retiree-urgency abandoned

Member

Equipment

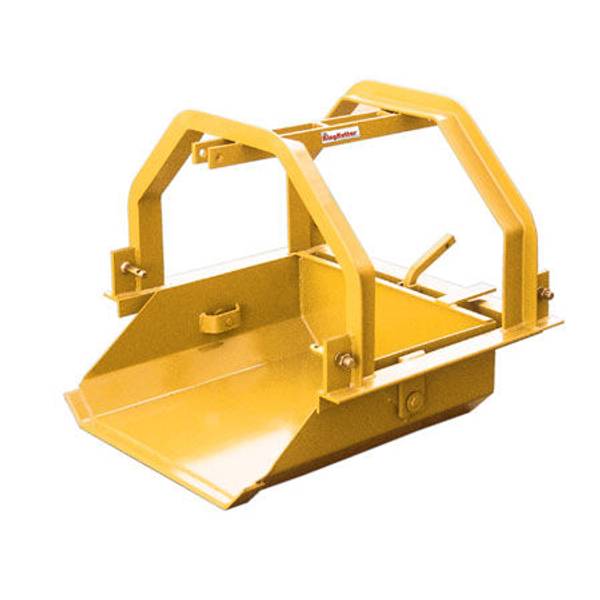

B3350, Kub. 5" rotary cutter, LP 48" forks, Titan Aerial Platform, KK XB Dump

The trees that line the drive are Siberian elms, which I love. They were planted in the early 60's by a former owner and his kids and they're pretty old, as elms go, so there's no way we wanted to take any chances with anything that might harm them in any way - the trees have outlived the folks that planted them.

Thanks for all for your suggestions - I really liked the idea of removing the center tines on a landscape rake, but I don't have one and even used ones were beyond the budget for this project.

Got back from the scrapyard with ~60 pounds of metal - 2 pieces of angle for my gravelscratcher and the rest was ornamental scrap for wife and a friend's garden decor - less than $25 for the metal - well within the budget.

Of course, I wanted to check out the piece of 4" x 6" x 5/16" angle as soon as I got home - the short-lived V 2.0 - took a couple of 6" c-clamps and clamped it to the bucket. Scratched about 6' of one ribbon, but when I put downward pressure on it, I bent both c-clamps.

But for my impatience, I should have just gone with Version 3.0 - 4 x 6 angle bolted through the bucket (four 3/8" bolts) and through 2" angle below the bucket for some extra strength. I took the angle grinder to the bottom edge of the 6 x 4 angle to give it a tapered leading edge.

Finished it up today and did a test scratch - worked just fine - was able to handle downward pressure for aggressive scratching! By adjusting bucket curl and using float or downward pressure and since I'm doing one ribbon at a time, it's pretty easy to control. I don't need that much downward pressure - front wheels nowhere near leaving the ground. I'll pick up some Grade 8 bolts of the right length when I'm in town - for now I just used what I had on hand. Photos of V 2.0 & V 3.0 below. Now to put this to work and get the drive cleaned up!

Thanks for all for your suggestions - I really liked the idea of removing the center tines on a landscape rake, but I don't have one and even used ones were beyond the budget for this project.

Got back from the scrapyard with ~60 pounds of metal - 2 pieces of angle for my gravelscratcher and the rest was ornamental scrap for wife and a friend's garden decor - less than $25 for the metal - well within the budget.

Of course, I wanted to check out the piece of 4" x 6" x 5/16" angle as soon as I got home - the short-lived V 2.0 - took a couple of 6" c-clamps and clamped it to the bucket. Scratched about 6' of one ribbon, but when I put downward pressure on it, I bent both c-clamps.

But for my impatience, I should have just gone with Version 3.0 - 4 x 6 angle bolted through the bucket (four 3/8" bolts) and through 2" angle below the bucket for some extra strength. I took the angle grinder to the bottom edge of the 6 x 4 angle to give it a tapered leading edge.

Finished it up today and did a test scratch - worked just fine - was able to handle downward pressure for aggressive scratching! By adjusting bucket curl and using float or downward pressure and since I'm doing one ribbon at a time, it's pretty easy to control. I don't need that much downward pressure - front wheels nowhere near leaving the ground. I'll pick up some Grade 8 bolts of the right length when I'm in town - for now I just used what I had on hand. Photos of V 2.0 & V 3.0 below. Now to put this to work and get the drive cleaned up!

Attachments

-

390.8 KB Views: 101

-

1.1 MB Views: 105

-

98.9 KB Views: 107

-

103.8 KB Views: 111

-

170.7 KB Views: 108