That's a Kubota-badged Woods BH650. Here is the Woods manual for their version:

Kubota sold them for use with the B9200 and a variety of L series tractors. I don't think it was ever supposed to be paired with the B7100. The 3ph mounted backhoe for the B7100 is the B4672.

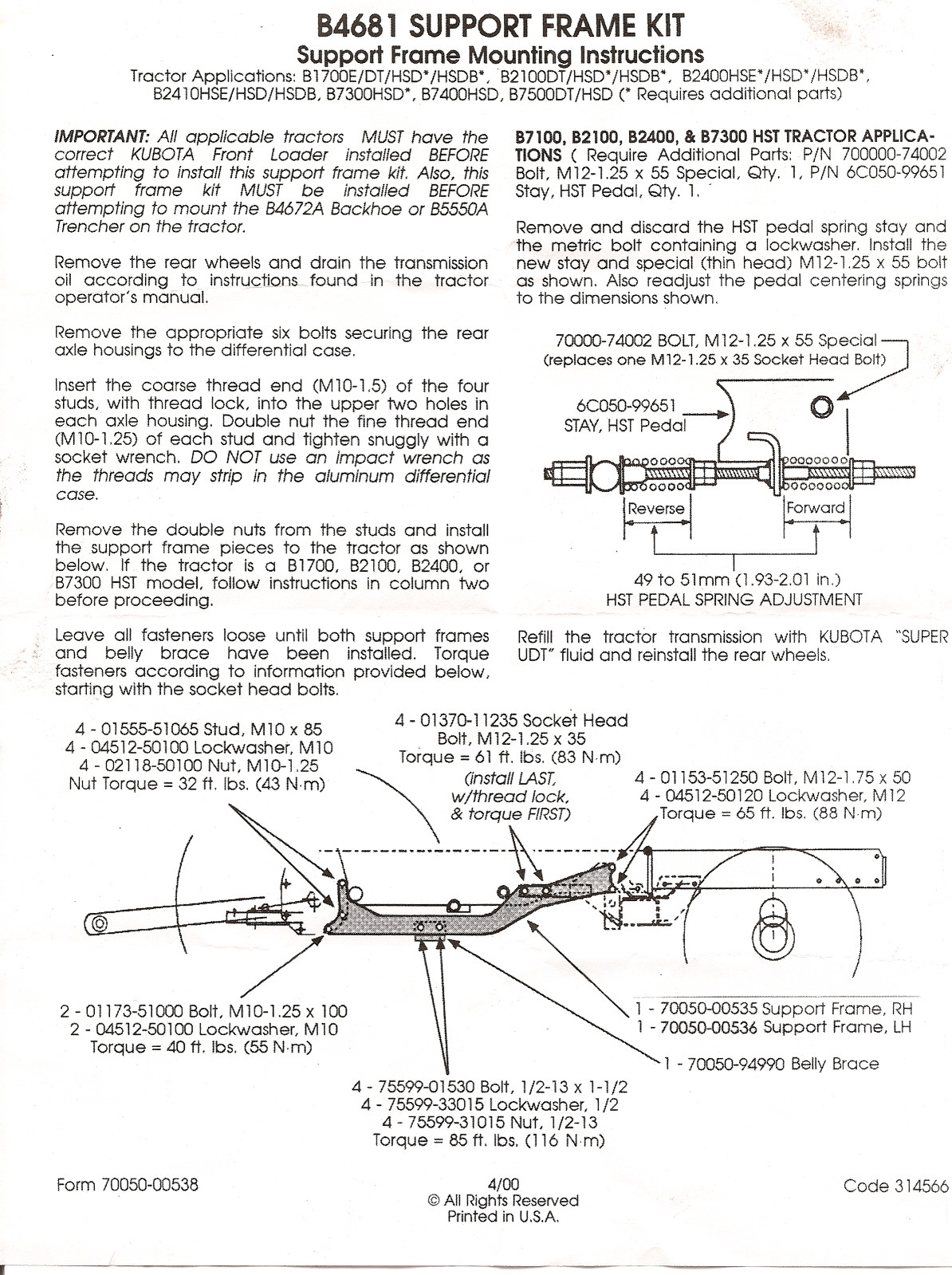

The pictures I've seen of the Kubota mounts for your backhoe do not use the 3ph lift arms. The arms are replaced with a frame to the tractor. I'm guessing they wouldn't fit the B7100, hence the mishmash of brackets holding yours on. Frankly, I don't like what I see in the pictures.

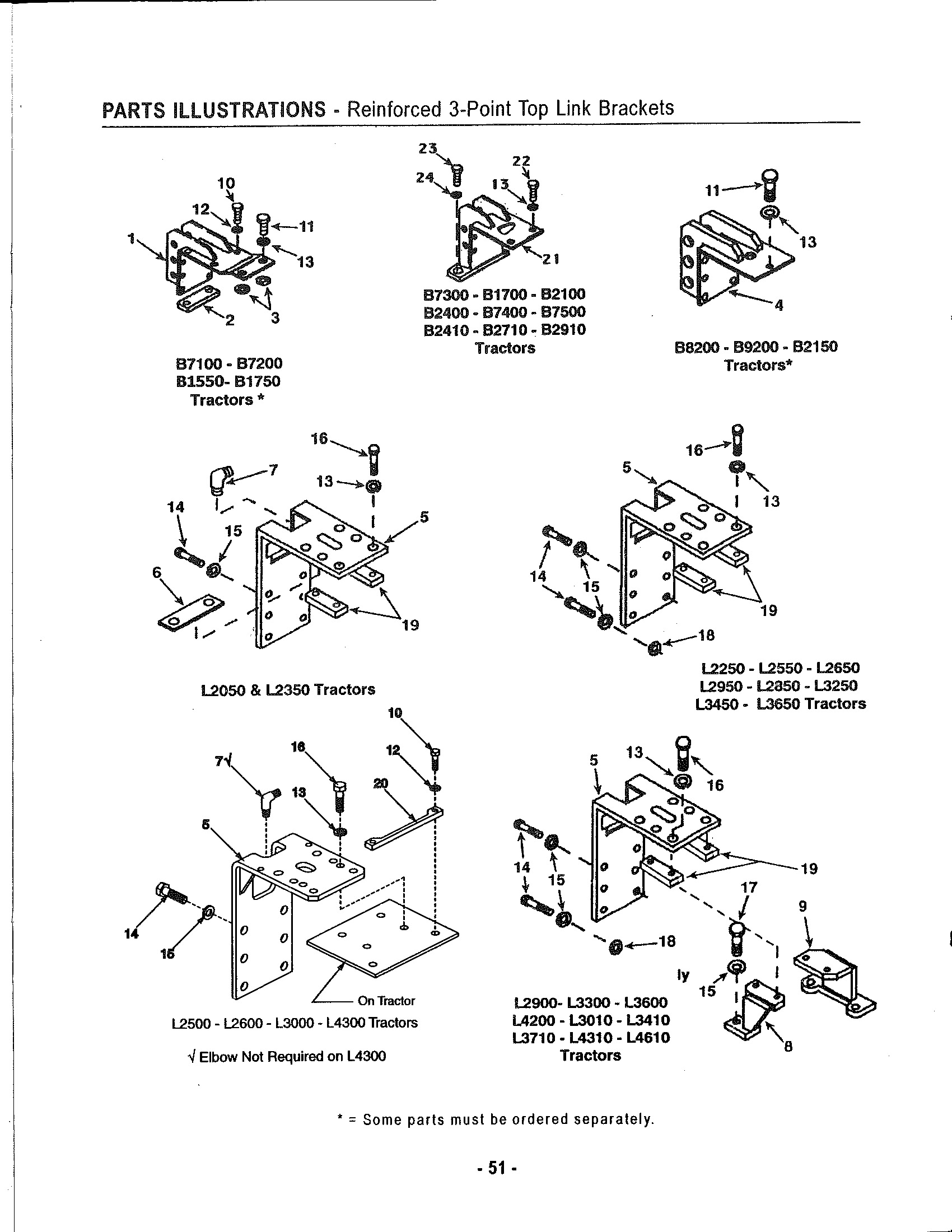

The B4672 mounting brings the backhoe closer to the rear of the tractor. The upper 3ph mounting bracket on the tractor is replaced by a heavy duty version designed to better distribute the load (pictured in Lencho's second image). From what I can see in your picture, you still have the standard bracket installed.

If you look at Lencho's 1st picture, you can see the single heavy "mast" that connects straight from the BH to the new HD upper 3ph mount using TWO mounting pins. The diagonal bracing runs between that ridgid bar and the bottom of the backhoe on either side. It is very rigid. The lower lift arms of the 3ph do not actually support any weight, they are merely used as bracing.

Your setup appears hinged on a single bolt in the middle. It appears your lower arms are used to support the weight of the backhoe. Quite frankly, I think your setup could damage the tractor's castings. I certainly would not try to use that backhoe without the heavy duty top link bracket.

If you look at page 10 in the manual listed above, you can see that those two upper pieces are supposed to overlap, forming a single straight and rigid section held rigid with bolts through two holes. The resulting mast should be pinned to the uppermost top link hole.

If possible, I would move the lower lift arms to a hole closer to the backhoe so as to bring the backhoe closer to the tractor. I think you might need to flip the pins to the inboard side of the backhoe to do so. And the diagonal bracing should be angled to a hole in the mast as close as possible to the tractor for best effect.

The HD bracket is very difficult to find these days. I made my own using 1/4" plate for the main part and 3/8" flatbar for the actual top link mount holes:

The backhoe sits low and very close to the tractor.:

Good luck!