Chill is in the air and the heating systems are starting to fire up. For me, this is the time when people are calling to have a new heating system installed. I always say to myself... "Where were you in July?"

I'm always on here asking stupid questions about my little tractor so I figured I would help out where I can and try to explain different heating systems and how they work. If anyone has any questions feel free to post them, I'll do my best to explain them. If there are any other heating pros out there feel free to chime in. My opinions are my own but have had the pleasure of working with a few excellent engineers. If anyone needs pictures to help describe how these different systems work I'll draw some up.

I'll start with the most common hydronic systems found today, the cast iron boiler with fin tube baseboard heat. These boilers are by far the most reliable heating unit ever made. They have simple construction and even simpler controls and work well with fin tube. Oil fired units need a yearly cleaning and gas fired units rarely do. Simple controls, they turn on and turn off, some may have a high fire option. The cast iron block acts as a DIRECT fired heat exchanger that your system water circulates through. Usually when the system is up to temp, the boiler will shut off but the pumps will continue to circulate water through the block and out to the fin tube until the thermostat is satisfied. Fact is you can't get anymore than 86% efficacy out of these boilers and that number is under perfect situations. Venting methods and fresh air makeup have a big effect on these numbers. If someone is telling you a higher number they are full of BS, average is around 83%.

You may also have cast iron base board or radiators (the best in my opinion) and the system works the same. The only difference is fin tube does not throw heat very well compared to cast iron. When the system shuts off, the fin tube cools in a few minutes. With cast iron baseboard or radiators the water and metal stays hot for a very long time. In most cases the temp will climb 1 or 2 deg before it starts going back down which increases the heating efficacy.

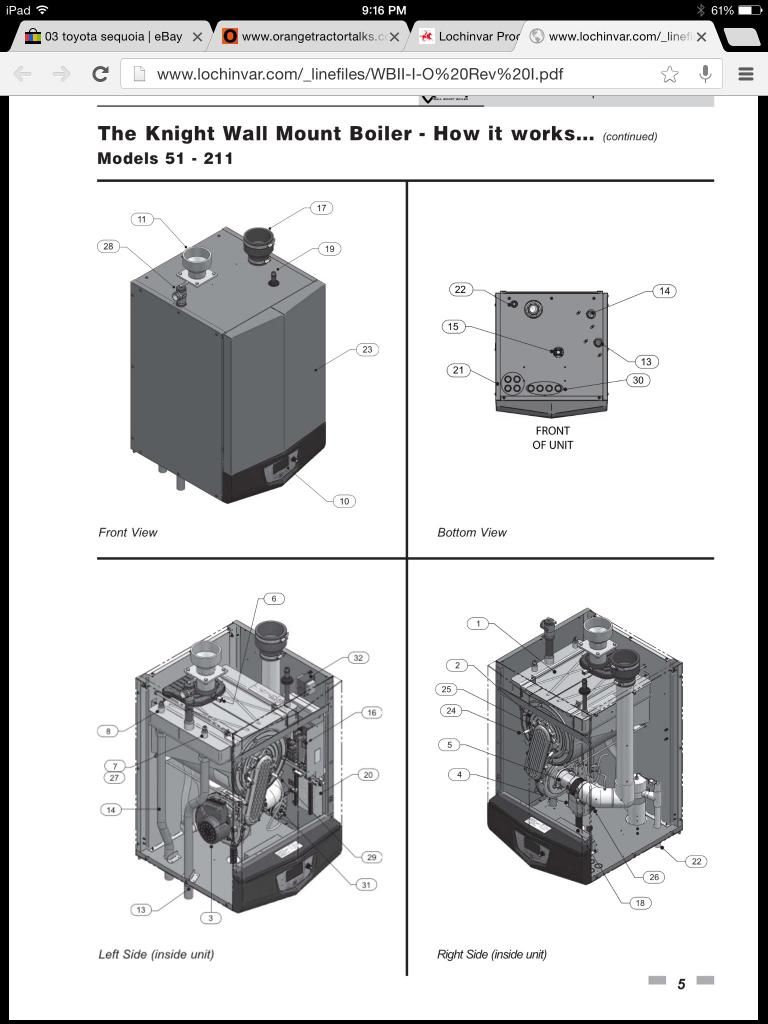

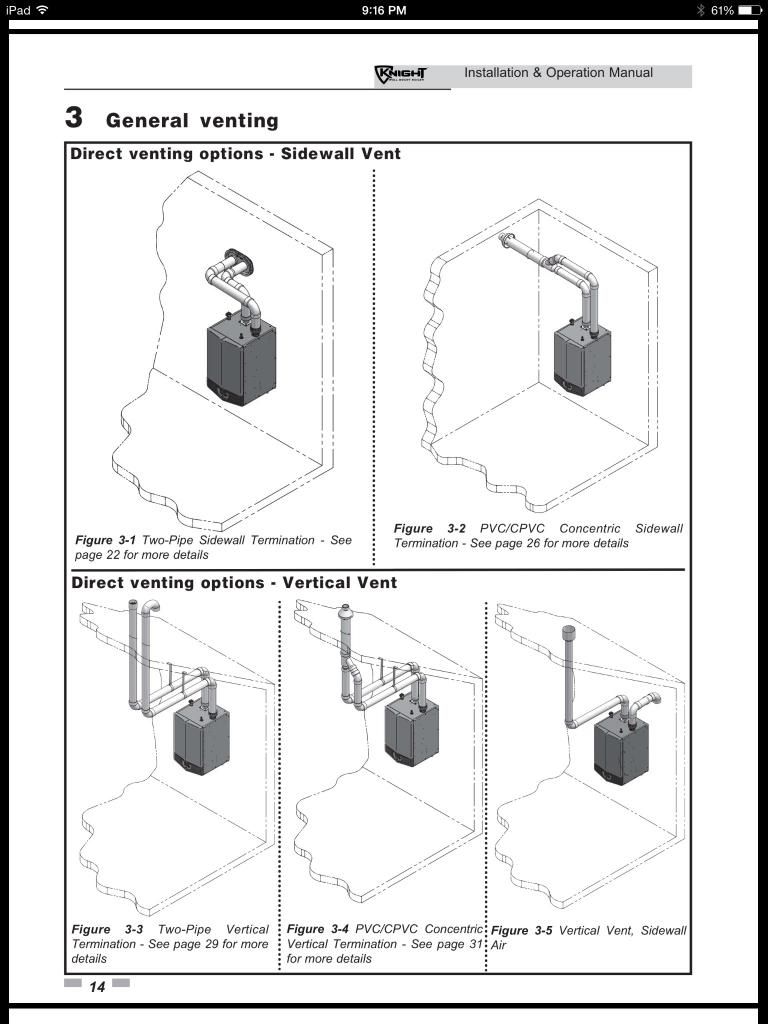

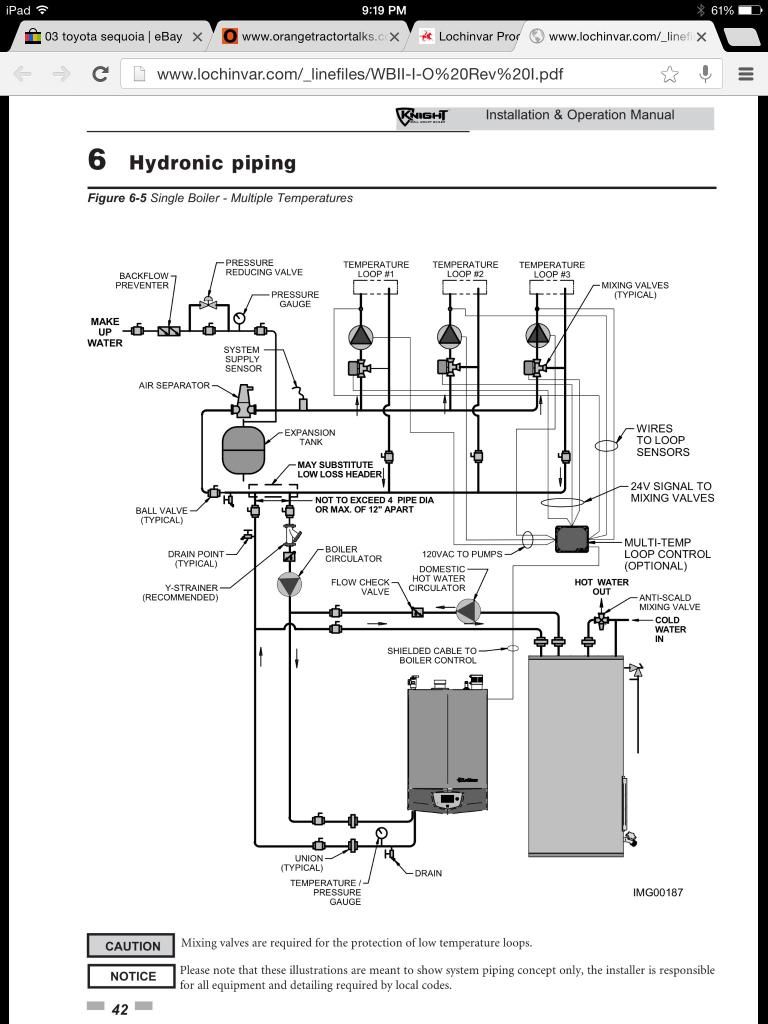

Today in our high tech world boilers have changed dramatically. They've gone from a large cast iron block to a heat exchanger half the size of a 5 gal pail that you can hang on a wall. They are computer controlled, modulate (throttle itself), read outside temps, condisate, vent with plastic pipe out a side wall, and have their own fresh air intake for combustion air. One of the biggest differences is that instead of circulating the system water through the boiler (Direct Heating), they inject the water to the system by a primary loop injection (indirect heating). The boiler has its own loop between the supply/return (primary loop) which T's into and injects into the secondary loop (your fin tube or what ever). As fancy as these things are they have had their fair share of problems over the years, most have seemed to have been worked out by now. It's kind of like the cars of today and the 60's, it's computerized.

I have a Weil McLain Ultra that is rated at 92% efficacy. That number basically represents the heat lost out of the exhaust vent. Some manufactures will advertise up to 97% but you must read the fine print. Unless you have radiant heat supplied by an indirect tank it will be more around the 92 range.

On my opinion, fin tube baseboard heat with these new boilers is practically useless. Remember, they heat indirectly compared to the old direct method and this has a big effect on how the boiler operates. The new boilers are only efficient when they have a 10 to 15 deg heat loss within your system (deltaT between supply and return temps). That is very hard to achieve with fin tube unless there is a mile of it. A low delta T will cause the boiler to rev and slow constantly or short cycle (not a good thing, puts too much premature wear on certain components).

Well this is a start.... I'll get more into Radiator Wall Panel, radiant heat, and forced hot air later on. I'll try to find some piping diagrams to help everyone understand how the primary and secondary loops work.

I'm always on here asking stupid questions about my little tractor so I figured I would help out where I can and try to explain different heating systems and how they work. If anyone has any questions feel free to post them, I'll do my best to explain them. If there are any other heating pros out there feel free to chime in. My opinions are my own but have had the pleasure of working with a few excellent engineers. If anyone needs pictures to help describe how these different systems work I'll draw some up.

