You guys are doing some terrific projects! One of my sons is into metal work, another into woodworking. I'm into watching with my mouth open at what you all produce.

Show us your Shop and Equipment

- Thread starter Lil Foot

- Start date

Biker1mike

Well-known member

Equipment

B6200, Kubota 2030 Front Blade, King Cutter 60" finishing deck

Machinery shed getting new doors. Old double bi-folds being replaced with two sliders. Contracted out so it will be done right. Will be rough cut hemlock. There was not one part of this door that was still square. Funny feeling that the footers were less than code.

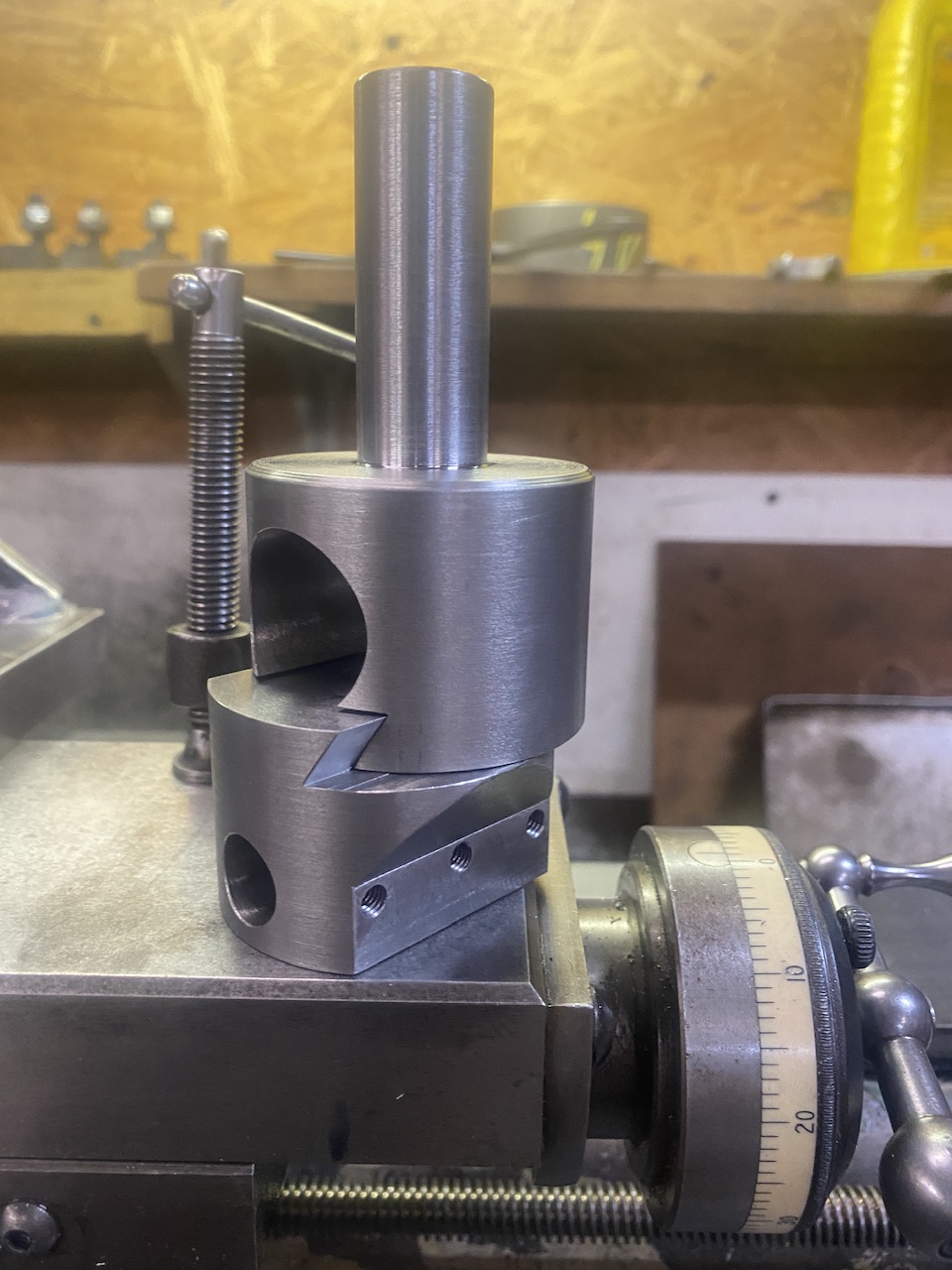

I decided to make a 2” boring head using my lathe and the milling attachment. All that’s left is to make the adjustment screw and add a saw cut and set screws to one side of the dovetail to lock down the head.

Lil Foot

Well-known member

Lifetime Member

Equipment

1979 B7100DT Gear, Nissan Hanix N150-2 Excavator

Picked up these at a garage sale within walking distance of my house, $5 ea.

Gonna need some cleanup, will post again when I get around to that.

Small one is a Shamrock Tool, 6x6x8.

Larger one is a Challenge, 8x10x6, with a King Radio asset tag from Olathe, KS.

Gonna need some cleanup, will post again when I get around to that.

Small one is a Shamrock Tool, 6x6x8.

Larger one is a Challenge, 8x10x6, with a King Radio asset tag from Olathe, KS.

Lil Foot

Well-known member

Lifetime Member

Equipment

1979 B7100DT Gear, Nissan Hanix N150-2 Excavator

Background:

When the rear hub on my B7100 failed, I found I had an oil leak from one of the bolts that hold the BH mounting plates to the sides of the differential case. When I torqued on it, it stripped.

When I get around to replacing the failed hubs, I will Helicoil that stripped hole.

The hole is a thru hole into the case, so breaking off the Helicoil tang presents a problem. (don't want that tang floating around in the diff)

So I have re-created a tool I came up with 30+ years ago when I worked for a major aerospace firm.

Situation was nearly identical, except it involved a smaller thread repair. (3/8-24 vs 12mm x 1.75)

(We tried breaking the tang with a long needle nose plier, but it was not 100% reliable for retaining the tang.)

Building this tool was a little easier to make because it was larger, but also harder because I no longer have access to an EDM machine.

Operation is pretty self explanatory; after seating the coil, tool is inserted, hooked on the tang, & the screw tightened. Tool is given a quick rap and the tang is withdrawn clamped in the tool.

When the rear hub on my B7100 failed, I found I had an oil leak from one of the bolts that hold the BH mounting plates to the sides of the differential case. When I torqued on it, it stripped.

When I get around to replacing the failed hubs, I will Helicoil that stripped hole.

The hole is a thru hole into the case, so breaking off the Helicoil tang presents a problem. (don't want that tang floating around in the diff)

So I have re-created a tool I came up with 30+ years ago when I worked for a major aerospace firm.

Situation was nearly identical, except it involved a smaller thread repair. (3/8-24 vs 12mm x 1.75)

(We tried breaking the tang with a long needle nose plier, but it was not 100% reliable for retaining the tang.)

Building this tool was a little easier to make because it was larger, but also harder because I no longer have access to an EDM machine.

Operation is pretty self explanatory; after seating the coil, tool is inserted, hooked on the tang, & the screw tightened. Tool is given a quick rap and the tang is withdrawn clamped in the tool.

I got a new to me lathe.

Had to go to Boston to pick it up.

the last picture is of back to my shop

Had to go to Boston to pick it up.

the last picture is of back to my shop

Thanks!Absolutely awesome! What kind of steel did you use?

I believe it is 1144 Stressproof based on how it machines. It wasn’t marked so it was thrown out at work and I grabbed it.

Made the adjustment screw from 4140 PHT and cut a slot and added set screws to the dovetail. The hex in the adjustment screw is the head of a 1/4” SHCS pressed in. All that’s left is adding graduations to the dial

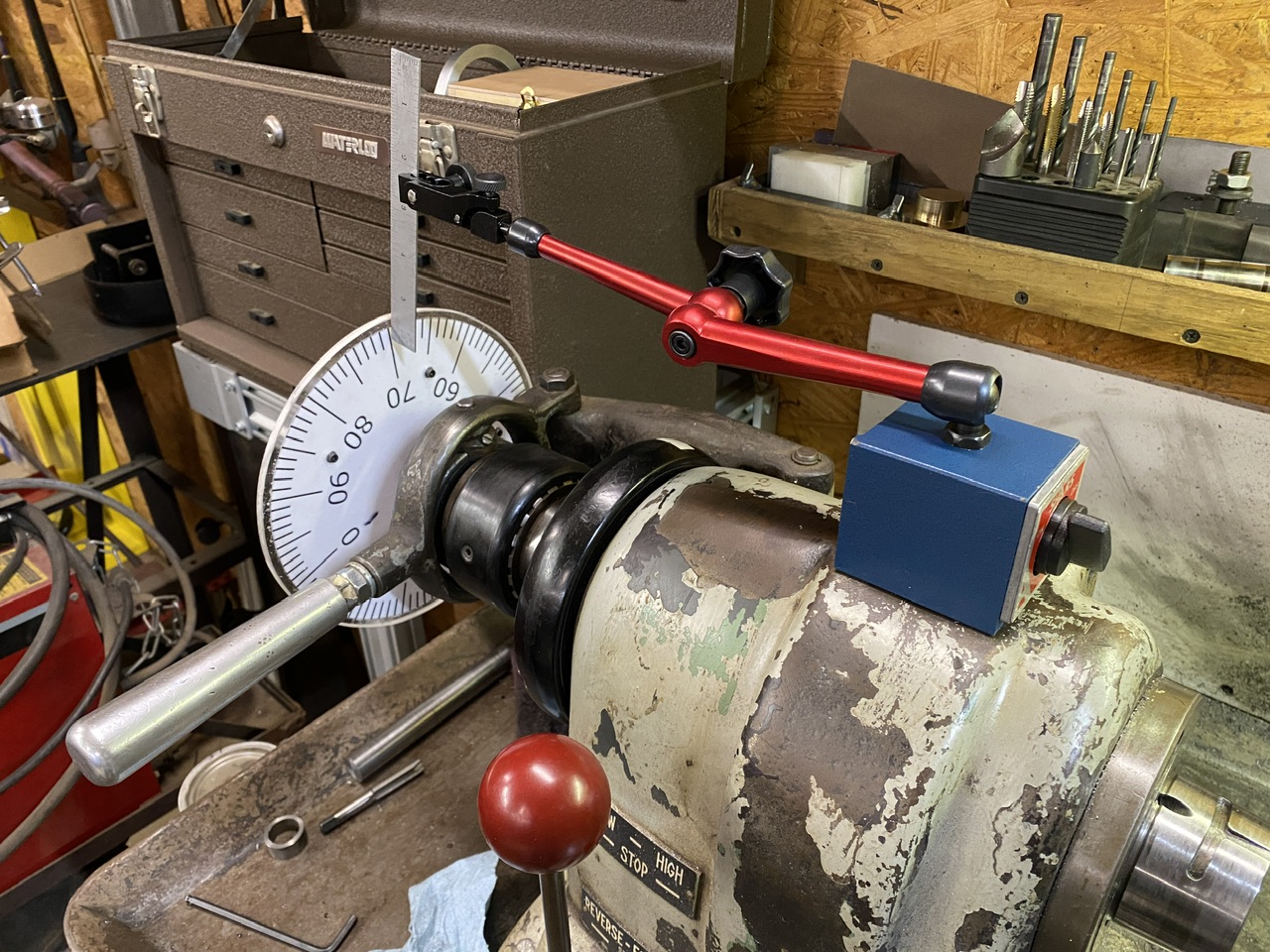

Cut the graduations on the dial today. Printed out a couple paper templates with 50 and 100 graduations and sandwiched them between 1/8” plexiglass. I bolted it to a plastic plug pressed into the spindle.

Lil Foot

Well-known member

Lifetime Member

Equipment

1979 B7100DT Gear, Nissan Hanix N150-2 Excavator

Did you lock the lathe spindle? If so, how?Cut the graduations on the dial today. Printed out a couple paper templates with 50 and 100 graduations and sandwiched them between 1/8” plexiglass. I bolted it to a plastic plug pressed into the spindle. View attachment 117286 View attachment 117287

I didn’t lock the spindle. I just held it in place by hand with the black hand wheel to the left of the headstock.Did you lock the lathe spindle? If so, how?

I will be interested to see this in action!Cut the graduations on the dial today. Printed out a couple paper templates with 50 and 100 graduations and sandwiched them between 1/8” plexiglass. I bolted it to a plastic plug pressed into the spindle. View attachment 117286 View attachment 117287

Biker1mike

Well-known member

Equipment

B6200, Kubota 2030 Front Blade, King Cutter 60" finishing deck

Sooo far above anything I could ever do !I will be interested to see this in action!

I would use a time-sert, yes more money, but a much stronger repair. I have used them in aluminum engine blocks for the heads bolts that strip out in the Northstar engines.Background:

When the rear hub on my B7100 failed, I found I had an oil leak from one of the bolts that hold the BH mounting plates to the sides of the differential case. When I torqued on it, it stripped.

When I get around to replacing the failed hubs, I will Helicoil that stripped hole.

The hole is a thru hole into the case, so breaking off the Helicoil tang presents a problem. (don't want that tang floating around in the diff)

So I have re-created a tool I came up with 30+ years ago when I worked for a major aerospace firm.

Situation was nearly identical, except it involved a smaller thread repair. (3/8-24 vs 12mm x 1.75)

(We tried breaking the tang with a long needle nose plier, but it was not 100% reliable for retaining the tang.)

Building this tool was a little easier to make because it was larger, but also harder because I no longer have access to an EDM machine.

Operation is pretty self explanatory; after seating the coil, tool is inserted, hooked on the tang, & the screw tightened. Tool is given a quick rap and the tang is withdrawn clamped in the tool.

View attachment 116653 View attachment 116654 View attachment 116655

Lil Foot

Well-known member

Lifetime Member

Equipment

1979 B7100DT Gear, Nissan Hanix N150-2 Excavator

You're probably right, but I had these h-coils on hand.I would use a time-sert, yes more money, but a much stronger repair. I have used them in aluminum engine blocks for the heads bolts that strip out in the Northstar engines.

Plus, after tens of thousands (maybe hundreds of thousands) of installations, I've never had a failure. (knock on wood)

Hello everyone my name is Mark,

While waiting for the tractor on order I figure I would contribute pics of my small shop. I can run most machines manual or CNC's and do my own programing at the control but I have never been on a tractor before..

I bought a L3902 HST with the loader & 66" bucket/ bolt on cutting edge.

For the rear I ordered Gearmore 2G2-66" scraper & 3 spool valve with spring detent kits for Top & Tilt

I have hard rocky soil against a 150ft hill. I need drainage by cutting or building up and lining with rock two 200ft canals, also I live on a privet road that gets damaged after the monsoons.

I mostly make custom gun barrels in the AK world but have been in the machining, toolmaking, manufacturing world for 40+ years and can make it if it fits on the machine.

I have a Haas CNC Lathe

Ingersall Compressor

Lagun Knee mill with new magnetic DRO and power feed.

30HP Phase converter

Jet cutoff saw

More toolboxes than I know what to do with.

While waiting for the tractor on order I figure I would contribute pics of my small shop. I can run most machines manual or CNC's and do my own programing at the control but I have never been on a tractor before..

I bought a L3902 HST with the loader & 66" bucket/ bolt on cutting edge.

For the rear I ordered Gearmore 2G2-66" scraper & 3 spool valve with spring detent kits for Top & Tilt

I have hard rocky soil against a 150ft hill. I need drainage by cutting or building up and lining with rock two 200ft canals, also I live on a privet road that gets damaged after the monsoons.

I mostly make custom gun barrels in the AK world but have been in the machining, toolmaking, manufacturing world for 40+ years and can make it if it fits on the machine.

I have a Haas CNC Lathe

Ingersall Compressor

Lagun Knee mill with new magnetic DRO and power feed.

30HP Phase converter

Jet cutoff saw

More toolboxes than I know what to do with.

After years of casually looking for a Bridgeport style knee mill, I finally bought one yesterday. It is a Willis model 1050. It was almost 5hrs away in Michigan but for the price it was worth the drive. It’s well equipped with a digital readout, power feed on the X axis, pneumatic power drawbar, oiler pump, 6” column riser, and light.

Obviously, my BX wasn’t capable of lifting the nearly 3,000 lb mill off of my trailer. Luckily, a friend around the corner has an old Massey Ferguson rough terrain forklift that I borrowed to get the mill just inside the door of my shop. My 8 ft door is too short to fit the forklift through. Then, the BX was used to slide the mill to the back corner of the shop.

Obviously, my BX wasn’t capable of lifting the nearly 3,000 lb mill off of my trailer. Luckily, a friend around the corner has an old Massey Ferguson rough terrain forklift that I borrowed to get the mill just inside the door of my shop. My 8 ft door is too short to fit the forklift through. Then, the BX was used to slide the mill to the back corner of the shop.

Last edited:

Lil Foot

Well-known member

Lifetime Member

Equipment

1979 B7100DT Gear, Nissan Hanix N150-2 Excavator

I want that old Haas!!! How muxh of the 30HP RPC does it consume?Hello everyone my name is Mark,

While waiting for the tractor on order I figure I would contribute pics of my small shop. I can run most machines manual or CNC's and do my own programing at the control but I have never been on a tractor before..

I bought a L3902 HST with the loader & 66" bucket/ bolt on cutting edge.

For the rear I ordered Gearmore 2G2-66" scraper & 3 spool valve with spring detent kits for Top & Tilt

I have hard rocky soil against a 150ft hill. I need drainage by cutting or building up and lining with rock two 200ft canals, also I live on a privet road that gets damaged after the monsoons.

I mostly make custom gun barrels in the AK world but have been in the machining, toolmaking, manufacturing world for 40+ years and can make it if it fits on the machine.

I have a Haas CNC Lathe

Ingersall Compressor

Lagun Knee mill with new magnetic DRO and power feed.

30HP Phase converter

Jet cutoff saw

More toolboxes than I know what to do with.

Dan