I need some insight from the collective brain trust of the forum members.

Recently purchased a L4740-3 Cab tractor that came with a Woods 3-pt Quick Hitch. The QH seems like a great time saver when swapping implements, but ran into a number of issues when testing on current inventory of older implements.

Hooking up to the ballast box is simple enough as it is QH compatible (according to I-match sticker on it). Back blade and wood chipper need the upper link modified to accept the hook as they were built prior to QH compatibility.

Where I'm a bit stumped is with the finish mower and brush hog. Both are older Land Pride models using the swinging upper link. My question is how are these suppose to work or what am I missing? The photos below should help clarify the issues. I'm under the impression the upper link must move to accommodate uneven surfaces, which is mandatory in my situation. Keep in mind the QH has some type of additional linkage that I'm not certain what its function is or when to use it.

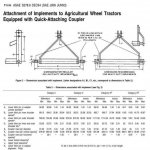

The upper link position varies between implements necessitating a height change to the upper link hook. This seems to defeat some advantage of the QH. Can someone point me to the QH compatibility standards, so I can modify the implement upper linkage to be dimensionally correct?

Considering the tractor has the deluxe telescoping 3-pt hitch linkages is the QH a waste of time?

Thanks in advance for your input.

Recently purchased a L4740-3 Cab tractor that came with a Woods 3-pt Quick Hitch. The QH seems like a great time saver when swapping implements, but ran into a number of issues when testing on current inventory of older implements.

Hooking up to the ballast box is simple enough as it is QH compatible (according to I-match sticker on it). Back blade and wood chipper need the upper link modified to accept the hook as they were built prior to QH compatibility.

Where I'm a bit stumped is with the finish mower and brush hog. Both are older Land Pride models using the swinging upper link. My question is how are these suppose to work or what am I missing? The photos below should help clarify the issues. I'm under the impression the upper link must move to accommodate uneven surfaces, which is mandatory in my situation. Keep in mind the QH has some type of additional linkage that I'm not certain what its function is or when to use it.

The upper link position varies between implements necessitating a height change to the upper link hook. This seems to defeat some advantage of the QH. Can someone point me to the QH compatibility standards, so I can modify the implement upper linkage to be dimensionally correct?

Considering the tractor has the deluxe telescoping 3-pt hitch linkages is the QH a waste of time?

Thanks in advance for your input.

Attachments

-

95.7 KB Views: 377

-

92.9 KB Views: 371