ve9aa

Well-known member

Equipment

TG1860, BX2380 -backblade, bx2830 snowblower, fel, weight box,pallet forks,etc

Yes, I believe you are correct it's made by Radtech. When I needed a longer pto shaft I called a distributor in MA. I'm pretty sure when I gave him my model # he said something about Radtech. Even at their outrageous price for a pto shaft I would have purchased it and run up there (abt 50mi) to get it. But he couldn't even give me a date when they would have it.How many seconds from stop to stop? From the video it appears slightly faster than my earlier guestimate of 30 seconds.

BTW: Looks like the Blizzard is made by Radtech, the same people who actually make the Kubota B2789. What is the cutting width on yours?

Thanks! always appreciate a herringchoker complimentI like it ! Good job eh

After playing with a couple of power window motors, I found they just didn't have the required torque to get things moving after a hard freeze, so I built my own gear box to suit a COTS motor commonly used in robotics. I geared it down to about 150rpm, giving me a stop-to-stop time of about 10 seconds. With my particular drive and parking area, it is necessary to switch from side to side frequently, so the speed is a factor.The motor shaft turns at 45rpm. Before I ordered any motor I counted the turns on the manual crank to go 180degs. I estimated this motor would take 15-20 seconds. With my driveway almost all the max turns will be 90degs or so while plowing.

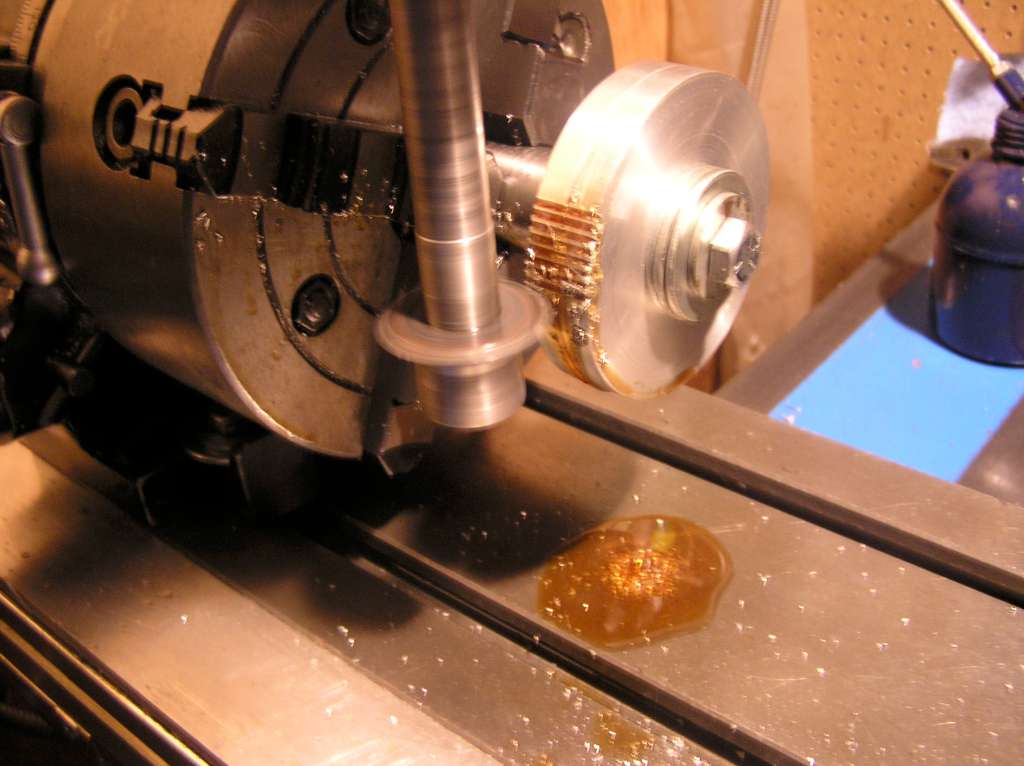

I wish I had the space for a Bridgeport or similar, but my home "machine shop" is crammed in a corner of the garage. I make do with a Chinese 3-in-1 combination machine.When I really need something machined I call one of my sons. Among his interests is a metal working shop complete with a Bridgeport (not really a Bridgeport but something equivalent).

