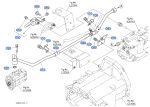

32822-33412

This part has been replaced on my

L47 three times now. Can, or has anyone ever had a metal line custom made that is stronger ( thicker sidewall I’m assuming ) to replace a week oem part?

Where the bends are in the long 4 foot metal line is where I’m getting pin hole leaks. It’s a time consuming job to get to the line for replacement, not being a tractor mechanic the job took me two full days to replace last time. I even went to a shop that makes custom rubber hydraulic lines, the 2 wire flexible line they mocked up for me didn’t have the clearance to fit in the tight quarters where the metal line goes.

This part has been replaced on my

L47 three times now. Can, or has anyone ever had a metal line custom made that is stronger ( thicker sidewall I’m assuming ) to replace a week oem part?

Where the bends are in the long 4 foot metal line is where I’m getting pin hole leaks. It’s a time consuming job to get to the line for replacement, not being a tractor mechanic the job took me two full days to replace last time. I even went to a shop that makes custom rubber hydraulic lines, the 2 wire flexible line they mocked up for me didn’t have the clearance to fit in the tight quarters where the metal line goes.

Attachments

-

512.1 KB Views: 129