Update - and a promise for a separate thread.

To all. I completed the operation this weekend. I removed the cam gear, installed a new one, installed the timing belt, cranked up, it ran great, and put everything back together. Drove it around and it is solid. Now for some details. Before I go any farther a BIG THANK YOU FOR YOUR HELP - EVERYONE ESPICIALLY WOLFMAN YOU HAVE BEEN KEY. THANK YOU TO ALL. No for some details.

So I'm going to create a new post to describe how to replace the water pump on one of these units because there is not much out there on how. I even called my dealer and their best mechanic told me he's sorry he could help because he has never replaced a water pump. I know my experience will help someone else who has to go through this.

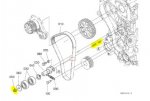

On to the removing the broken cam gear. I bought a cheap 3" gear puller on amazon. I knew it was a long shot, I've tried these things before on different tasks and they always let me down. This time was the same. Too big, jaws were wrong and cheap. It has a place but not for this job. To hedge against that I bought a 2 jaw POSI-LOCK 102. It's a 1 ton puller but most importantly the size of an iPhone 5 inches. These things are the real deal. If you need a puller check them out. I have a 8" 12 ton puller that I have used 10 times and it is a beast. These folks are a puller company and are American made and are for serous work. If you want quality and reliability check them out.

If you ever have to remove a broken cam gear on these things then you'll realize you only have 5 inches or less between the cam gear and the gas tank holder. Space is at a premium so a real tool is essential. To start the posi lock puller is about a half inch too big....PROBLEM...only if you let be. I actually took the snap ring off the puller, put it through the hole I drilled and was able to get a decent bite on the gear. Well I screwed in the cam bolt, screwed in the piston on the puller and what I found was the strength of the seize on the gear was greater than the ability of the gear to withstand the pull. In lay mans terms, when I pulled the plastic/graphite broke and the gear stayed put. I tried about 10 times, pulled almost all of the edge of the gear off and no movement. At this point I'm thinking I'm in for a long day.

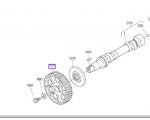

So I removed the puller and realized I had about 1/8 of the gear past the cam. At this point I gave into the idea that only heat, hammers, and penetrants were going to the leg work on this one and it had to be with some surgical precision. So for about 2 HOURS I used a drew driver on the lip of the gear and hit, sprayed, heated with a heat gun, ROTATED, THIS WAS KEY, and kept doing this. After about an hour and a half I noticed everytime I sprayed wd40 it go really rusty really quickly so I'm knew I was making progress.

At this point I decided to try the puller again. It took me 3 tries but but I was able to get a good bite finally and I knew I had a good chance. This time it moved. So I reset the puller behind the gear for a better bite and off it came. I got the gear off cleaned the area up and cleaned the rust off the cam shaft. From here I'm about 3 hours in so I slid on the new cam gear, installed the timing belt, cranked it up to make sure it sounded okay timing wise. Was good so I proceeded to put everything back together. That took about 2 hours because I replaced the alternator belt and had to tighten the belt and the bolt on the alternator was seized!! Shocker right!!

Bottom line is it's running great. I am going to post a bother thread on replacing the water pump because there is not a lot of resources out there other than a place like this and I and I know others would be lost without it. So my hope is I pay it forward. Thanks again. Let me know if this has been fun to follow and helpful. Let me know if I can help anyone here. I'll post some pics when I get to a computer in the comin days.