Hydraulic Thumb for the Kubota BX25-D

- Thread starter Wildfire

- Start date

Kubota_Man

Member

Equipment

BX24, Rear blade, Front blade, Snowblower, 54" MMM, Box scraper, Landscape rake

Paul I get the feeling you are holding back about what you really think about the cost of the LP 3rd function switch

I have said it before and I'm sure I'll say it again "WOW". The total package from start to finish. The cover was the icing on the cake.

Very nice Sir. You are building a BX the way I knew the BX could be.

I have said it before and I'm sure I'll say it again "WOW". The total package from start to finish. The cover was the icing on the cake.

Very nice Sir. You are building a BX the way I knew the BX could be.

Wildfire

Well-known member

Equipment

Kubota L5740 HSTC3 and a Kubota ZG222Z, 2013 BX25D,Custom Toyota fork lift.

Thank you my friend. Oh ya. It rotted my socks to know they wanted almost $500. for that switchPaul I get the feeling you are holding back about what you really think about the cost of the LP 3rd function switch

I have said it before and I'm sure I'll say it again "WOW". The total package from start to finish. The cover was the icing on the cake.

Very nice Sir. You are building a BX the way I knew the BX could be.

Until people start to complain companies will continue to act this way and it's not fair the way it is now.

I really like the BX but I need to make it my own if you know what I mean.

Yesterday I put grease fittings in the grapple. Yup. It came with none

Video: http://www.youtube.com/watch?v=VyLtnt8Eqi4

Kubota_Man

Member

Equipment

BX24, Rear blade, Front blade, Snowblower, 54" MMM, Box scraper, Landscape rake

After watching the video Paul and your portion about the milling machine.......I think your Wifey would like you get this milling machine so she doesn't have that much to clean up

Attachments

-

41.6 KB Views: 855

Gotta say.........AWESOME work, great ideas, your workshop is also to die for.

Great videos and thanks so much for going to so much trouble to make it for us

But...your weather Im not so keen on

Great videos and thanks so much for going to so much trouble to make it for us

But...your weather Im not so keen on

Dan_R_42

Member

Equipment

B7100-D, w/ Sims Cab, B219 FEL, ARPS 70 Backhoe, Oversized R4 Tires, LX2610 Cab

Once again Paul - AWESOME...

One question about the switch box mount. You mentioned you were going to use 3 set screws. The finished product appears to have 2 screws. Did you find that it was very secure with 2 screws and eliminated the 3rd ?

Your work is so awesome I always try to pay attention to all your details...

One question about the switch box mount. You mentioned you were going to use 3 set screws. The finished product appears to have 2 screws. Did you find that it was very secure with 2 screws and eliminated the 3rd ?

Your work is so awesome I always try to pay attention to all your details...

Lil Foot

Well-known member

Lifetime Member

Equipment

1979 B7100DT Gear, Nissan Hanix N150-2 Excavator

Man, I thought my Servo Micromill was small!After watching the video Paul and your portion about the milling machine.......I think your Wifey would like you get this milling machine so she doesn't have that much to clean up

Attachments

-

54.3 KB Views: 532

-

35.2 KB Views: 589

-

7 KB Views: 494

Wildfire

Well-known member

Equipment

Kubota L5740 HSTC3 and a Kubota ZG222Z, 2013 BX25D,Custom Toyota fork lift.

Oh ya. Wifey wouldn't mind cleaning that one for sureAfter watching the video Paul and your portion about the milling machine.......I think your Wifey would like you get this milling machine so she doesn't have that much to clean up

Hey your welcome and thank YOU for watching them. I'm uploading a new video tonight. It's about adding a fuel filter assembly from a Grand L to a BX25-D. It's 65 minutes longGotta say.........AWESOME work, great ideas, your workshop is also to die for.

Great videos and thanks so much for going to so much trouble to make it for us

But...your weather Im not so keen on

We got four loads of snow on the way for the next six days.

Thanks Dan. Man you got a good eye. Yes my intentions was to put three set screws in the switch box but after putting in two of the I new it was enough and the third wasn't needed.Once again Paul - AWESOME...

One question about the switch box mount. You mentioned you were going to use 3 set screws. The finished product appears to have 2 screws. Did you find that it was very secure with 2 screws and eliminated the 3rd ?

Your work is so awesome I always try to pay attention to all your details...

I appreciate your kind words. Thank you very much.

It is smallMan, I thought my Servo Micromill was small!

Lil Foot

Well-known member

Lifetime Member

Equipment

1979 B7100DT Gear, Nissan Hanix N150-2 Excavator

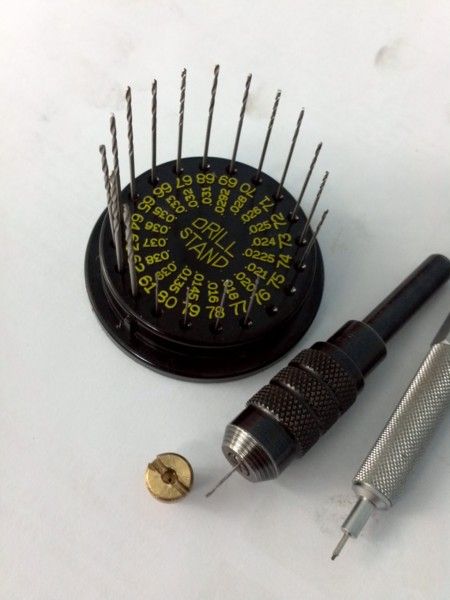

Yeah, not much good for hoggin', but that's what the V-mill is for. Did a lot of tiny, fine stuff with an identical one when I was in research; vacuum metal deposition masks in SS & Berylium Copper, (before photolith was around) wee little stainless u-joints, (for .020 shafting) & gas orifices…… drilled some 17-4PH stainless gas restricter orifices .013 diameter .400 deep, and some more .006 diameter .125 deep.It is small

Think I've still got some of those drills bits in one of my tool boxes….

Kubota_Man

Member

Equipment

BX24, Rear blade, Front blade, Snowblower, 54" MMM, Box scraper, Landscape rake

Me neitherFoot I aint got a clue what you just said but Im impressed, I think

Lil Foot

Well-known member

Lifetime Member

Equipment

1979 B7100DT Gear, Nissan Hanix N150-2 Excavator

Foot I aint got a clue what you just said but Im impressed, I think

LMAO….. Thanks guys, probably sounds more impressive than it is, but I will admit that drilling holes that small, that deep in 17-4PH Stainless was a cast iron bitch….. the average human hair usually runs .003 to .008 in diameter.Me neither

I know what you mean Lil Foot, I use these drills for jetsLMAO….. Thanks guys, probably sounds more impressive than it is, but I will admit that drilling holes that small, that deep in 17-4PH Stainless was a cast iron bitch….. the average human hair usually runs .003 to .008 in diameter.

Hair from certain parts of the anatomy of certain ethnicities can even get up to 0.012"

Last edited:

Lil Foot

Well-known member

Lifetime Member

Equipment

1979 B7100DT Gear, Nissan Hanix N150-2 Excavator

Brings to mind that old standard machining unit of measurement, the RCH.Hair from certain parts of the anatomy of certain ethnicities can even get up to 0.012"

We use different standards here in OZ for small units, like the poofteenth, beezdick and the FHBrings to mind that old standard machining unit of measurement, the RCH.

So does anyone have the specs of Red vs Blonde vs Brunette?Brings to mind that old standard machining unit of measurement, the RCH.

Hey paul 2 more storm fronts coming thru this week headed up the coast to you.Thank you my friend. Oh ya. It rotted my socks to know they wanted almost $500. for that switch

Until people start to complain companies will continue to act this way and it's not fair the way it is now.

I really like the BX but I need to make it my own if you know what I mean.

Yesterday I put grease fittings in the grapple. Yup. It came with none

Video: http://www.youtube.com/watch?v=VyLtnt8Eqi4

I have a question on threading , it would be really nice to have a lathe to hold my tap straight.lol

The question is how far do you go before backing up (chip busting?) is it different for different size threads. Threading with a die is where i usually end up with a mishapen or broken thread somewhere along the thread run.

Wildfire

Well-known member

Equipment

Kubota L5740 HSTC3 and a Kubota ZG222Z, 2013 BX25D,Custom Toyota fork lift.

I think winter is here to stayHey paul 2 more storm fronts coming thru this week headed up the coast to you.

I have a question on threading , it would be really nice to have a lathe to hold my tap straight.lol

The question is how far do you go before backing up (chip busting?) is it different for different size threads. Threading with a die is where i usually end up with a mishapen or broken thread somewhere along the thread run.

I usually go 2-3 revolutions before I back out again. Some people go less than that but I'm a little impatient lol. I like to keep the cutting fluid on the thread as well. That's the real trick to a good thread in my opinion.

Wildfire

Well-known member

Equipment

Kubota L5740 HSTC3 and a Kubota ZG222Z, 2013 BX25D,Custom Toyota fork lift.

I use that as her video name. Most of the time I call her "Mudder"Paul, my Dad is the only person I have ever heard called there wife, "wifey".