Greetings all, I need some help. I have started the process of splitting the tractor for clutch replacement, I'm at a standstill. I can't remove the shuttle shift rod off of the transmission. It took me a bit to remove the dual roll pins, got them out with some patience. I am thinking it's just splined? I have been soaking it for a while, no luck, any advice? Thanks

L2900 splitting the tractor

- Thread starter Riverbanks

- Start date

I should also mention, I have the factory service manual, it doesn't include anything for my situation, but, if any one needs info. for their tractor, let me know

rbargeron

Well-known member

Lifetime Member

Equipment

L5450, L48, L3250, L345 never enough attachments

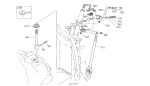

170 and 190 in the picture are the dual roll pins, they are out, still no release, also in the picture it shows the bolt still in place, that's holding the shaft in place coming out of the transmission, in the manual next picture it shows that shaft is welded to a fork in the tranny, so I think that shaft is only removable from the inside? The other possibility is the picture is separating the shafts right below the u joint, but there is no roll pins. I do see a bit of splines on the bottom of that?

I should have started out by saying, thanks for your time. I removed the hold down bolt and tried pulling up on the shaft, it came up a 1/4" and stopped. That's when I looked at tranny picture and the fork is stopping it. At that same time I could move the lever back and forth with no resistance, I was out of the notch for shuttle shift in the tranny. I lowered it back into position and installed the bolt again, does this sound right? I am trying everything I can, carefully. I also used a screwdriver for a wedge on top of the hold down and shuttle shift arm to try and ease it off with plenty of lube sprayed in the rollpin hole, nothing moves

Another thought was heat, but the fuse box is right above it, will I get into more trouble? Per procedure, I have the steering column assembly raised as far as it will go, it's stopping on the u joint on shuttle shifter, it had to be raised to access the dual roll pins., The other problem with heat, will I hurt the seal on the shaft coming out of the tranny, argh

rbargeron

Well-known member

Lifetime Member

Equipment

L5450, L48, L3250, L345 never enough attachments

I shouldn't have just guessed at it based on old experience with machines.

In the Separation sections of your manual does it say the shuttle parts have to come out for the trans & clutch housing to move away from the engine? It would seem the lever & shaft want to disconnect to stay with the front section, but splitting at the engine should not involve those parts? Which seam are you trying to split it at?I should also mention, I have the factory service manual, it doesn't include anything for my situation, but, if any one needs info. for their tractor, let me know

Last edited:

Good point, there are two ways to do this, one is, disconnect the shuttle shift assembly and leave the steering hoses attached to the wheel, let the assembly stay with the front half, there is plenty of hose movement to do so, two is, disconnect steering hydraulic hoses to remove remove entire assembly, both require shuttle shift removal, now, in your post, you said (wsm) I have (fsm) from messicks, any difference? I will say that what I got with the grainy black and white pictures is a bummer

I am splitting the trans to engine seam, am I correct on that? I do see the second seam, but the access to clutch is in the forward seam

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

You're splitting it here right?

There are 2 ways to separate the shuttle shaft, lower in yellow is not splined smooth shaft.

connections in red are splined, put a alinement mark on the shaft and the joint if you are separating it here.

If you lift the column and use a hammer to tap up on the joint one of the connections will come loose.

There are 2 ways to separate the shuttle shaft, lower in yellow is not splined smooth shaft.

connections in red are splined, put a alinement mark on the shaft and the joint if you are separating it here.

If you lift the column and use a hammer to tap up on the joint one of the connections will come loose.

Rereading the wsm, it states, remove the shuttle shaft lever, then remove panel frame assembly, totally backwards, lol, the frame assembly shrouds the dual roll pins, they are parallel to the tractor with no access hole, so remove the frame assembly screws and raise it a few inches to get a clear sight and use of a drift to remove the roll pins

Yes, you are correct on the seam, my bad, living and learning, lol, back to the removal of shuttle shaft, I have tapped on the upper joint as best as possible, not much room for a swing of the hammer, I have tried to pry up on the lower joint as well, no luck on either

Thanks to all, I now know that I was close in my approach, you guys have confirmed it, I got a rusty old "babe", it will separate with patience and oil. I told my friend over a year ago to fluidfilm this thing, na, nothing

Update, had friend(owner) come over, with no progress on separation, we cut the lower shaft with a sawzall, he found a used part for 20$, it will be a lot easier to remove the lower piece with the tractor separated, bash me if you want, I felt like a hack doing so, lol, thanks again to all, I'll stick around. I have a t1400 rider from 92', and a 6500av generator from 03', probably will ask for assistance at some time

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

Sometimes we just gotta do what we gotta do!Update, had friend(owner) come over, with no progress on separation, we cut the lower shaft with a sawzall, he found a used part for 20$, it will be a lot easier to remove the lower piece with the tractor separated, bash me if you want, I felt like a hack doing so, lol, thanks again to all, I'll stick around. I have a t1400 rider from 92', and a 6500av generator from 03', probably will ask for assistance at some time

Save the parts so you can match up the clocking of the shaft or it won't shuttle.

had one stuck, heated it and it came free. Other one, had to remove the upper part from the lower (spline) which is a pain in the butt. Once the pedestal is off everything is right there and a whole lot easier to get at.

Thanks for the reply, I was starting to doubt my abilities, I was gonna give up and go back to selling oranges on the side of the road, lol. I do have another question, can I get a aftermarket clutch or should I stay with oem?

rbargeron

Well-known member

Lifetime Member

Equipment

L5450, L48, L3250, L345 never enough attachments

I use aftermarket clutch disks like this. They work just fine, last a long time (haven't ever replaced one) and the price is pretty good.

Good to know, thanks, sometimes saving a buck comes with compromises, at this point, I, we are not sure of the failure, two years ago I replaced the front axle seals for it, the owner let me spread a load of gravel before he took it, at the end of the load, the clutch was not disengaging completely, not horrible but a little resistance changing gears, let it cool off, back to normal, now fast forward, the clutch pedal assembly is binding, well not pedal, the rod that holds the throw out bearing. Got bad enough he broke the gear shift lever twice, now I get it back