Hi gang! I've had my L4802 for 14 months and already have over 115 hours on it. That may not sound like alot but when you're cutting pasture a few days almost each week and lots of that in Mississippi heat, it's forever!

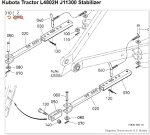

I think I have it running better than ever for my property which does have areas where it's bumpy so I adjust almost after every ride. One of the things I can't figure out is why it was delivered to me with the Joint pin on the left side in the first hole and the one on the right in the third hole (and I also realized I've been running it without the pin which either fell out or, they did not attach it before delivery last year).

Try as I might, I can't seem to get the stabilizer to move into position so that I can remove and place the Joint pin in the same spot on both sides. In reality, it's working fine so I tell myself to leave it alone but as I am a novice, I want to make sure I'm taking care of things and would like to figure out if this makes any difference at all.

My dealer has been helpful with questions in the past but this time, there has been no answer to 2 emails as I'm sure, this small dealer is busy this time of year. I'll likely have the blades sharpened in the off season and maybe a full inspection by them as well but wondered if anyone had any ideas if this pin placement is problematic.

Thanks in advance.

I think I have it running better than ever for my property which does have areas where it's bumpy so I adjust almost after every ride. One of the things I can't figure out is why it was delivered to me with the Joint pin on the left side in the first hole and the one on the right in the third hole (and I also realized I've been running it without the pin which either fell out or, they did not attach it before delivery last year).

Try as I might, I can't seem to get the stabilizer to move into position so that I can remove and place the Joint pin in the same spot on both sides. In reality, it's working fine so I tell myself to leave it alone but as I am a novice, I want to make sure I'm taking care of things and would like to figure out if this makes any difference at all.

My dealer has been helpful with questions in the past but this time, there has been no answer to 2 emails as I'm sure, this small dealer is busy this time of year. I'll likely have the blades sharpened in the off season and maybe a full inspection by them as well but wondered if anyone had any ideas if this pin placement is problematic.

Thanks in advance.

Attachments

-

103.5 KB Views: 100

-

765.4 KB Views: 97