I assume it bogs down even when running at high throttle settings? These engines are designed to make best power and torque up near full throttle. If it doesn't bog down at full throttle, then that's probably the way it was intended.

It will take the same amount of power from the engine to lift the bucket no matter how you drive the pump. Power = torque x speed. If your engine has lots of torque, you can generate the required power at lower speed than if the engine has less torque.

Since you can't change the engine's torque (well, not without adding a turbo or something), then you can reduce the speed at which you are lifting the load. Three ways to do that: gear down by using the PTO to drive the pump, replace the pump with a smaller one, or increase the diameter of the lift cylinders.

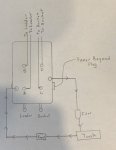

The first assumes the existing pump is not already geared down as much as the PTO by chain and sprockets between the crankshaft and the pump. If there are a chain and sprockets, that opens up a third possibility: changing the sprockets to provide a lower pump speed.

In all cases, you will have to run the engine at a high RPM to make the power. "So why bother, I'm already running it at high RPM because it is bogging down?" you might well ask. My response would be that it is easier on the engine to run it at a constant high rpm and demand within it's torque curve than it is to have the engine bog down because it doesn't have enough torque to meet the demand.