Hi All,

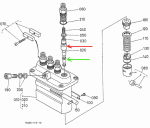

I'd recently purchased a KX161-2 excavator with the V2203-BH-5 engine and have noticed fuel leaking from the delivery valves on the injection pump. Reading through this website, it appears that the o-ring and/or copper gasket is likely the cause. After digging through the parts diagrams on Messick's / Coleman equipment, I'm not able to find the o-rings and copper gasket to reseal the delivery valves. After more research around on this site, it seems these same parts may be used in other tractor models such as the L4200 (previous thread here).

Is anyone able to confirm that the parts for the L4200 (also using the V2203) are compatible with the V2203-BH? The injection pump diagram on the thread I've referencing looks identical.

If so, it looks like o-ring #14611-51200 and delivery valve gasket #70000-65197 would be the correct part numbers to use?

And, is the torque value of 28.9 to 32.5 ft-lbs correct?

I'd recently purchased a KX161-2 excavator with the V2203-BH-5 engine and have noticed fuel leaking from the delivery valves on the injection pump. Reading through this website, it appears that the o-ring and/or copper gasket is likely the cause. After digging through the parts diagrams on Messick's / Coleman equipment, I'm not able to find the o-rings and copper gasket to reseal the delivery valves. After more research around on this site, it seems these same parts may be used in other tractor models such as the L4200 (previous thread here).

Is anyone able to confirm that the parts for the L4200 (also using the V2203) are compatible with the V2203-BH? The injection pump diagram on the thread I've referencing looks identical.

If so, it looks like o-ring #14611-51200 and delivery valve gasket #70000-65197 would be the correct part numbers to use?

And, is the torque value of 28.9 to 32.5 ft-lbs correct?