I wanted to add some 'recovery points' to the front of my tractor since Kubota offered nothing (front or rear).

In the rear....its a simple matter of rigging something on a tow bar or just adding a shackle/other to the that spot. I already have a twisted shackle in the rear, so nothing more needed there.

In the front however, I wanted two things:

1. A 'D' Ring to pull 'light' loads with in reverse. (It's a patently bad idea to pull heavy loads in reverse, if you want your ring gear(s) to survive.

2. Some strong 'recovery' points to use in the event I am stuck (again) and need to pull myself out forward.

You don't want to apply heavy loads to either your FEL (if equipped) or your front axle (that's not what its there for).

Pulling from one or more points on the 'frame' is what 'should' be done.

There are any number of ways to achieve this. Some as simple as bolting on common recovery 'hooks' or more elaborate means requiring bolting/welding on various plates, hooks, clevis' or loops. Whatever you feel is best or what the construction of your tractor frame dictates.

In my case, I will never have the front loader off the tractor and where it bolts to the tractor frame is a very strong point. A good place to attach recovery 'points' since the metal is double thick there.

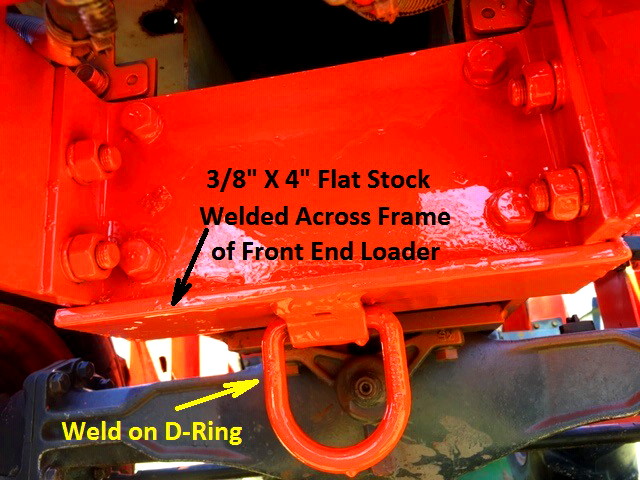

So the first thing I did was was weld a 3/8" X 4" wide piece of Flat Stock across the frame of the FEL and welded a 'D' ring in the center of that (for very LIGHT duty pulling).

Without first removing the FEL and some of the of the front panels.....I would not be able to get my Wire Welder inside the framework to make the Flat Stock 'flush' with the outside of the frame.

So instead, I cut it a bit longer than the width of the frame and was able to reach that with 7018 electrodes....using my stick welder.

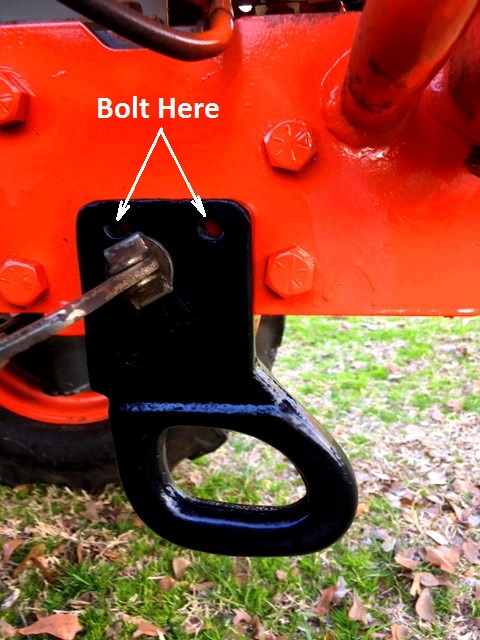

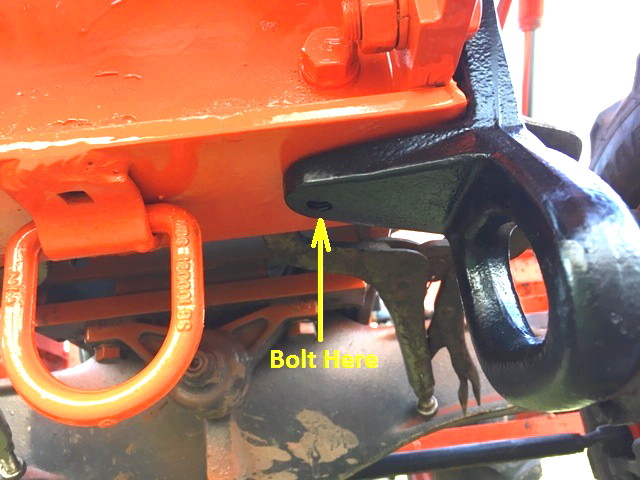

There is an offset at the top of the recovery loops I have....so this worked out well anyway. The protrusion at the bottom matched the offset at top and provides 3 points of contact that way.

I already had some heavy duty loops to use.

Flat stock and 'D' Ring welded to frame:

Recovery Loops in place....to mark holes for bolts (some are through bolts, some threaded) will install bolts tomorrow.

In the rear....its a simple matter of rigging something on a tow bar or just adding a shackle/other to the that spot. I already have a twisted shackle in the rear, so nothing more needed there.

In the front however, I wanted two things:

1. A 'D' Ring to pull 'light' loads with in reverse. (It's a patently bad idea to pull heavy loads in reverse, if you want your ring gear(s) to survive.

2. Some strong 'recovery' points to use in the event I am stuck (again) and need to pull myself out forward.

You don't want to apply heavy loads to either your FEL (if equipped) or your front axle (that's not what its there for).

Pulling from one or more points on the 'frame' is what 'should' be done.

There are any number of ways to achieve this. Some as simple as bolting on common recovery 'hooks' or more elaborate means requiring bolting/welding on various plates, hooks, clevis' or loops. Whatever you feel is best or what the construction of your tractor frame dictates.

In my case, I will never have the front loader off the tractor and where it bolts to the tractor frame is a very strong point. A good place to attach recovery 'points' since the metal is double thick there.

So the first thing I did was was weld a 3/8" X 4" wide piece of Flat Stock across the frame of the FEL and welded a 'D' ring in the center of that (for very LIGHT duty pulling).

Without first removing the FEL and some of the of the front panels.....I would not be able to get my Wire Welder inside the framework to make the Flat Stock 'flush' with the outside of the frame.

So instead, I cut it a bit longer than the width of the frame and was able to reach that with 7018 electrodes....using my stick welder.

There is an offset at the top of the recovery loops I have....so this worked out well anyway. The protrusion at the bottom matched the offset at top and provides 3 points of contact that way.

I already had some heavy duty loops to use.

Flat stock and 'D' Ring welded to frame:

Recovery Loops in place....to mark holes for bolts (some are through bolts, some threaded) will install bolts tomorrow.

Last edited: