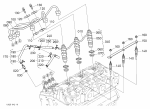

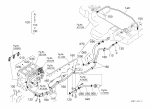

OK...further investigation results. I am finally getting an understanding of how this fuel system works...at least, in part. The tubing located at the engine left side fuel filter goes into the injection pump which then goes through the rubber tubings I replaced and into the injectors. Excess fuel is then sent back to the tank through the overflow system which exits the injectors through a rubber tubing that is near the exhaust. That tubing runs beside and below the engine, under the chasis and back to the left rear of the tractor where the fuel tank extends.

I have checked and checked to see if fuel is going through all of those tubes from the filter to the injectors, and out to the overflow tubing by the exhaust and it flows freely. My theory at this point is that perhaps that overflow tubing back to the tank is clogged somehow and is creating a diminished flow back. When it gets "full," the flow slows down and the system backs up and begins to leak at the input tubes.

There does not appear to be any hesitation, coughing or sputtering of the engine so it must be getting the fuel?

Here's the plan, if someone could validate is OK...I am going to use the compressor to blow a bit of air through the overflow tube leaving the injectors to see if the air can get back to the tank. I would take the whole tube off but it would be quite an undertaking since it runs over and around lots of other things. I see nothing that would be damaged with a bit of pressure. If there is a clog of some kind, it would go into the tank and eventually into the filters, recently replaced, so nothing lost, as I see it.

The air bleeder screw is only to bleed air from the system and there does not appear to be that problem so that idea didn't work out...but it was a good one!

I didn't put any flour/powder to check on the leak (another good idea) because I know the general vicinity which is around the tubing I just replaced and the t-connector, I just don't know why it would leak.

Thanks for listening, all. This time of year people are busy with their projects and work, so if there are no answers, I understand.

TG