Hey all, thanks for the kelp and info I’ve found already.

My ‘87 L2850 seems to be a “one step forward, two steps back” project. I fixed the leaky fuel filter setup, replaced the injection pump bleed cock. After that I still had engine not wanting to start warm, and varied rpm’s spraying brake cleaner around injection pump.

Ran tractor yesterday for about an hour, and parked it in shop. Later I bled it as Kubota says to (I’m used to opening up and closing while running).

I went out this morning and fired it up to check some other things (coolant bypass line I’d replaced, and reservoir), and it was dripping diesel out of injection pump lines, particularly heavy out of 1 and 2. Heavy enough that fuel was dripping below pump and onto steering shaft, nonstop quick drops to floor.

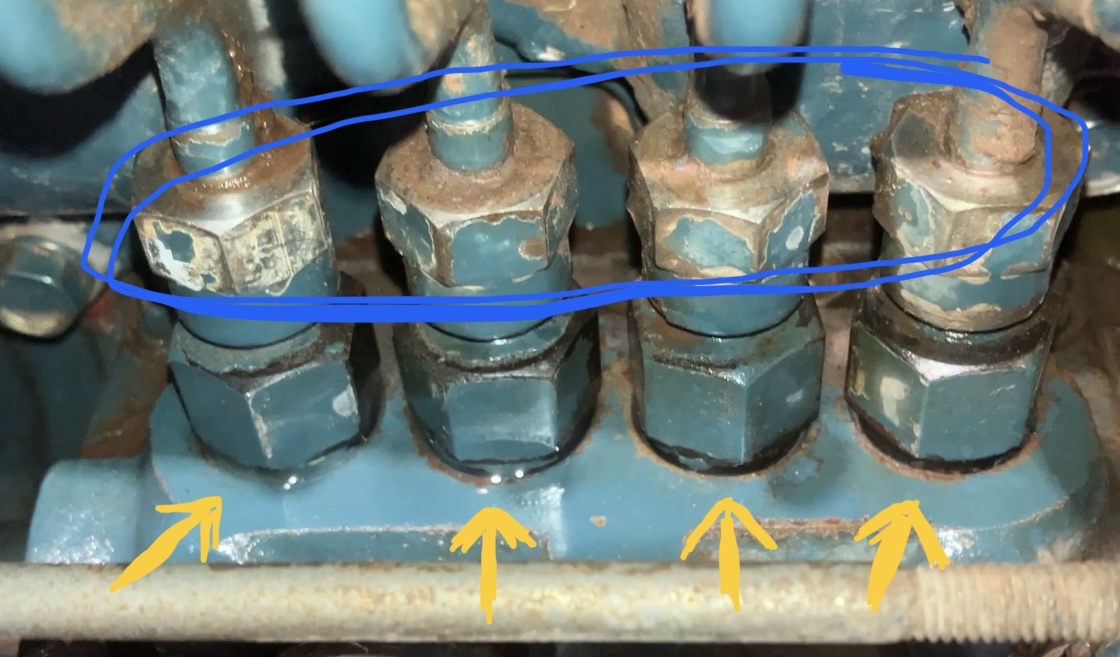

After cleaning it up, it was seeping (engine off) fuel not from the line to valve holder, but from valve holder to pump body (yellow arrows in pic). Pic is approx 15sec after shutting down and wiping clean, you can see it’s already seeping out of valve holder threads. Top of pump body was wet with fuel half a minute later.

I’m not experienced with wrenching diesels beyond 20+ yrs as an equipment operator, so I’ve got a couple questions before I go further. WSM has little info on topic and parts diagram leaves me wondering:

