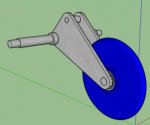

I designed (3d CAD) , machined and built this pretty cool attachment for installing electronic dog fencing wire.

I can cut up to about 4" deep although the wire only needs to be about 1-2" into the ground. This cutting wheel is 1" thick with a very sharp 120 degree cutting edge. All the arms and hardware are 304 stainless.

It works VERY well when the ground is damp. It has easily enough power to lift the whole rear end off the ground if the ground is to hard.

I have a long set of hoses that have quick connects from the cylinder to the FEL ports for now. May eventually install the BX7326 Rear AUX kit for this and a log splitter that I want to make.

I can cut up to about 4" deep although the wire only needs to be about 1-2" into the ground. This cutting wheel is 1" thick with a very sharp 120 degree cutting edge. All the arms and hardware are 304 stainless.

It works VERY well when the ground is damp. It has easily enough power to lift the whole rear end off the ground if the ground is to hard.

I have a long set of hoses that have quick connects from the cylinder to the FEL ports for now. May eventually install the BX7326 Rear AUX kit for this and a log splitter that I want to make.

Attachments

-

96.8 KB Views: 659

-

96.3 KB Views: 611

-

88.7 KB Views: 703

-

9.2 KB Views: 573

-

89.2 KB Views: 589

Last edited: