Hello,

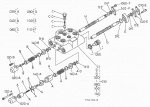

I have a FEL that won't hold it's tilt. When I fully curl the bucket back, it will slowly start to dump. Once it gets past a certain point it will dump rapidly. I think I have narrowed it down to a control valve(B00101) and not a cylinder issue. After swapping the hoses around on the control valve, I was no longer able to curl the bucket. The boom raise and lowering seem to be working fine. After looking at the parts diagram on Messicks, it looks like I might be able to rebuild or replace the seals on the valve rather than replacing the whole unit. Looking for some guidance on multiple fronts here guys, and eager to learn.

Will it fix my issue? Is this the issue?

How hard would the job be?

How do I know what seals or parts to replace for just the one malfunctioning

valve? Or Should I replace everything?

Pics

https://imgur.com/a/G39eibD

Parts diag- I think.

https://www.messicks.com/ku/85591?sectionId=221297&diagramId=379157

Any help would be great.

Thanks guys!

I have a FEL that won't hold it's tilt. When I fully curl the bucket back, it will slowly start to dump. Once it gets past a certain point it will dump rapidly. I think I have narrowed it down to a control valve(B00101) and not a cylinder issue. After swapping the hoses around on the control valve, I was no longer able to curl the bucket. The boom raise and lowering seem to be working fine. After looking at the parts diagram on Messicks, it looks like I might be able to rebuild or replace the seals on the valve rather than replacing the whole unit. Looking for some guidance on multiple fronts here guys, and eager to learn.

Will it fix my issue? Is this the issue?

How hard would the job be?

How do I know what seals or parts to replace for just the one malfunctioning

valve? Or Should I replace everything?

Pics

https://imgur.com/a/G39eibD

Parts diag- I think.

https://www.messicks.com/ku/85591?sectionId=221297&diagramId=379157

Any help would be great.

Thanks guys!

Last edited: