Thanks Daren. I briefly looked at the brackets the big box they came in.

I noticed rather beefy brackets that appear to bolt to the bellhousing (4 bolts each) but not sure what else attaches to them or how.

I noticed two long flat stock bars about 36-42 inches long, but didn't pay attention to the attachment points.

IIRC, I saw two more long bars bigger than the other two. May have been a little shorter or longer. IDR

Today, I filled the transmission with hydraulic fluid, hooked (what I believe to be) the pressure hose (2- 2 1/2 ft long hose from distribution block with male QC) to the female QC on the distribution block (what I believe to be the power beyond connection?). I read another thread about a guy removing the FEL and not having hydraulic pressure on the 3PT and he was advised to hook power beyond hose to return, or something to that effect.

I started the tractor, and drove it out of the shop!! It did great! All 4 gears, forward and reverse, hi and low range all work great. Not sure if 4wd was working, didn't test it at all.

Bad news: Hydraulic leak at the suction line connection on the transmission. Does it have an oring or a gasket? If I take that off, all the fluid will drain out, correct?

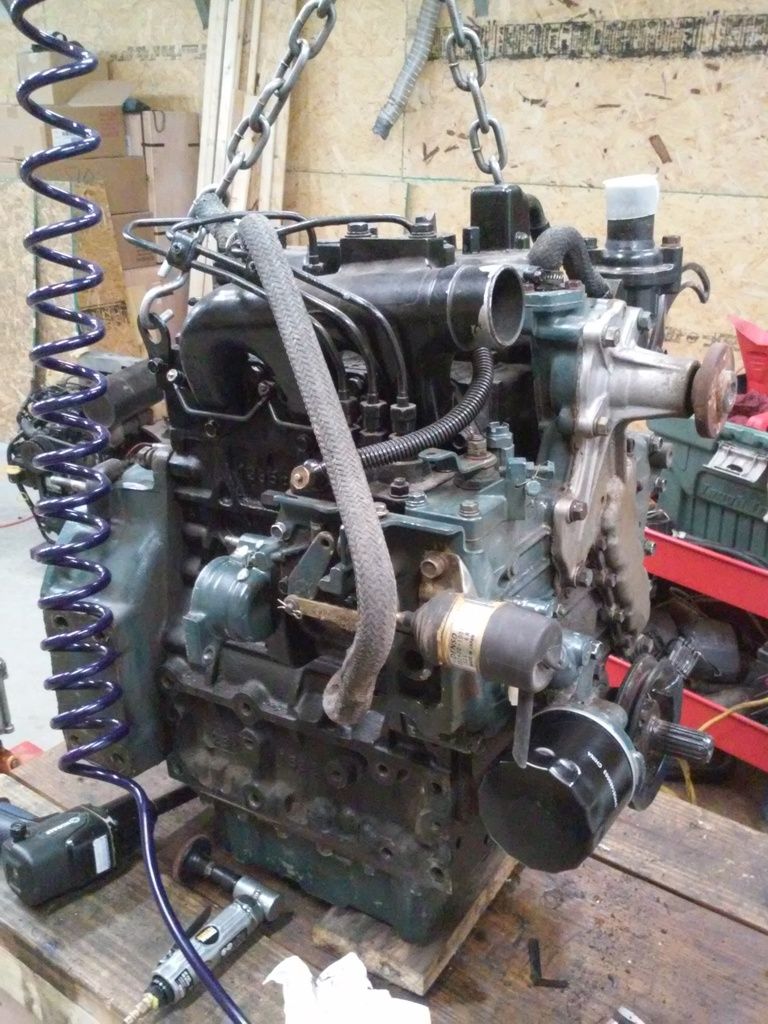

Another leak around the front of the engine. Can't see much, can't see the source. I can see drops on the front oil pan bolts (mostly the 2 or 3 on the oil filter side) and dripping on the rear of the front axle, differential housing. Oil filter isn't leaking, doesn't appear to be the front crankshaft seal. It could be the front cover gasket, or the oil pan gasket. I'll have to pull the battery and use a mirror to investigate further. There is a return hydraulic line for the power steering running in that area, but I don't think it's leaking.

If they were flogging the hell out of it, it would result in a burned up clutch, tranny, pto shaft, or implement first.

If they were flogging the hell out of it, it would result in a burned up clutch, tranny, pto shaft, or implement first.