I'll start with the most common hydronic systems found today, the cast iron boiler with fin tube baseboard heat. These boilers are by far the most reliable heating unit ever made. They have simple construction and even simpler controls and work well with fin tube. Oil fired units need a yearly cleaning and gas fired units rarely do. Simple controls, they turn on and turn off, some may have a high fire option. The cast iron block acts as a DIRECT fired heat exchanger that your system water circulates through. Usually when the system is up to temp, the boiler will shut off but the pumps will continue to circulate water through the block and out to the fin tube until the thermostat is satisfied. Fact is you can't get anymore than 86% efficacy out of these boilers and that number is under perfect situations. Venting methods and fresh air makeup have a big effect on these numbers. If someone is telling you a higher number they are full of BS, average is around 83%.

You may also have cast iron base board or radiators (the best in my opinion) and the system works the same. The only difference is fin tube does not throw heat very well compared to cast iron. When the system shuts off, the fin tube cools in a few minutes. With cast iron baseboard or radiators the water and metal stays hot for a very long time. In most cases the temp will climb 1 or 2 deg before it starts going back down which increases the heating efficacy.

Today in our high tech world boilers have changed dramatically. They've gone from a large cast iron block to a heat exchanger half the size of a 5 gal pail that you can hang on a wall. They are computer controlled, modulate (throttle itself), read outside temps, condisate, vent with plastic pipe out a side wall, and have their own fresh air intake for combustion air. One of the biggest differences is that instead of circulating the system water through the boiler (Direct Heating), they inject the water to the system by a primary loop injection (indirect heating). The boiler has its own loop between the supply/return (primary loop) which T's into and injects into the secondary loop (your fin tube or what ever). As fancy as these things are they have had their fair share of problems over the years, most have seemed to have been worked out by now. It's kind of like the cars of today and the 60's, it's computerized.

I have a Weil McLain Ultra that is rated at 92% efficacy. That number basically represents the heat lost out of the exhaust vent. Some manufactures will advertise up to 97% but you must read the fine print. Unless you have radiant heat supplied by an indirect tank it will be more around the 92 range.

On my opinion, fin tube baseboard heat with these new boilers is practically useless. Remember, they heat indirectly compared to the old direct method and this has a big effect on how the boiler operates. The new boilers are only efficient when they have a 10 to 15 deg heat loss within your system (deltaT between supply and return temps). That is very hard to achieve with fin tube unless there is a mile of it. A low delta T will cause the boiler to rev and slow constantly or short cycle (not a good thing, puts too much premature wear on certain components).

Well this is a start.... I'll get more into Radiator Wall Panel, radiant heat, and forced hot air later on. I'll try to find some piping diagrams to help everyone understand how the primary and secondary loops work.