Hey guys, so I forgot to pick up a cap for the line, but I did a little test:

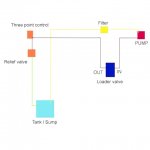

I disconnected the supply side of the fel, (uncoupled the quick coupler)no change in the 3point hitch speed.

Still slow picking up.

So I unscrewed the quick coupler off of the supply side to check for pressure, it had a good flow. I don't know if it's supposed to come out under pressure, it didn't, but it had a pretty fast flow.

Then I unscrewed the return to tank quick coupler off and started the tractor, and without moving the control valve I had about the same flow out of that hose as I did the supply.

I don't know if there's an automatic bypass built into the control valve, or if the seals are bad. But, with the supply disconnected I could manipulate the control valve to let down the boom at much faster rate. Now it wasn't nessesarily faster when I pulled it all the way to the lower boom setting, but rather when I kind of just pulled it about halfway and jiggled it around, it released at what I would consider a normal rate.

So i guess the questions are:

is the return to tank line clogged, is it sucking air, or is the control valve shot/ the wrong one?

Also, when I disconnected the return to tank coupler it still picked the boom up.