I had recently bought a Lock and Load grease gun fitting which is a fantastic item. A friend of mine mentioned that there is a needle fitting that attaches to the lock and load fitting. So, went to Napa and they have their own brand which is pretty good so I picked up a kit. Their part number is 700-1193. For those who never used this it is a great addition to your maintenance. I use it for the ball joints that no longer have grease fittings. Just insert into the rubber cup and squeeze the gun. I also use it on my lawn mower and auto. It is pretty handy. The needle is about the size of a doctors needle so the hole is extremely small. Just thought I pass this along.

Grease gun needle fitting

- Thread starter Mondo

- Start date

Rock Auto $1.22...

Watch the shipping costs, however...

https://www.rockauto.com/en/tools/garage+equipment,grease+gun,grease+gun+needle,407

Also my go to place for Wix filters, both the plain and XP versions.....

Watch the shipping costs, however...

https://www.rockauto.com/en/tools/garage+equipment,grease+gun,grease+gun+needle,407

Also my go to place for Wix filters, both the plain and XP versions.....

Problem with any grease needle is, once you perforate the boot, you are allowing water to get into the joint. Probably ok on a tractor but not so good on a vehicle where there is water pressure on the suspension parts as you drive on wet, rainy roads.

I have one. rarely use it for anything except getting grease in sealed bearings.

I have one. rarely use it for anything except getting grease in sealed bearings.

Chilliwack Murray

Member

Equipment

B7510 with loader and BH4672 backhoe, JD400 industrial Backhoe, B6100.

A grease needle is a great tool can make a lot of disposable bearings and ball joints last almost forever but you should never create a new hole when using it. Gently work it through the existing opening of the ball joint and fill it with new grease.

For bearings, if at all possible, pry out the grease seal from the stationary edge and put grease in that way. You can use the needle to get into the cage. If you can’t remove the grease seal a needle may get past the seal lip but you’d have to be very careful not to damage it.

For bearings, if at all possible, pry out the grease seal from the stationary edge and put grease in that way. You can use the needle to get into the cage. If you can’t remove the grease seal a needle may get past the seal lip but you’d have to be very careful not to damage it.

I only paid $6.00 at Napa for 2 of them in the package.

Also I agree on the auto issue, Its not like I grease after every oil change, its an occasional thing. great for items like tractors that you mentioned and places where you would usually spray graphite, lube, etc. It is a lot cleaner. It has its purpose.

Also I agree on the auto issue, Its not like I grease after every oil change, its an occasional thing. great for items like tractors that you mentioned and places where you would usually spray graphite, lube, etc. It is a lot cleaner. It has its purpose.

I'd sure like to know where the 'existing hole' is in a sealed ball joint or tie rod end, I've never seen one, could you elaborate on that??A grease needle is a great tool can make a lot of disposable bearings and ball joints last almost forever but you should never create a new hole when using it. Gently work it through the existing opening of the ball joint and fill it with new grease.

For bearings, if at all possible, pry out the grease seal from the stationary edge and put grease in that way. You can use the needle to get into the cage. If you can’t remove the grease seal a needle may get past the seal lip but you’d have to be very careful not to damage it.

Lil Foot

Well-known member

Lifetime Member

Equipment

1979 B7100DT Gear, Nissan Hanix N150-2 Excavator

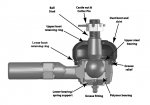

Like these:I'd sure like to know where the 'existing hole' is in a sealed ball joint or tie rod end, I've never seen one, could you elaborate on that??

Attachments

-

77.8 KB Views: 276

-

11.6 KB Views: 238

-

81.9 KB Views: 229

Chilliwack Murray

Member

Equipment

B7510 with loader and BH4672 backhoe, JD400 industrial Backhoe, B6100.

Between the boot and the stud would be the obvious choice. On some you can get between the boot and socket body but not if they have a wire retaining clip that sits in a groove.

If you have to put a hole in the boot at least plug it up with RTV. I don’t think I’ve ever had to punch a hole in anything to get grease in with a grease needle in almost 30 years as a mechanic.

Belt tensioners and idlers will often last the life of the vehicle when they get greased whenever a belt is removed or replaced. Most of our vehicles were still running well and had the original idlers when we passed them on with over 400k km on them. So a grease needle is a useful tool if you use it correctly.

If you have to put a hole in the boot at least plug it up with RTV. I don’t think I’ve ever had to punch a hole in anything to get grease in with a grease needle in almost 30 years as a mechanic.

Belt tensioners and idlers will often last the life of the vehicle when they get greased whenever a belt is removed or replaced. Most of our vehicles were still running well and had the original idlers when we passed them on with over 400k km on them. So a grease needle is a useful tool if you use it correctly.

Lil Foot

Well-known member

Lifetime Member

Equipment

1979 B7100DT Gear, Nissan Hanix N150-2 Excavator

"non greasable" ball joints and tie rod ends are non greasable because they are lubricated with the PROPER lubricant at their factory, then sealed up. A lot of them have a nylon seat to which the ball rides against, which never needs lubrication. Once they wear out (or IF they wear out....), they are to be replaced.

Most people over-grease them or use the wrong type grease if they grease them at all-which is exactly why many manufacturers are slowly getting away from greasable joints. Look at deck spindles....great example.

Most people over-grease them or use the wrong type grease if they grease them at all-which is exactly why many manufacturers are slowly getting away from greasable joints. Look at deck spindles....great example.

For kicks and grins, I was out and about yesterday and crawled under my pickup truck and the wide's Suburban and took a hard look at ll the various joints and none of them have any access on any of the rubber boots to add grease and on all of them, the bottom of the boot is securely fastened to joint with a metal ring so no way you could get under it.

While there may be boots that you can put grease in, none of mine are like that. Not on the Kubota tie rod ends either, Same metal ring arrangement.

While there may be boots that you can put grease in, none of mine are like that. Not on the Kubota tie rod ends either, Same metal ring arrangement.

Chilliwack Murray

Member

Equipment

B7510 with loader and BH4672 backhoe, JD400 industrial Backhoe, B6100.

Like I said, on most you would have to put the needle between the boot and the stud meaning you would only be able to grease it when it was apart. The only ones that are usually taken apart without being destroyed are tie rod ends.

The whole point I was trying to make was don’t make and leave a hole in the boot with a grease needle or you are defeating the purpose of adding grease.

The whole point I was trying to make was don’t make and leave a hole in the boot with a grease needle or you are defeating the purpose of adding grease.

Modern RAM Heavy Duty pickups use a double cardan joint on the front 4x4 driveshaft. There is a sticker under the hood specifically stating to use a needle to grease a specific point on the double u-joint, every oil change. Awkward as heck to get at, but that is another use for the needle greaser...