Hi Diesel,

Hope the layoff doesn't come true.

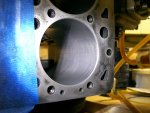

If you do decide to go through the engine, do yourself a favor and buy the proper size flex hone. You will get a much better end result.

http://www.brushresearch.com/product-line.php?line=1

Good luck,

Steve

Hope the layoff doesn't come true.

If you do decide to go through the engine, do yourself a favor and buy the proper size flex hone. You will get a much better end result.

http://www.brushresearch.com/product-line.php?line=1

Good luck,

Steve