How does regeneration work?

First, there are sensors in the exhaust system that monitor EGT and exhaust pressure. The sensors tell the ECU when soot level gets excessive, and when conditions are right, the ECU will request the operator to do a regen cycle.

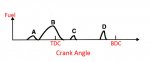

The cycle is pretty simple. While the engine is running, a tiny amount of fuel is injected at or near the the piston's bottom dead center, after the combustion cycle but near the exhaust stroke. Fuel is blown out of the engine and into the exhaust system. At the same time, the engine is also moving air. The fuel and air ignite in the DPF, which raises the temperatore of the DPF element to around 1100-1200 degrees F. At this temp, the soot is chemically changed to ash. Ash is currently considered harmless. Most of the ash is discharged out of the exhaust pipe, and no you can't see it. But you can sure feel the heat during a regen process. That is what the DPF inhibit button does. If you're in a hay barn or bush hogging in really dry grass, temporarily stopping the regen cycle isn't a bad idea to avoid fire.

How does fuel get into the crankcase? Piston engines all have some blowby. Some of the air and/or fuel will get by the rings-there is no way around it. A non DPF engine burns most of the fuel that is injected. A DPF engine, however, injects fuel that is not burned during a power stroke, so a small amount of it will get past the rings and into the oil. Especially on a cold engine. That is one reason that the L-01's will not regen if the engine temp is "cold" or "cool". It needs to be at or near operating temp, around 185-200 degrees F. At those temps, the pistons are hot, expanded as much as they are going to, and the seal is MUCH better than a cold engine. On that note, if a thermostat is stuck open, the engine won't warm up, and bad stuff happens. So the thermostat is now a big deal, where on the older stuff, they'd run fine without one or with a stuck one.

Someone mentioned the L2501. Yeah, it's a good tractor. Can it be turned up? Probably. But it's also governed to, I think 2200 RPM. So you're looking at a governor change. Because the governed RPM is low, the trans and PTO gear ratios had to be changed to compensate. So when you change the governor to allow 3000 RPM +/-, it will become extremely fast, and the PTO will over speed. Easily fixable if you know what to look for, but you'll have to split the tractor to do it.