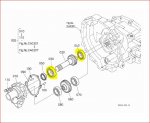

I hate to admit it but I'm stuck. I have an L3240hst. I'm replacing the engine (d1703-m-et10) and for the life of me can't find a clutch alignment tool. Does anyone have a solution? The fact that there is no pilot bearing in the crank shaft has me scratching where I don't itch.

Last edited: