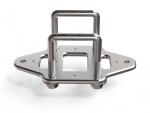

Hi all - I developed a custom bracket system for LED lights and roll bars on my other tractors out of necessity, and recently added to my L2501 earlier this year. I wanted ROPS illumination for early mornings & evenings in the woods. The mounting plates are a universal plate design adaptable for a variety of light styles, including single heads and longer light bars. Flexibility allows for multi-locations, front and back facing, and easy installation using u-bolts. I machined the aluminum parts on a CNC router using 1/4” thick material. The rearward light versions include 3D-printed adapters for improved angles to aim when digging with the backhoe or backing into the barn. I also designed and 3D-printed a compact 4-switch housing with laser cut faceplate for the weatherproof rocker switches. It is mounted under the FEL controls for a factory appearance and fit. The results thus far have worked very well.

Attachments

-

432.5 KB Views: 461

-

364.9 KB Views: 468

-

370.1 KB Views: 459

-

387.8 KB Views: 473

-

479.5 KB Views: 481

-

475 KB Views: 454