Wildfire

Active member

Equipment

Kubota L5740 HSTC3 and a Kubota ZG222Z, 2013 BX25D,Custom Toyota fork lift.

Well seeing I've shown you some of the restoration work I've done I thought I'd get a little serious for a moment and show you one of the other things I do and it might spark the inventor in some of you fine folks and the ones who have made tools to post pics some of your home made working tools and please post them here so we can all get ideas and maybe be able to use them in at our own jobs.

Who knows, the tool you post just might be the tool we all have been looking for.

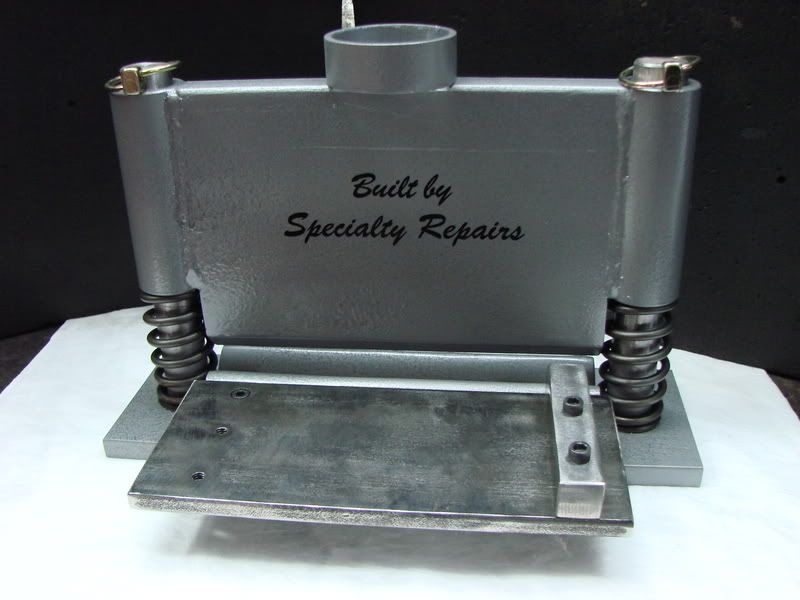

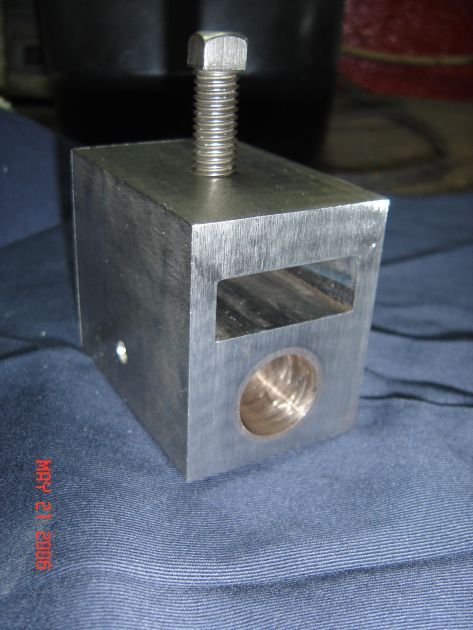

The tool I'm showing here is just one of the many I've designed and built. I started out doing some pipe work for a customer and I was having a hard time fitting the pipe together and making the perfect fit and this item does the work perfectly. I know you can buy similar things like this on the market but what's the fun of that when you can build the one you need and it if breaks you can repair it. I used this tool for years and it's perfect for my needs.

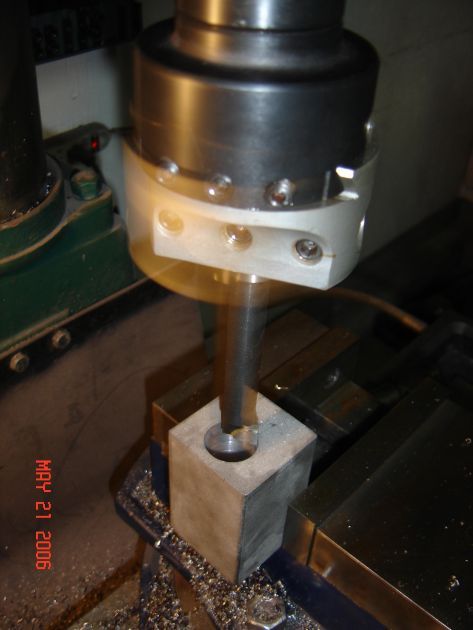

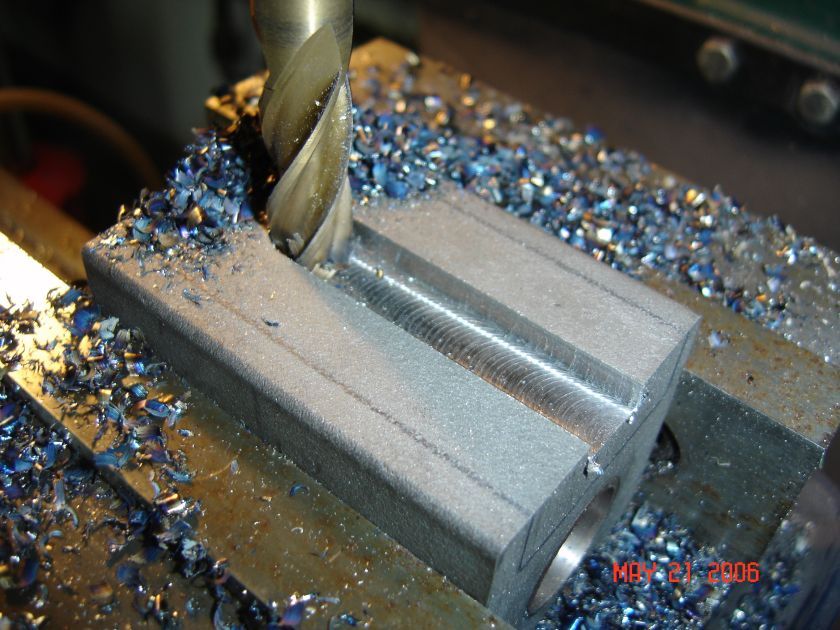

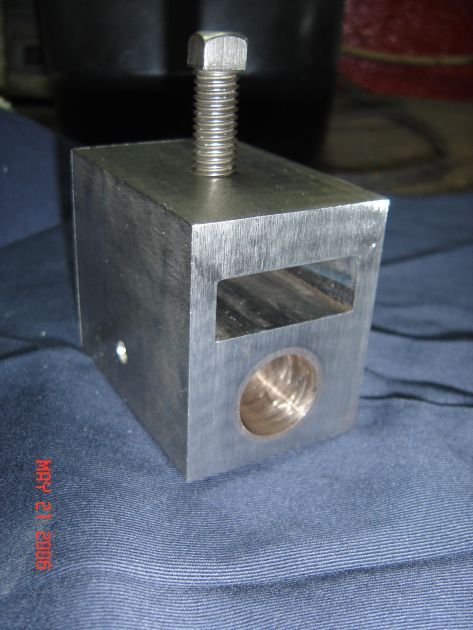

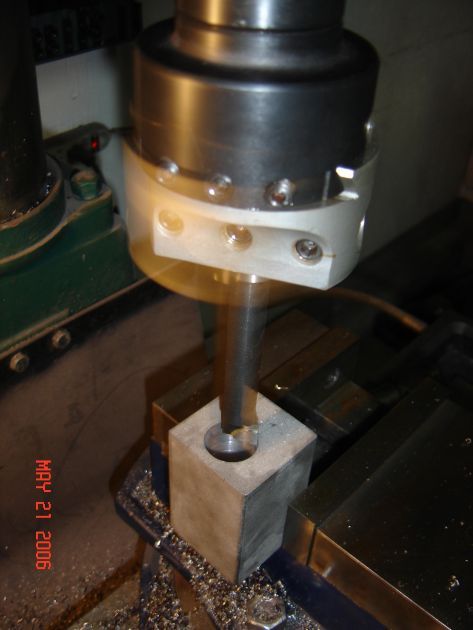

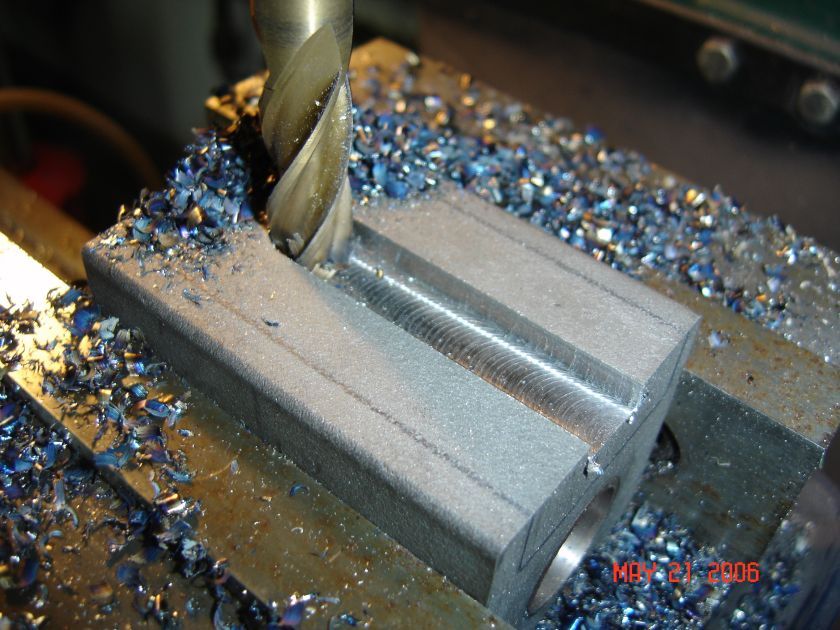

I made the tubing notcher out of small end pieces of metal I had laying around. I used an automotive strut rod for the main shaft and I use a 1/2 drill to power it as well. I milled and machined than welded all the parts. I machined the inner bushing out of oil pregnated bushing stock that is self lubricating but I also added oil service ports so I could add oil for added protection. Here's how I built my pipe notcher.

Cost of material: $0.

Time spent: 30 hours

Experience and functionality: PRICLESS!

Who knows, the tool you post just might be the tool we all have been looking for.

The tool I'm showing here is just one of the many I've designed and built. I started out doing some pipe work for a customer and I was having a hard time fitting the pipe together and making the perfect fit and this item does the work perfectly. I know you can buy similar things like this on the market but what's the fun of that when you can build the one you need and it if breaks you can repair it. I used this tool for years and it's perfect for my needs.

I made the tubing notcher out of small end pieces of metal I had laying around. I used an automotive strut rod for the main shaft and I use a 1/2 drill to power it as well. I milled and machined than welded all the parts. I machined the inner bushing out of oil pregnated bushing stock that is self lubricating but I also added oil service ports so I could add oil for added protection. Here's how I built my pipe notcher.

Cost of material: $0.

Time spent: 30 hours

Experience and functionality: PRICLESS!

![IMG_1170[1].jpg](/forums/data/attachments/0/879-0854e45f83841a520d0a4ca6db97f695.jpg)