Not sure if this should be in Implement section, but considering the valve and cylinder is involved...

I am not clear on something for the top cylinders, locking valves and float.

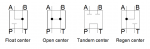

I see people installing rear remotes with floats, but then ordering the Surplus Center top links with the lock valve. To me this seems like a contradiction.

> How does a float valve work with a locking cylinder?

I also notice that Fit Right does not use a lock-valve cylinder.

Which leads to another question. I understand what the lock valve does, but if it is required,

> how come my loader cylinders carry a heavy bucket fine without a lock valve?

(For "simplicity" I went with electric valves for the rear, same setup as front joystick type. I realized I would loose float but did not realize at the time time the importance. Was figuring to use chain when required, but realize now how useful it would be. (Could still add it with another diverter... )

)

I am not clear on something for the top cylinders, locking valves and float.

I see people installing rear remotes with floats, but then ordering the Surplus Center top links with the lock valve. To me this seems like a contradiction.

> How does a float valve work with a locking cylinder?

I also notice that Fit Right does not use a lock-valve cylinder.

Which leads to another question. I understand what the lock valve does, but if it is required,

> how come my loader cylinders carry a heavy bucket fine without a lock valve?

(For "simplicity" I went with electric valves for the rear, same setup as front joystick type. I realized I would loose float but did not realize at the time time the importance. Was figuring to use chain when required, but realize now how useful it would be. (Could still add it with another diverter...