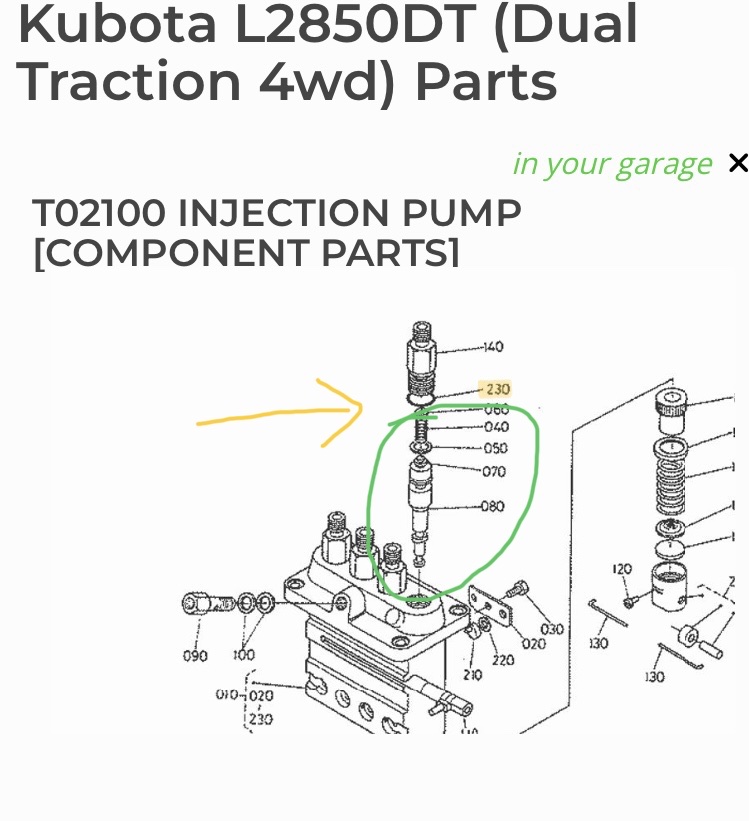

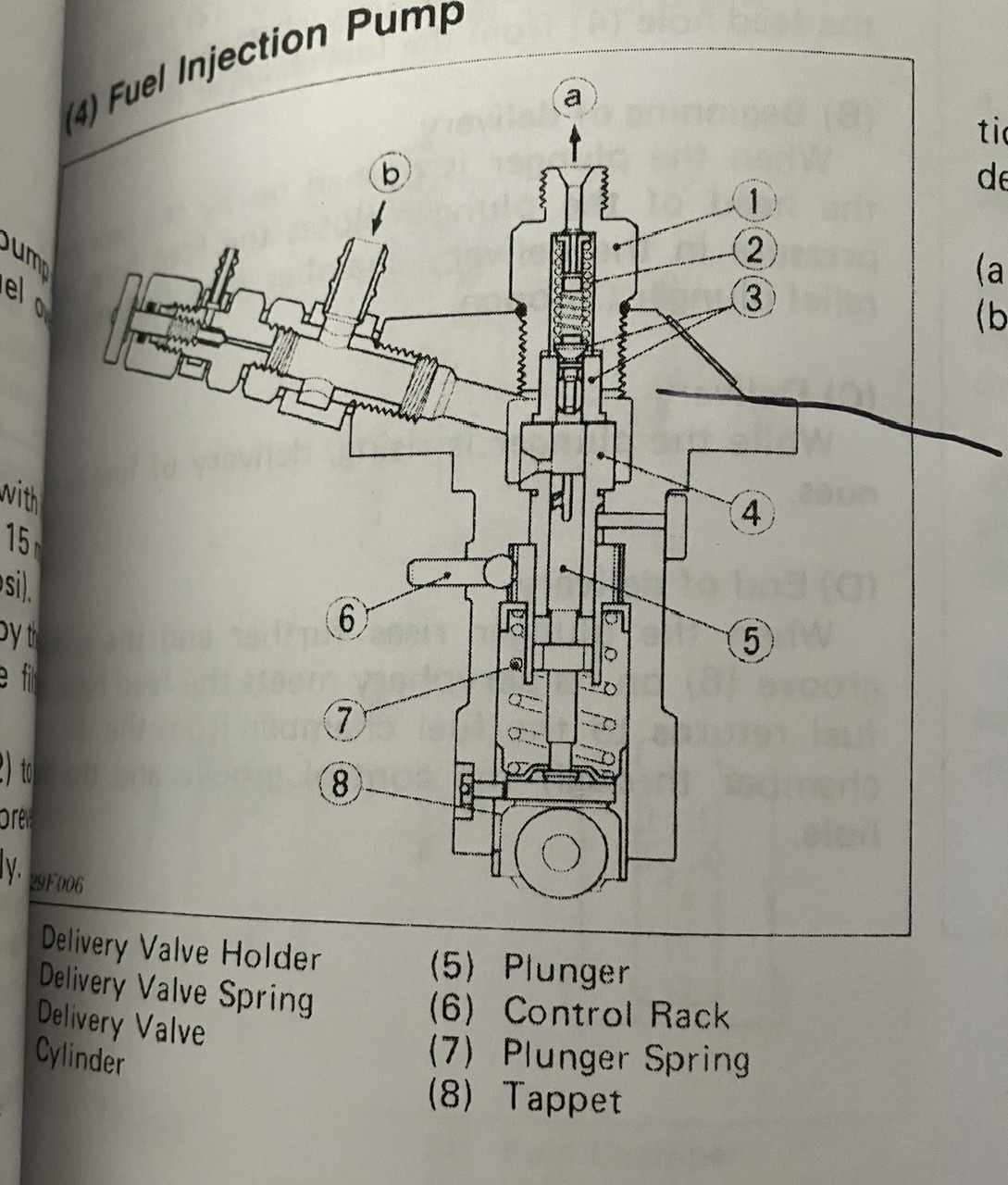

A: if I pull hard lines, can I remove the delivery valve holder from pump body and replace the o-ring shown (230 in parts diagram) without pulling valve internals (green) out that wil screw things up for me?

I’m thinking new o-rings and sealing valve holder threads with diesel rated sealant will fix my issue.

B: If I pull hard lines, are there o-rings

or seals in the compression fittings from lines to valve holders (blue in pic)? I don’t see anything in WSM or all the parts diagrams I can find.

Hopefully this is something I can do, other than puking fuel and sucking air when hot the tractor runs well, and I can move onto fixing leaky cylinders and such (the new sight glass I put in to replace the jb-weld or whatever the PO slapped on leaky sight glass at least lets me keep fluid in happy zone).

My ‘87 L2850 seems to be a “one step forward, two steps back” project. I fixed the leaky fuel filter setup, replaced the injection pump bleed cock. After that I still had engine not wanting to start warm, and varied rpm’s spraying brake cleaner around injection pump.

Ran tractor yesterday for about an hour, and parked it in shop. Later I bled it as Kubota says to (I’m used to opening up and closing while running).

I went out this morning and fired it up to check some other things (coolant bypass line I’d replaced, and reservoir), and it was dripping diesel out of injection pump lines, particularly heavy out of 1 and 2. Heavy enough that fuel was dripping below pump and onto steering shaft, nonstop quick drops to floor.

After cleaning it up, it was seeping (engine off) fuel not from the line to valve holder, but from valve holder to pump body (yellow arrows in pic). Pic is approx 15sec after shutting down and wiping clean, you can see it’s already seeping out of valve holder threads. Top of pump body was wet with fuel half a minute later.

I’m not experienced with wrenching diesels beyond 20+ yrs as an equipment operator, so I’ve got a couple questions before I go further. WSM has little info on topic and parts diagram leaves me wondering:

A: if I pull hard lines, can I remove the delivery valve holder from pump body and replace the o-ring shown (230 in parts diagram) without pulling valve internals (green) out that wil screw things up for me?

I’m thinking new o-rings and sealing valve holder threads with diesel rated sealant will fix my issue.

B: If I pull hard lines, are there o-rings

or seals in the compression fittings from lines to valve holders (blue in pic)? I don’t see anything in WSM or all the parts diagrams I can find.

Hopefully this is something I can do, other than puking fuel and sucking air when hot the tractor runs well, and I can move onto fixing leaky cylinders and such (the new sight glass I put in to replace the jb-weld or whatever the PO slapped on leaky sight glass at least lets me keep fluid in happy zone).

Last edited: