Well , you've already done a lot of investigation thats for sure!

The erratic spark is concerning. In the old days, the disributor weights/ springs usually would stick or something. Or a vacuum dist would have a leak. Worse thing might be worn drive gears to the dist

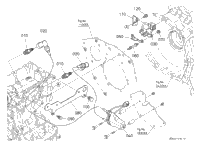

Translate to today and you've got crank position sensor and ecu telling when to fire the plugs. And other sensors for fuel mixture and such.

Is starting hard? Does it start right away when warm or cold?

You removed the charcoal canister right?

So it was running crappy when you got the machine right?

If so that kinda negates my thoughts on that change affecting it.

It would be a shame to have to pull an engine to replace a sensor. Are you sure about that?

What about wiring to each sensor. Any chafed/suspicious wires? If so maybe the sensor wires are internally corroded ( green looking wires)

The erratic spark is concerning. In the old days, the disributor weights/ springs usually would stick or something. Or a vacuum dist would have a leak. Worse thing might be worn drive gears to the dist

Translate to today and you've got crank position sensor and ecu telling when to fire the plugs. And other sensors for fuel mixture and such.

Is starting hard? Does it start right away when warm or cold?

You removed the charcoal canister right?

So it was running crappy when you got the machine right?

If so that kinda negates my thoughts on that change affecting it.

It would be a shame to have to pull an engine to replace a sensor. Are you sure about that?

What about wiring to each sensor. Any chafed/suspicious wires? If so maybe the sensor wires are internally corroded ( green looking wires)