The point of this post is to share my conclusion after a lot of reading and tests with the thermosyphon cooling at old Kubotas (and other tractors).

A year now i have in my hands a small beast a Kubota L1501dt similar to the L185dt.

And this beast make read and learn a lot of things, the most amazing is its cooling system and i think that i have found the right answer to everyone with a cooling system like that, a lot of old tractors have this, they working at this days,

the L210 the B6*** or the B7*** etc.

Kubota makes me think that he had measure the liquid capacity needs to cool the heat of the engine so they design the radiators bigger, to absorb the extra heat and stay within the limits at all the time.

Since those tractors don't have a temp gauge no one knows the operating temp at high load, they have a whistle and all the manuals say that if you hear it its time to stop.

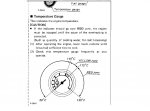

But a version of b7100 (thermosyphon) at Sweden,Finland,Denmark comes with factory installed temp gauge, the gauge is installed in the head near the injectors

photo

and this is the place that i have put mine

that temp gauge reads up to the 130C (266F) and has the normal operating temp until 110C (230F) it even has a yellow zone with five degrees celsius, so the overheating we can say that it starts about 115C (239F).

This temps are keep up with all the tests that i have read from Nebraska university for some Kubotas, they even keep up with my temps, and with some other users.

Now a small parenthesis, some users may see different temps +,-7 degrees Celsius , the think is that a lot of factors must been in mind, like, where the sensor is placed, and how is the mix of antifreeze in the radiator, more antifreeze the bigger the temp you see.

My tests are in a very good and professionally cleaned radiator with 50/50 antifreeze and distilled water, two temp sensors and a laser gun.

first sensor is in the water lines in the head, next sensor is reading the water temp at the upper hose.

And the results are.

I keep log for 3 continuous working hours in every test for some months now.

3H mowing around at full speed the maximum temp is.

Gauge at head 208F

Water gauge 197F

Laser between injectors 205F

3H with the pto hard working

Gauge at head 226F

Water gauge 214F

Laser between injectors 221F

Indicative the idle temp at the head gauge plays around 185F

Now all of this must confirmed mathematically and by Greek physics.

Our systems are pressurized with the radiator cap, as the coolant gets hot it expands creating pressure in the system. The hotter things get, the more pressure created. The radiator cap allows pressure to build up in the cooling system, pressure reduces the creation of localized hot spots within the coolant passages of the cyl block & heads which can lead to formation steam pockets and therefore air locks in a system, when it reaches its top point will vent that pressure to the overflow.

Typically each pound of pressure over atmospheric will increase the boiling point of water by 3 deg..

This means doing the math that a 13 lb. cap will add 39F deg. to the boiling point of our coolant if it was straight water ~250F. -This is at sea level-

Add now 50% antifreeze - [keeps water from freezing in the winter (by lowering the freezing point of the water) and at the same time raises the boiling point of the water.]

Remember that a 50/50 ratio of coolant has a boiling point of 223 degrees. Straight water has a boiling point of 212 degrees.

Both however are boosted significantly by the pressure in the system.

A standard 0.9 bar (13lb) cap adds ~40 degrees to the boiling point of either fluid.

So the coolant in our KUBOTA will not actually boil until ~251 degrees, or ~262 degrees if it has antifreeze mixed in.

This numbers confirmed with some post that i have read from users that have hear the whistle and have Temp Gauge

Conclusion.

With strait water we don't hear the whistle until 251 degrees F.

With 50/50 that most users run we can go up to 262F

Im not saying that i like this numbers but i don't see them also,

i see maximum under 230F at very hot (Greek) days and with continuous load even with some clogged radiator. Never above that.

So if you see under ~240F the Whistle things you are all good.

Sorry for the big post.

A year now i have in my hands a small beast a Kubota L1501dt similar to the L185dt.

And this beast make read and learn a lot of things, the most amazing is its cooling system and i think that i have found the right answer to everyone with a cooling system like that, a lot of old tractors have this, they working at this days,

the L210 the B6*** or the B7*** etc.

Kubota makes me think that he had measure the liquid capacity needs to cool the heat of the engine so they design the radiators bigger, to absorb the extra heat and stay within the limits at all the time.

Since those tractors don't have a temp gauge no one knows the operating temp at high load, they have a whistle and all the manuals say that if you hear it its time to stop.

But a version of b7100 (thermosyphon) at Sweden,Finland,Denmark comes with factory installed temp gauge, the gauge is installed in the head near the injectors

photo

and this is the place that i have put mine

that temp gauge reads up to the 130C (266F) and has the normal operating temp until 110C (230F) it even has a yellow zone with five degrees celsius, so the overheating we can say that it starts about 115C (239F).

This temps are keep up with all the tests that i have read from Nebraska university for some Kubotas, they even keep up with my temps, and with some other users.

Now a small parenthesis, some users may see different temps +,-7 degrees Celsius , the think is that a lot of factors must been in mind, like, where the sensor is placed, and how is the mix of antifreeze in the radiator, more antifreeze the bigger the temp you see.

My tests are in a very good and professionally cleaned radiator with 50/50 antifreeze and distilled water, two temp sensors and a laser gun.

first sensor is in the water lines in the head, next sensor is reading the water temp at the upper hose.

And the results are.

I keep log for 3 continuous working hours in every test for some months now.

3H mowing around at full speed the maximum temp is.

Gauge at head 208F

Water gauge 197F

Laser between injectors 205F

3H with the pto hard working

Gauge at head 226F

Water gauge 214F

Laser between injectors 221F

Indicative the idle temp at the head gauge plays around 185F

Now all of this must confirmed mathematically and by Greek physics.

Our systems are pressurized with the radiator cap, as the coolant gets hot it expands creating pressure in the system. The hotter things get, the more pressure created. The radiator cap allows pressure to build up in the cooling system, pressure reduces the creation of localized hot spots within the coolant passages of the cyl block & heads which can lead to formation steam pockets and therefore air locks in a system, when it reaches its top point will vent that pressure to the overflow.

Typically each pound of pressure over atmospheric will increase the boiling point of water by 3 deg..

This means doing the math that a 13 lb. cap will add 39F deg. to the boiling point of our coolant if it was straight water ~250F. -This is at sea level-

Add now 50% antifreeze - [keeps water from freezing in the winter (by lowering the freezing point of the water) and at the same time raises the boiling point of the water.]

Remember that a 50/50 ratio of coolant has a boiling point of 223 degrees. Straight water has a boiling point of 212 degrees.

Both however are boosted significantly by the pressure in the system.

A standard 0.9 bar (13lb) cap adds ~40 degrees to the boiling point of either fluid.

So the coolant in our KUBOTA will not actually boil until ~251 degrees, or ~262 degrees if it has antifreeze mixed in.

This numbers confirmed with some post that i have read from users that have hear the whistle and have Temp Gauge

Conclusion.

With strait water we don't hear the whistle until 251 degrees F.

With 50/50 that most users run we can go up to 262F

Im not saying that i like this numbers but i don't see them also,

i see maximum under 230F at very hot (Greek) days and with continuous load even with some clogged radiator. Never above that.

So if you see under ~240F the Whistle things you are all good.

Sorry for the big post.

Attachments

-

88.3 KB Views: 4,302

-

52.6 KB Views: 4,517

-

64.5 KB Views: 8,403

Last edited: