North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

The BX23D had a poorly designed set of ends, new ones have flats to grab it.

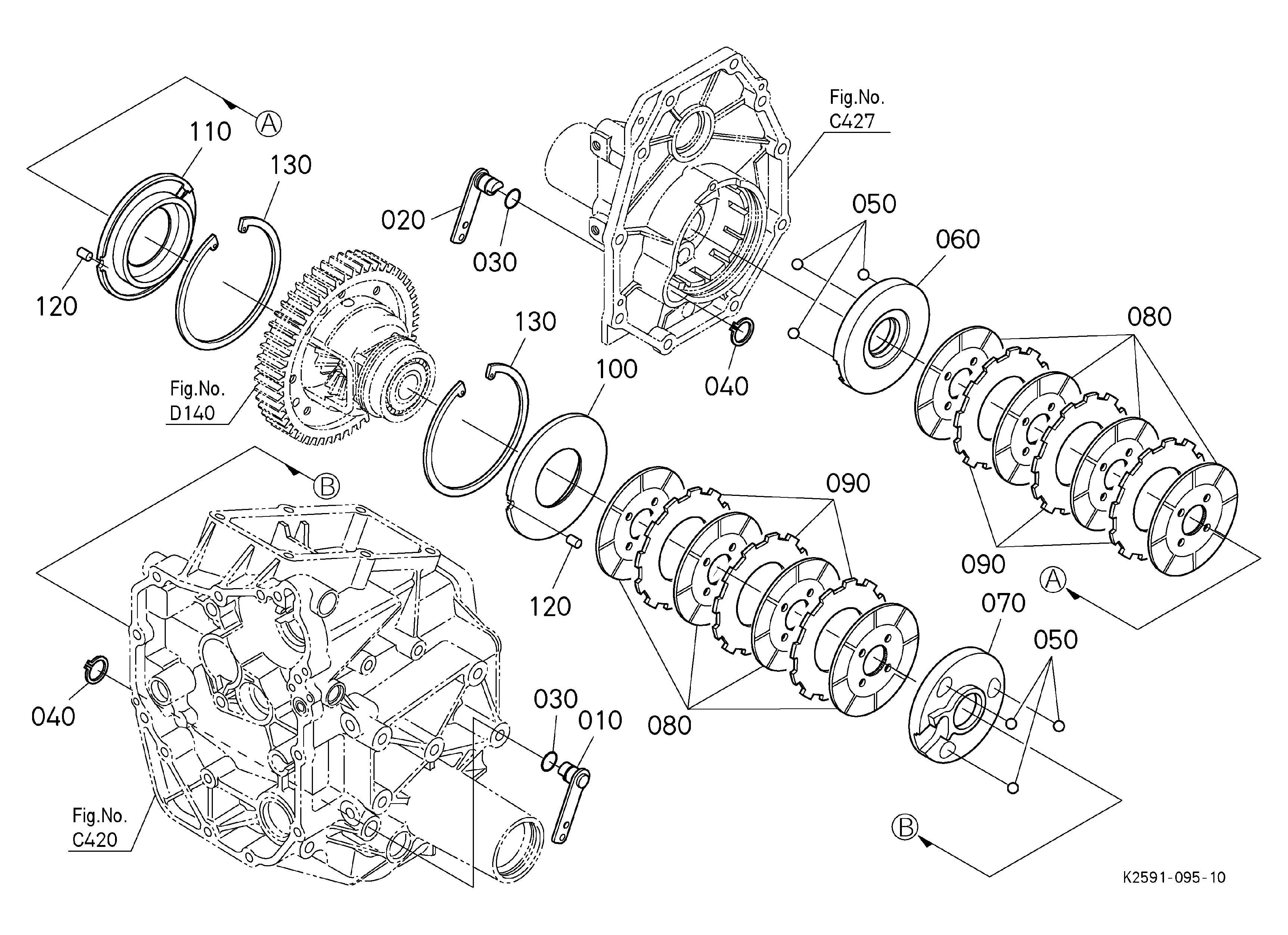

Kubota BX23D Parts Diagrams

Kubota Parts Catalog Lookup. Buy Kubota Parts Online & Save!www.messicks.com

(I don't know how to open messick's illustration to paste it here)

My tractor is a BX23D MLB The part of concern for me is part #60 in this illustration where the tie rod fastens to the steering cyclinder.

I can understand the problem in the OP with tightening (or loosening) the steering cylinder rods to the tie rods. It would take a "thin" wrench for the tie rod end plus I don't have a wrench large enough to grasp the flat spots on the steering cylinder to hold it while either the nut is being tightened or the rod is turned to tighten. The largest wrench I have is a 25mm. So, one side of my steering shows several threads because it's not tight. I'd like to correct that but how? I have vise grips that I could use on the cylinder which, because of short handles, are harder to hold while trying to tighten the nut on the tie rod end. I could probably do it if I had a skinny wrench. (Nothing skinny around here...not horses, dogs or chickens.)Any suggestions would be greatly appreciated.

Tractor Gal

Use 2 pipe wrenches one on each side and turn, don't worry about the cylinder, it will spin.

grab it wheere the purple points not the threaded ends.