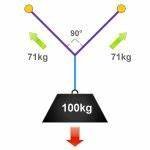

Believe it or not, I carefully evaluated using chain with two attachment points vs a single hook.I’m not an engineer but this idea of a short chain as a bridle should be carefully re-evaluated, IMO.

Using two attachment points means that the chain has double the the strength except in the hook attachment point on the chain in the center. If that center link broke, it would be similar risk as having a center hook except the rest of the attachment would likely go straight down and the chains would fall down as well.

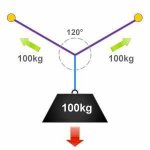

However, my tractor doesn’t have enough lifting force to break the chain that has a working limit of several times the lifting force. I think the chance of breaking the chain is neglible assuming you aren’t trying to use the smallest chain possible.

There are exactly two times the weld surfaces that a single hook would have. Half of the load is on left hook and half is on the right hook. That is an advantage of loading both hooks. If a single hook with welds could hold the load, then two hooks should certainly be able to. But, again, my tractor can’t lift enough to break the hooks off assuming my welds are good enough.

Finally, the hooks are also rated for several times my tractor lift capability. Also, half of the load is on each hook. So, the hooks may/may not be quite as strong pulling at an angle, but it’s unlikely they are going to break.

Fwiw, I’ve used it several times including yesterday, not even the paint on the hooks is damaged yet from lifting.