 degrees, but this one measures 37. Not sure if that matters, but it doesn't seem ideal:

...and the slots for the pins on the bottom lip are too narrow. I'll need to open them up a tad to allow the pins to be fully engaged:

So the project starts. I decided the plate had steel where it wasn't needed, and decided to cut the middle out, removing about 20 pounds of dead weight and allowing a better chance of being able to see the end of the forks from the tractor seat:

I intend to 'hang' the forks off the top lip of the SSQA plate, and decided to beef it up, by welding in a 3/8 x 1-1/4 piece in order to create a more rigid tubular structure that spans the top:

The forks themselves are started - I decided to make them out of 2x3x1/4 tubing and needing some welding practice on non-critical areas, I first put in these tapers:

(Yes - purchasing surplus/new 'real' forged forks would be safer, faster, easier, and probably about the same price. But I decided against that in order to get forks that weigh less. This is a LA302 FEL.)

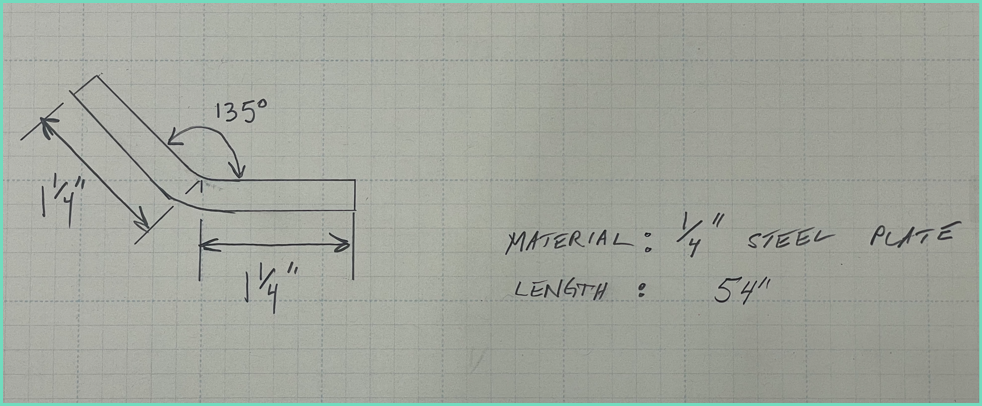

That's about it for today - I ordered one of these from the local steel supplier, and it'll be ready tomorrow:

Plus, I ran out of MIG wire. Speaking if MIG, here's today's puzzler - this probably looks familiar to experienced welders - I thought it was pretty cool:

It's just a pattern of steel filings (grinder dust) left on the concrete where the welder leads ran!

Quick Attach SSQA DIY Fabrication for B7510 LA302 FEL Bucket

Is there interest in another SSQA fabrication thread? I searched through a ton of them, and didn't see one that showed some details that are needed. I have a new (to me) LA302 on my tractor, and want to convert it to SSQA. There are several goals. First, I like to design/build projects...

Now, if only I had forks for my tractor, I wouldn't need to do sketchy things

But wait, I have a welder and Mr. FedEx brought this thing the other day:

The plate is decent:

...but has a few issues. The top angle should be 45 degrees, but this one measures 37. Not sure if that matters, but it doesn't seem ideal:

...and the slots for the pins on the bottom lip are too narrow. I'll need to open them up a tad to allow the pins to be fully engaged:

So the project starts. I decided the plate had steel where it wasn't needed, and decided to cut the middle out, removing about 20 pounds of dead weight and allowing a better chance of being able to see the end of the forks from the tractor seat:

I intend to 'hang' the forks off the top lip of the SSQA plate, and decided to beef it up, by welding in a 3/8 x 1-1/4 piece in order to create a more rigid tubular structure that spans the top:

The forks themselves are started - I decided to make them out of 2x3x1/4 tubing and needing some welding practice on non-critical areas, I first put in these tapers:

(Yes - purchasing surplus/new 'real' forged forks would be safer, faster, easier, and probably about the same price. But I decided against that in order to get forks that weigh less. This is a LA302 FEL.)

That's about it for today - I ordered one of these from the local steel supplier, and it'll be ready tomorrow:

Plus, I ran out of MIG wire. Speaking if MIG, here's today's puzzler - this probably looks familiar to experienced welders - I thought it was pretty cool:

It's just a pattern of steel filings (grinder dust) left on the concrete where the welder leads ran!