The most important thing you need to know about hydraulics is that it is expensive to add more rear remotesIf I knew more about hydraulic motors / hydraulics I probably would have gone that route.

Yes I do have a 3rd remote at Brian's (Fitrite Hydraulics) suggestion. I would have liked to have used a hydraulic motor just for the learning experience but it's snow time here in CT and couldn't delay.I wish I had the space for a Bridgeport or similar, but my home "machine shop" is crammed in a corner of the garage. I make do with a Chinese 3-in-1 combination machine.

The most important thing you need to know about hydraulics is that it is expensive to add more rear remotes. Looks like yours are already committed to top and tilt. Even if you already have a third set on that tractor, the electric option is still probably cheaper.

One thing I would consider is coating your motor seams with a rubberized waterproofing like Plasti-Dip, Flex Seal or similar. You don't want moisture seeping in there over time.

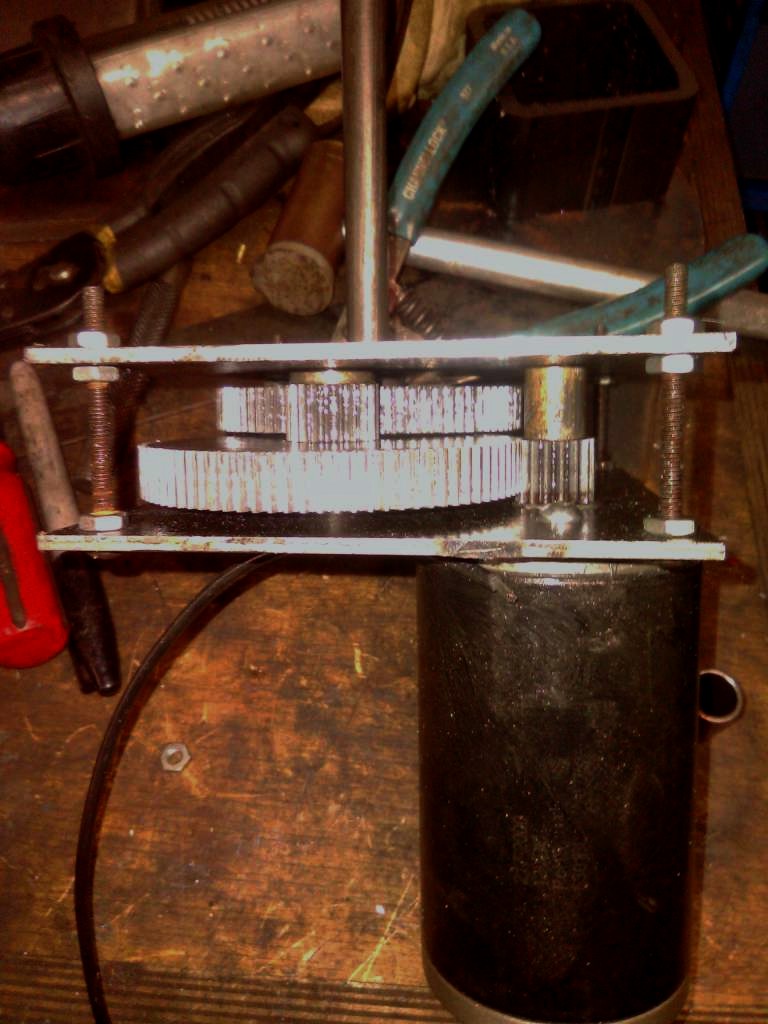

Very nice - I think we share some common interests. I will see that snowblower gearbox and raise you a solar system. Here is my dual range planetary ground speed reducer for N-series tractors - shiftable between direct drive and 3.5:1 reduction. Code name HokiePokieAfter playing with a couple of power window motors, I found they just didn't have the required torque to get things moving after a hard freeze, so I built my own gear box to suit a COTS motor commonly used in robotics. I geared it down to about 150rpm, giving me a stop-to-stop time of about 10 seconds. With my particular drive and parking area, it is necessary to switch from side to side frequently, so the speed is a factor.

In your case (making smaller adjustments less frequently) I think you will find that speed adequate. In fact, the lower speed will allow greater precision. My neighbour opted for hydraulic motors and the chute just flys around in comparison. He has more difficulty placing the discharge precisely.

I think you got a great deal on it and I have found the 51" wide Kubota-badged Radtech build quality to be excellent, so I think you will serve you well for years. (For reference, mine is now 7 seasons old, we get 12' to 18' of snow per year, my drive is 700' long with parking for over a dozen cars around the garage). Heavy gauge steel and close tolerances (particularly important is the impeller to housing clearance) make it a snow-eating monster that hurls the snow deep into the bush away from the drive.

As with any snowblower, it can be plugged if the snow is sticky enough but this one seems far less prone to plugging than many I have used over the decades. I do spray mine down with a low-friction spray called "Sno Shooter" once or twice a season, which also helps, and keep the chain drive well-oiled with chain lube (even so, it did stretch out enough to require replacement after about 6 seasons of use).

For those interested, here is my gear box project:

I cheated and paid a gear shop to make me the blanks. They did it on a gear shaper and I had them make five pieces each of the ring gear and planet carrier that also has internals in the hub for the shifter. The gears with internal splines were made from OTS broached sleeves.Oh very cool. How did you do the outer ring teeth? That would be one heck of a broach!

Thanks Torch!Don't overthink it. The deflector does not require much force. The reality is 10# force is probably overkill. Think of it this way: the clamping force of a manual adjuster or holding force of a cable adjuster is negligible, so you don't really need 200#+ of force. If you run into a situation where you need to shorten the throw of the discharged snow, you will likely pause travel for a moment while you adjust your aim anyway. Changing the throw is more likely to happen the other way -- extending it at times when precise aim is not a factor, and the stream of snow is pushing the deflector outward if anything.

Those ubiquitous Chinese linear actuators all have the same motor and trade speed for torque by gearing. 12mm/sec and a 4" throw means about 8 seconds from full down to full up. I tried that and personally prefer higher speed. After experimenting with a few different 4" and 8" versions of different speeds, my current iteration is an 8", 100# actuator that travels from end to end in about 3 seconds. But the reality is that the slower speed is only a real factor if you need it constantly. My last iteration was about 8 seconds and I left it like that for 3 or 4 seasons. It only got changed this year because the Chinesium motor imploded (internal magnets fractured and the pieces seized the motor).

Side mount or shark fin? Again, the forces just are not a real issue. Side mount offers some advantages:

1. easy to experiment. Not sure of angles and clearances? Just hold the actuator up beside the chute and mark potential mounting points with a sharpie or paint marker. Move the actuator to the opposite extreme and check the deflection angle against the marks. With the shark fin, you have limited ability to make changes if you got the math wrong. And holes to patch if you got the math really buggered up!

2. Smoother flow path. With a side-mount, the hardware is off to one side, not really interfering with discharge. A shark fin has hardware smack dead centre of the flow path. Even carriage bolts will catch packing snow. The smoother the internal surface of the discharge chute, the less likely it is to clog in borderline conditions.

There is one advantage of the shark fin: cable management. This becomes an even bigger consideration where thick, stiff hydraulic hoses are involved, which I suspect is the reason the shark fin is the preferred approach for hydraulic actuators.

But be it cable or hose, there has to be enough slack and enough room to follow the chute rotation from one end to the other. A side mount will require a longer cable at the one extreme and have more slack trying to catch on things at the other. I solved this with a small bungee cord that pulls the slack off to one side, away from other moving parts as the chute unwinds.

Have fun, and post pictures! I love seeing other people's solutions to common problems.