Good evening folks,

In a previous thread I mentioned having FEL control arm problems and a couple of posted some helpful info. It seemed that my arm didn't have enough play in the arm to raise the FEL. Using the parts diagram provided by Wolfman, I adjusted the linkage to "re-center" the control arm. It seemed to do the trick when I first started using the loader, but after an hour or so, it stopped responding at all.

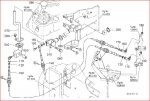

Turns out the extra play gave me enough leverage to break what I'm guessing is a bracket that attaches to the control valve (the part right under the nut labeled # 130 in the attached diagram). I've also included a picture of the broken bracket. The tractor is almost 5 years old, but has not been used much, it only has 65 hours on it.

What would cause enough resistance in the control valve to make that part break and any tips on fixing it?

Thanks!

In a previous thread I mentioned having FEL control arm problems and a couple of posted some helpful info. It seemed that my arm didn't have enough play in the arm to raise the FEL. Using the parts diagram provided by Wolfman, I adjusted the linkage to "re-center" the control arm. It seemed to do the trick when I first started using the loader, but after an hour or so, it stopped responding at all.

Turns out the extra play gave me enough leverage to break what I'm guessing is a bracket that attaches to the control valve (the part right under the nut labeled # 130 in the attached diagram). I've also included a picture of the broken bracket. The tractor is almost 5 years old, but has not been used much, it only has 65 hours on it.

What would cause enough resistance in the control valve to make that part break and any tips on fixing it?

Thanks!

Attachments

-

81.9 KB Views: 300

-

19.1 KB Views: 301