After a week of on and off activity, I have the reinforcement plates welded in place and painted.

This is after the welds were dressed. I sand blasted the side frames again getting them ready for primer.

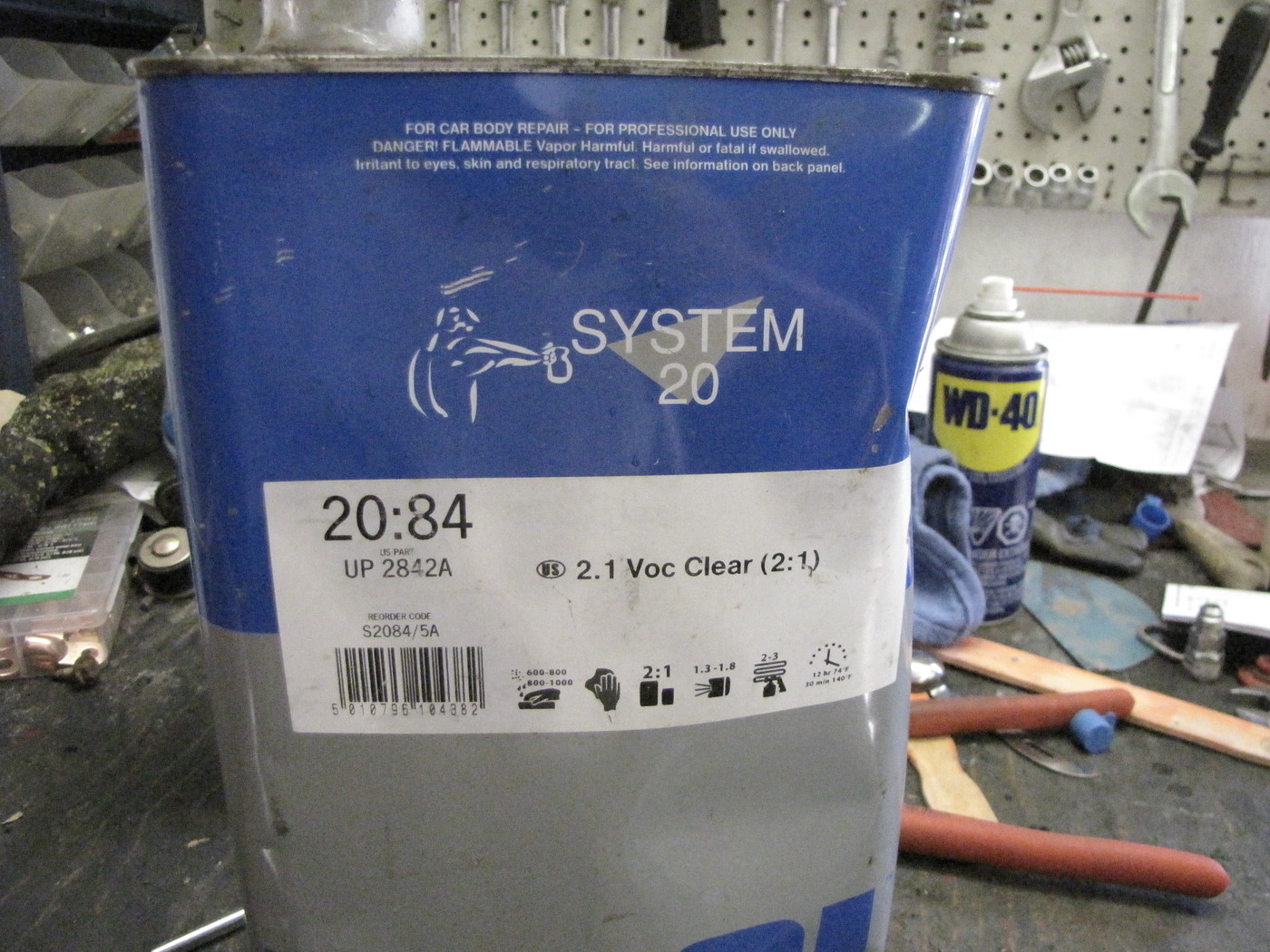

I used an automotive 2K Urethane primer.

I also tried the Harbor Freight paint system.

It's a ripoff of the 3M PPS system.

As you use the paint, the inner liner collapses. This allows you to paint at any angle, even upside down.

I had mixed the primer and it was in the gun already when the sky's opened up.

I had to spray in my garage.

The box with the filter on it (in the back ground) has a fan in it. It does a pretty good job with the over-spray.

Then the next day a little orange color.

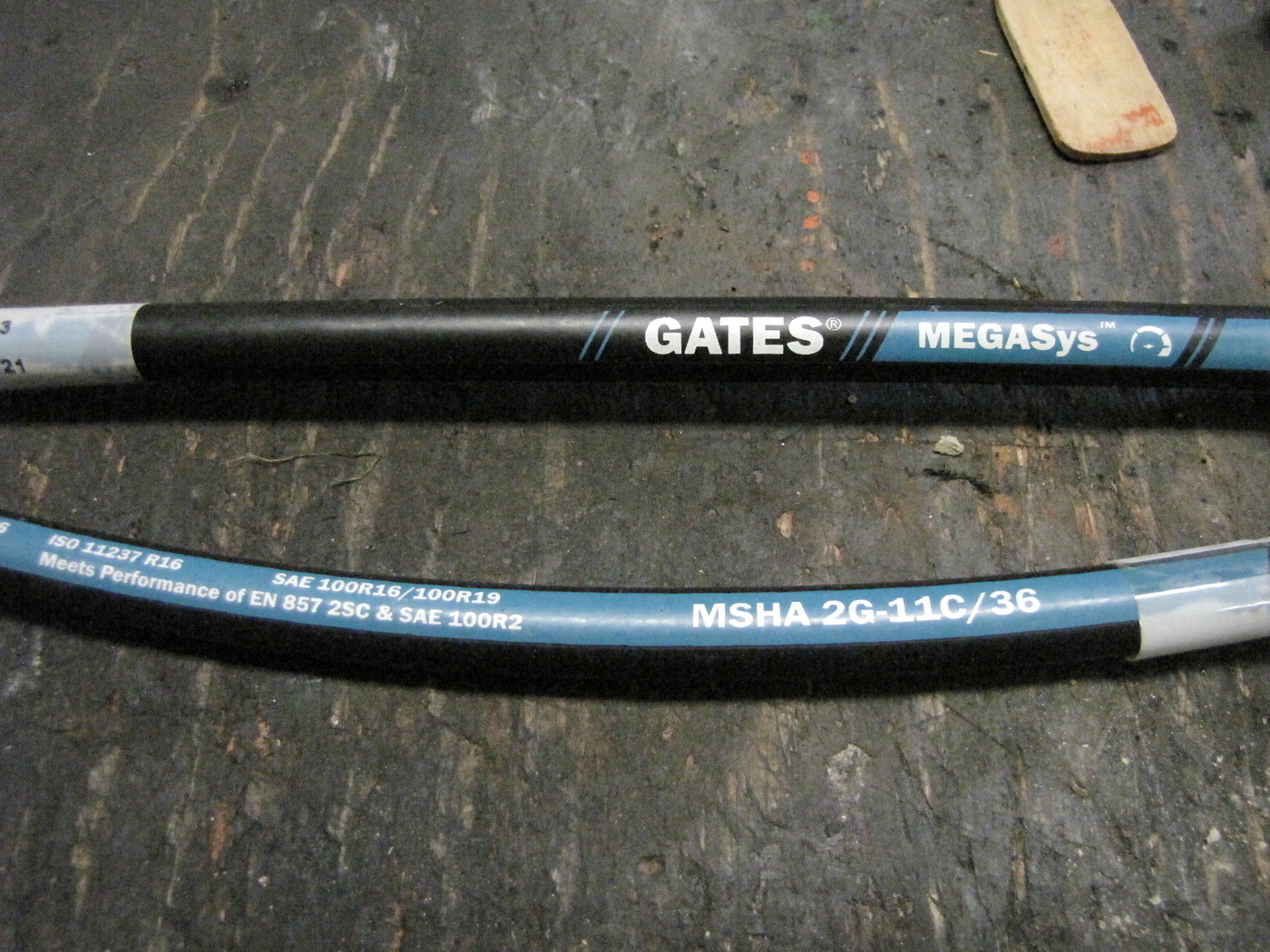

Still waiting on parts.

Hopefully by next weekend I can move on to making the mainframe.

.

This is after the welds were dressed. I sand blasted the side frames again getting them ready for primer.

I used an automotive 2K Urethane primer.

I also tried the Harbor Freight paint system.

It's a ripoff of the 3M PPS system.

As you use the paint, the inner liner collapses. This allows you to paint at any angle, even upside down.

I had mixed the primer and it was in the gun already when the sky's opened up.

I had to spray in my garage.

The box with the filter on it (in the back ground) has a fan in it. It does a pretty good job with the over-spray.

Then the next day a little orange color.

Still waiting on parts.

Hopefully by next weekend I can move on to making the mainframe.

.

Last edited: