I was having the tractor picked up this evening for repair, and hastily went to adjust the directional valve (having never done so before) since I have the loader removed.

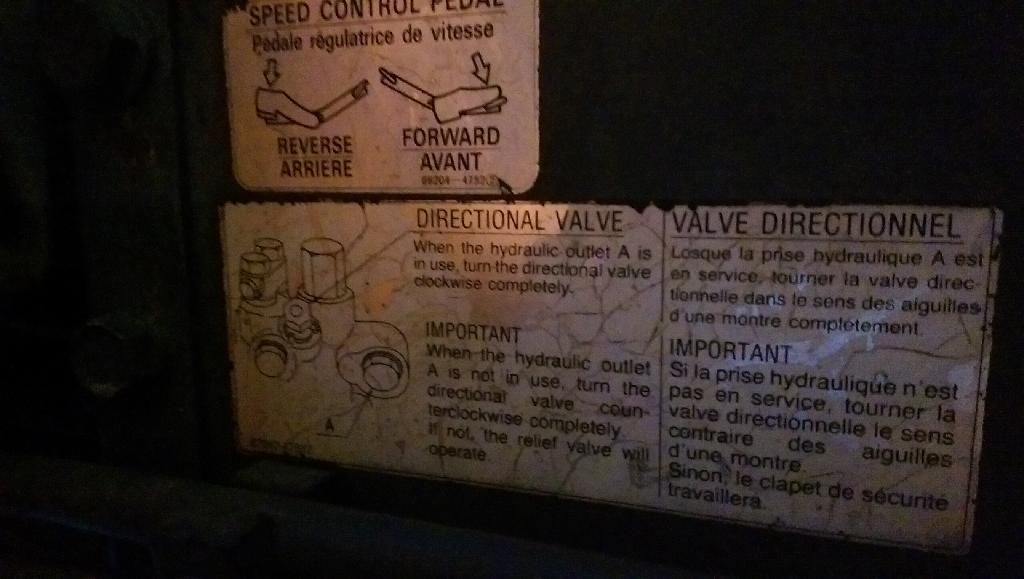

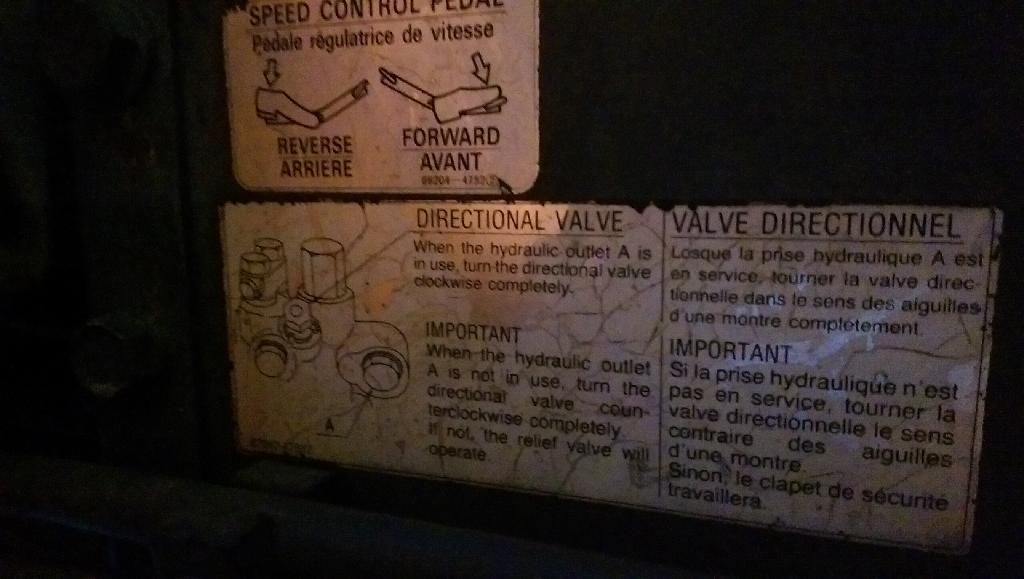

The label on the tractor (pictured below) says "When the hydraulic outlet A is not in use, turn the directional valve counterclockwise completely. If not the relief valve will operate" (presumably what I should do when the loader is disconnected).

In poor light I thought the pin sticking out of it was a cotter pin preventing it from rotating. So I bent one out of the way thinking this was a screw/bolt that I wanted to turn until it stopped, and found that the valve can turn many revolutions (perhaps indefinitely) in either direction.

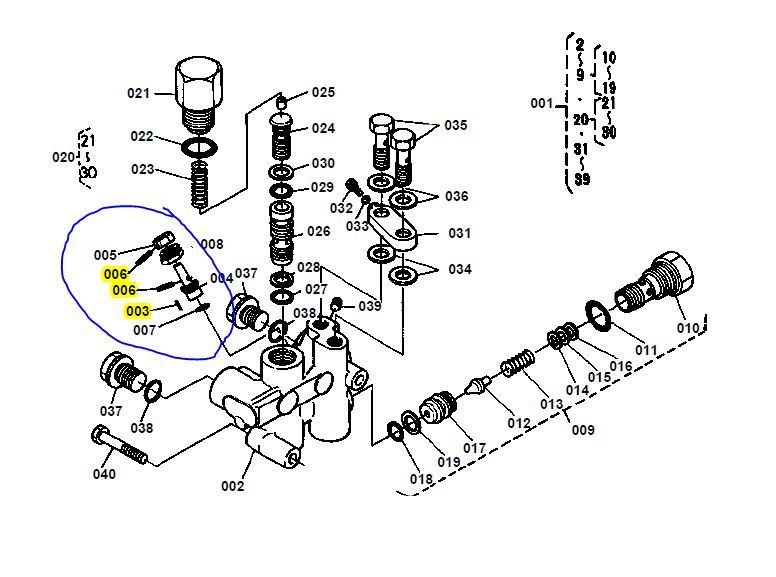

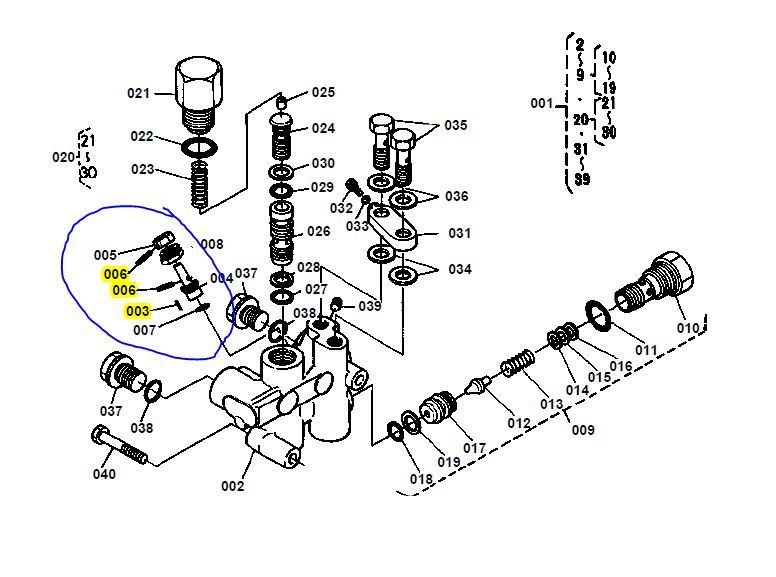

Now I see that what I bent out of the way was supposed to be a rotation stop but I still don't understand how it works. In use is is only supposed to be able to turn less than 360 degrees? Are there supposed to be two stops so it can just travel in an arc?

It had been wired in place so it could barely turn at all. I removed the wire.

I need to know what to do with this before I put the loader back on. And will it hurt the tractor to run it how it is now without the loader connected?

In the third image of the parts diagram 003 and 006 are "SPRING,PIN". And the loader worked great before I messed with anything.

The label on the tractor (pictured below) says "When the hydraulic outlet A is not in use, turn the directional valve counterclockwise completely. If not the relief valve will operate" (presumably what I should do when the loader is disconnected).

In poor light I thought the pin sticking out of it was a cotter pin preventing it from rotating. So I bent one out of the way thinking this was a screw/bolt that I wanted to turn until it stopped, and found that the valve can turn many revolutions (perhaps indefinitely) in either direction.

Now I see that what I bent out of the way was supposed to be a rotation stop but I still don't understand how it works. In use is is only supposed to be able to turn less than 360 degrees? Are there supposed to be two stops so it can just travel in an arc?

It had been wired in place so it could barely turn at all. I removed the wire.

I need to know what to do with this before I put the loader back on. And will it hurt the tractor to run it how it is now without the loader connected?

In the third image of the parts diagram 003 and 006 are "SPRING,PIN". And the loader worked great before I messed with anything.

Last edited: