I've got a problem engaging the PTO. It's always been notchy, but this year after not using the PTO for at least 1/2 a year, it would not engage the PTO. I tried to shift and it would just grind. I was at idle RPM. Last week when I wanted to connect the shredder, I had to engage the PTO with the engine off and then start it up. After shredding, I tried to engage the PTO while it was running and it went in as it used to. I thought that running it had freed up whatever was sticking and all was good.

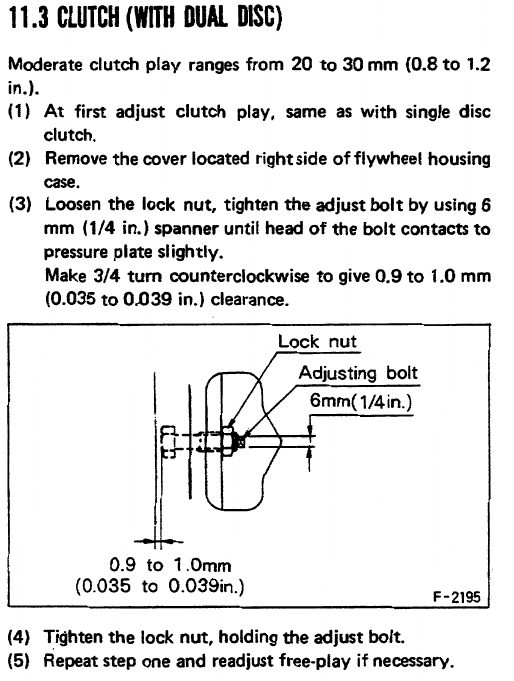

Not so. Today I had the auger hooked up and while it did engage the 1st time, the 2nd time I tried it would just grind again. So I parked it and looked to adjust the clutch. Mine has the dual disk/stage clutch, so there is the pedal free-play adjustment and then another adjustment described in the manual,

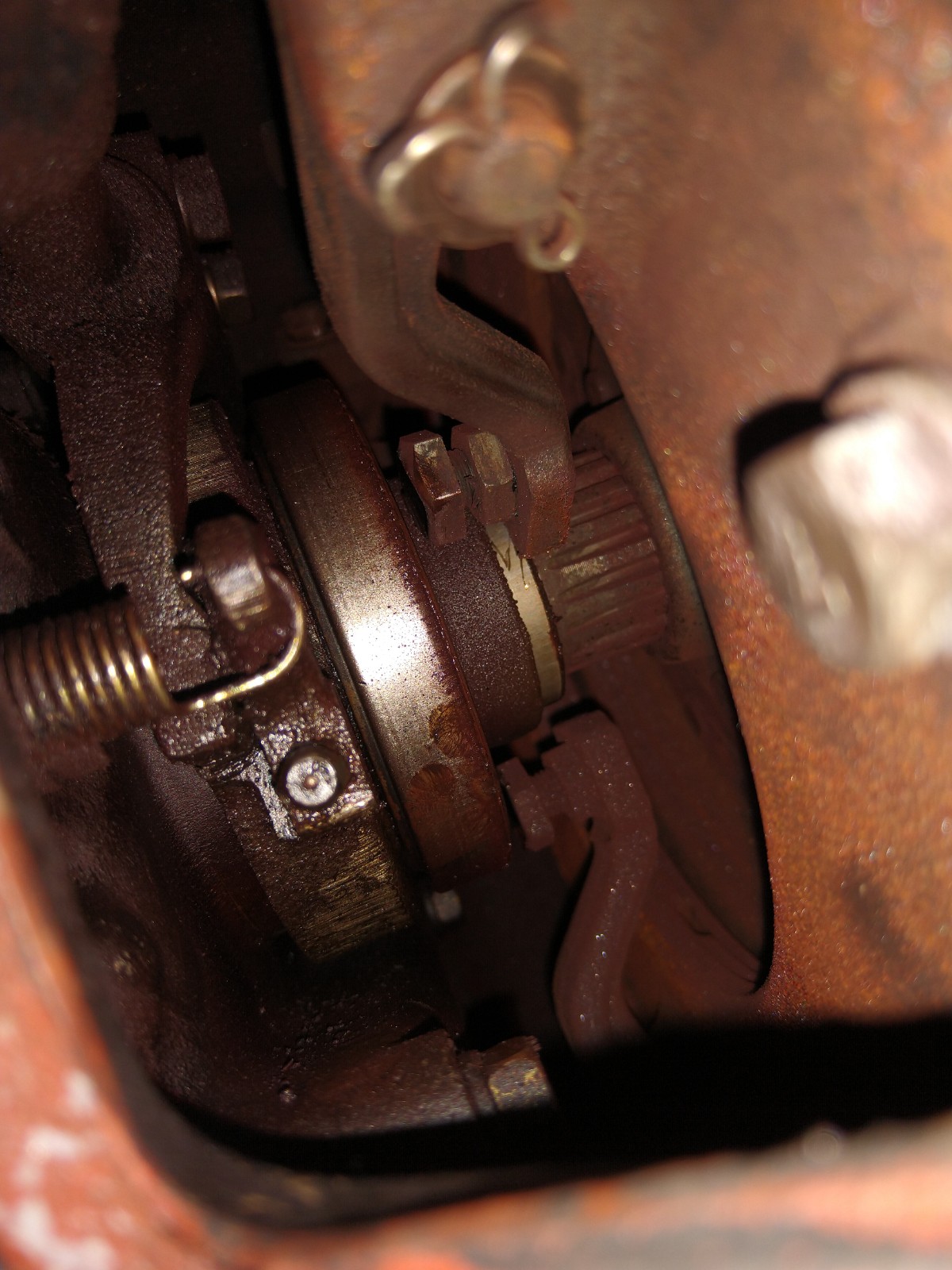

I took off the cover on the right side near the fuel filter. I assumed this was it - I didn't see anything else that looked likely.

I didn't see anything that looked like what was shown in the manual directions. I did see what looked like an adjustable bolt, but the locking nut was on the same side as the head, which doesn't look to be the case in the instructions above. Here's what I see:

Now that I post the picture, I see another similar bolt on a similar arm below it, so now I'm sure that's not what the instructions above refer to.

It looks like I'm way off base here. I hope someone can clue me in.

Thanks.

Edit: As it is now, when I start the engine with the PTO engaged and clutch all the way in, the PTO turns.

Not so. Today I had the auger hooked up and while it did engage the 1st time, the 2nd time I tried it would just grind again. So I parked it and looked to adjust the clutch. Mine has the dual disk/stage clutch, so there is the pedal free-play adjustment and then another adjustment described in the manual,

I took off the cover on the right side near the fuel filter. I assumed this was it - I didn't see anything else that looked likely.

I didn't see anything that looked like what was shown in the manual directions. I did see what looked like an adjustable bolt, but the locking nut was on the same side as the head, which doesn't look to be the case in the instructions above. Here's what I see:

Now that I post the picture, I see another similar bolt on a similar arm below it, so now I'm sure that's not what the instructions above refer to.

It looks like I'm way off base here. I hope someone can clue me in.

Thanks.

Edit: As it is now, when I start the engine with the PTO engaged and clutch all the way in, the PTO turns.

Last edited: