Ordering all the parts to start reassembly

Cleaned up shop, removed oven, cinder blocks, all wires off the ground, getting ready to the patch job, doing all the crankcase work, then putting block back onto tractor

Studying this area and comparing it to the diagrams, I cannot find the "crank sleeve", later I show you it labeled on the diagram, I looked through the parts, I dont remember it, but overall just studying the area to get the gaskets etc, no big deal

In this picture, the cover is on the crankcase, I do not see part 120 or where it would fit, and that seal (090) fits snug onto the crankshaft

These two pictures: bearings on the end of crankshaft,

crankshaft from engine without hole in it: bearing does not spin at all (I think this was making that noise when I was showing yall the noise from when i spun the crankshaft)

crankshaft of engine with hole in it: bearing does spin well but has slight noise

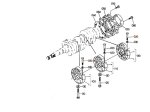

In this image, you see 110 and 120

110: the bearings I want to change, how do I remove this bearing? I can get GENUINE kubota japanese bearing for $12, I'll order 2 of those, one for each crankshaft

120: the crank sleeve that I dont have, I checked the block to see if it is on there, nope

Next chance I get, put the crankshaft up to that area and see if I do need 120 (I dont remember ever seeing it)

Here are the gaskets I am fixing to get to seal up the crankcase: 040, 60, and that rubber seal 090

Here are the main bearings, what I need:

3 orders of 220

2 orders of 230

2 orders of 240

That covers all crankcase bearings, and the thrust bearings

Summary: reread what yall said about the 3m epoxy and go get it, get main bearings, and crankcase gaskets, do not worry about steps further down the line

I did this and realized yesterday to only look at the steps in front of me

Plan: order all the parts that I just showed yall, while those parts are coming, make the patch fit better, get the 3m epoxy that yall said, and do a PROFESSIONAL diy patch job, treating it like a weld with super clean metal

(if yall want to know how to get kubota parts for 1/3 the cost of messick, let me know and I can elaborate)

Here are the exact parts I ordered, I added on the gear case gasket just to get the the free shipping

Their prices are way better than messick

Here is the gearcase of how it goes on, I did get part 100, and I know later I will need some of these o rings and whatever else

Dont move to fast, dont look to far ahead, focus on the what is in front of you...

He doesn’t seem to fire back against those who are critical of his actions.

If i fired back every time someone said something not true or misleading, wolf would KICK ME OUT INSTANTLY and never be welcome back because:

ALL i would be doing is "firing back" and not making ANY progress on the goals, meaning

If i fired back at anyone here, I would need to be removed, because the mods know that I know better than to do that, and would need be punished for being incorrect

Now: go find that 3M epoxy like someone said the metal kind, and we go back to the shop, grind down the block, fit it in better, then do the epoxy job...