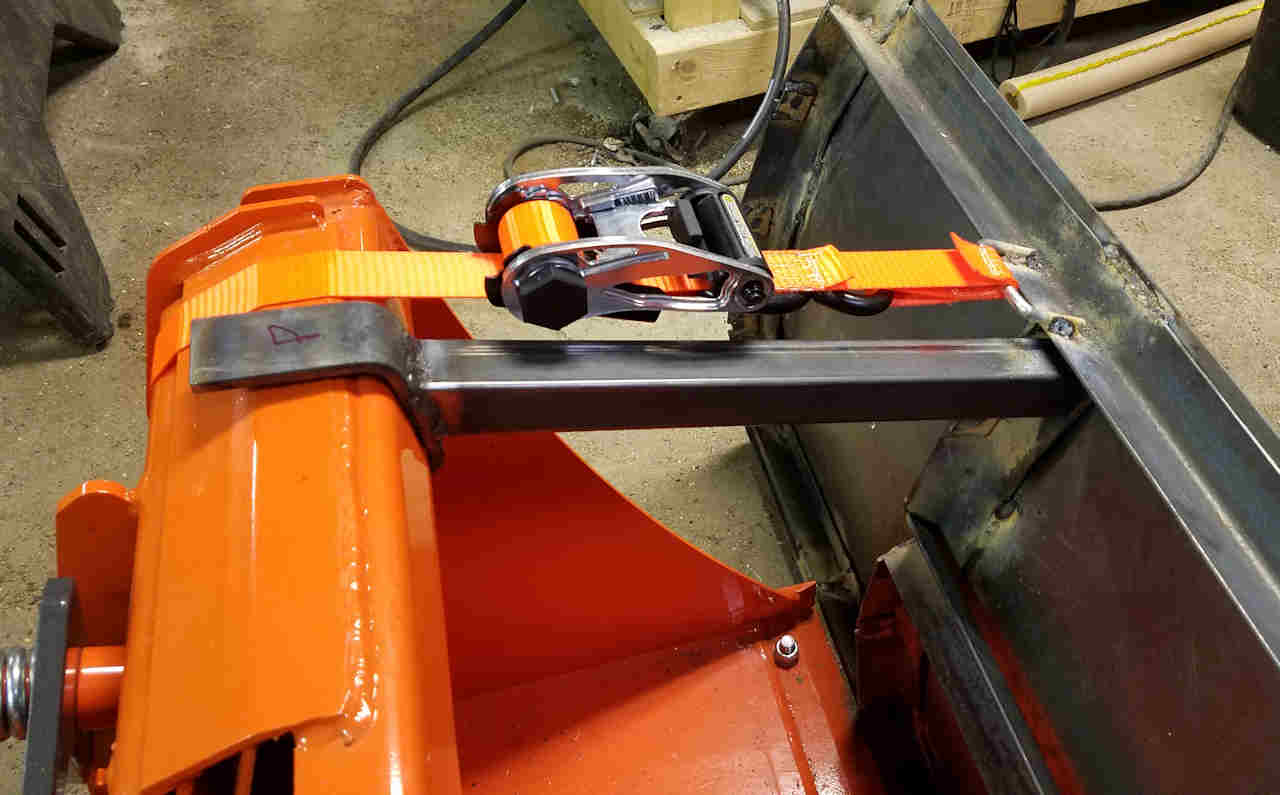

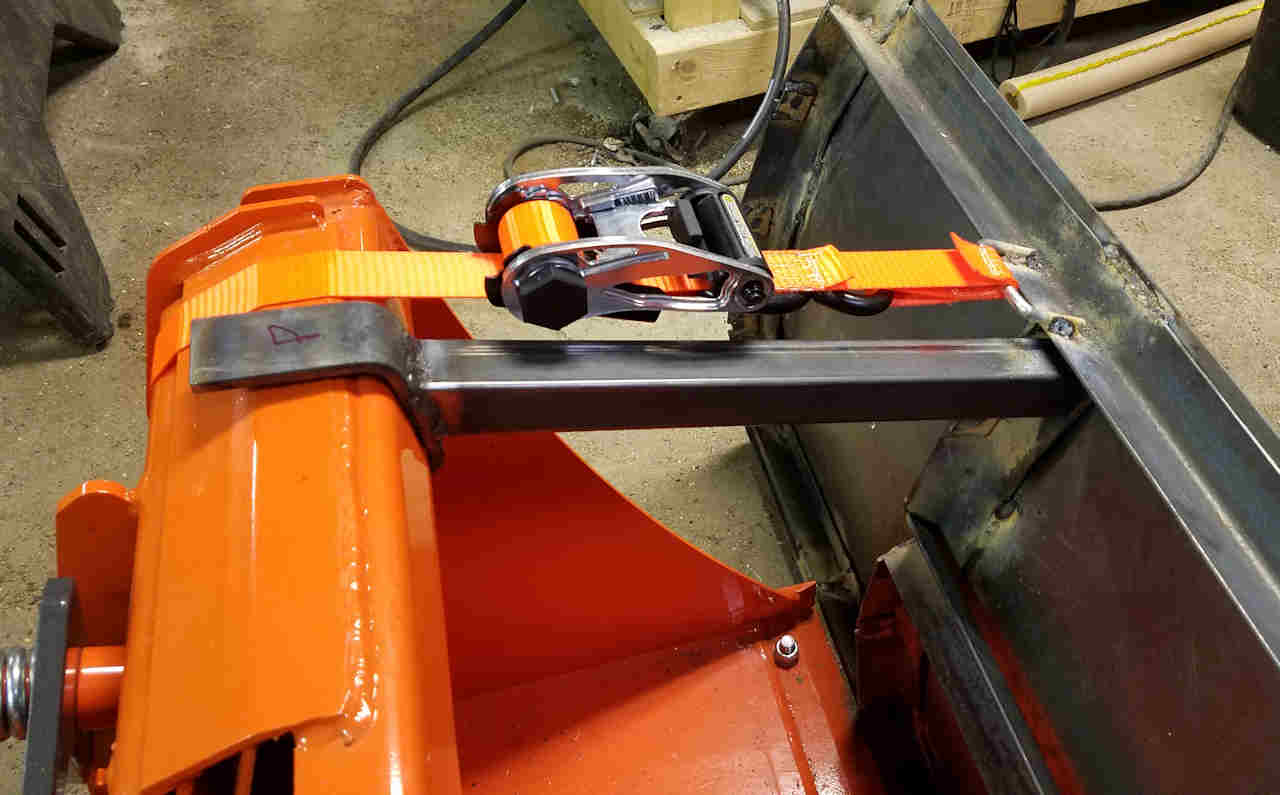

Here's a close-up of one of the upper struts. The length and angled cuts on each end more or less had to be fit ( cut, try, repeat ). The yoke that clutches the top lip of the bucket were a bitch to make, and I screwed them up. My goal was to make them large enough to line with some 1/4" felt ( from an old boot liner? ) to avoid scratching the bucket. I have no press so I spent a LOT of time heating it with the torch to bend it, and I got the bends a bit too close to each other. A made a paper cut-out the shape of the bucket lip and tried to bend to match with extra room. I failed.