Hello, I'm having an issue with my L185DT. The 3PT arms won't lift. I've never had an issue with them before, and they were working just fine a two days ago. I had the tractor off and parked, with a mower lifted in the air. I lowered the mower today and now when I try to lift it nothing happens.

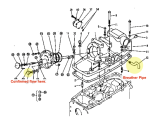

The flow control knob under the the seat, I know it only controls the lowering of the arms, has a 17mm plug/bolt right under it, and I've pulled it and confirmed the fluid is flowing.

I used the fill plug to confirm the hydraulic fluid is at the correct level. All fluids and filters were changed a couple of months ago using OEM parts.

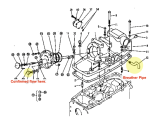

The lift arm lever feels nice and tight, no different than it always has. There is a breather pipe under the seat, if a dirt dauber got in there could that cause this issue? Does anyone know if that breather pipe just threads on and off? I don't want to try to turn it without confirming that first.

Also, my tractor has never had a front loader, so no extra hose runs to work through.

With this information, can anyone point me to some other things to look at? Maybe a process of elimination to work through? I'm fairly new to all of this, but I learn quickly...I've already rebuilt the front right axle.

Thanks!

The flow control knob under the the seat, I know it only controls the lowering of the arms, has a 17mm plug/bolt right under it, and I've pulled it and confirmed the fluid is flowing.

I used the fill plug to confirm the hydraulic fluid is at the correct level. All fluids and filters were changed a couple of months ago using OEM parts.

The lift arm lever feels nice and tight, no different than it always has. There is a breather pipe under the seat, if a dirt dauber got in there could that cause this issue? Does anyone know if that breather pipe just threads on and off? I don't want to try to turn it without confirming that first.

Also, my tractor has never had a front loader, so no extra hose runs to work through.

With this information, can anyone point me to some other things to look at? Maybe a process of elimination to work through? I'm fairly new to all of this, but I learn quickly...I've already rebuilt the front right axle.

Thanks!

Last edited: