Man, fancy pilot shaft! I remember using a wooden dowel and wrap black tape around it until I got close, and it worked pretty good.

Farmall H restoration

- Thread starter Yooper

- Start date

RCW

Well-known member

Lifetime Member

Equipment

BX2360, FEL, MMM, BX2750D snowblower. 1953 Minneapolis Moline ZAU

Blew the clutch on my ‘71 Javelin back in high school. Put it on the hoist at my dad’s gas station to replace it. Thought I could eyeball the new clutch disc for reassembly. Me and my buddy struggled for about an hour trying to get the transmission back in. When my dad asked how I aligned the disc and I told him, he had all he could do to bust out laughing. We took it apart and used the transmission input shaft to align it and then it assembled just fine. One of those things you learn the hard way and you never forget!Man, fancy pilot shaft! I remember using a wooden dowel and wrap black tape around it until I got close, and it worked pretty good.

Thanks buddy! Appreciate the feedback!@Yooper - as I’ve said several times before, I’m so entertained by your work and envious of your skills.

Very much enjoy following your projects.

Thanks for documenting them so well.

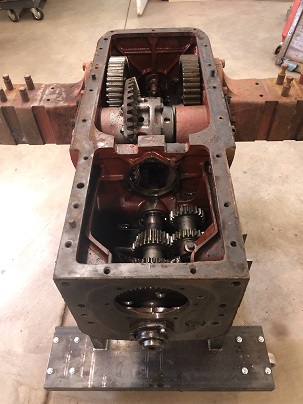

Built a stand with caster wheels for the final disassembly. It will allow me to work on the transmission and axles and when the time comes, to blast and paint.

fried1765

Well-known member

Equipment

Kubota L48 TLB, Ford 1920 FEL, Ford 8N, SCAG Liberty Z, Gravely Pro.

Yup......only wood dowel (Ford 1920) here too.Man, fancy pilot shaft! I remember using a wooden dowel and wrap black tape around it until I got close, and it worked pretty good.

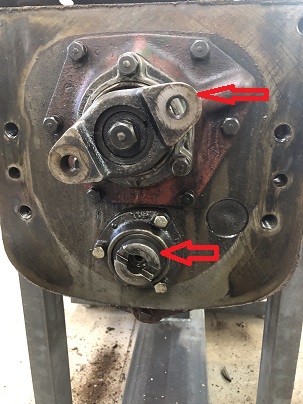

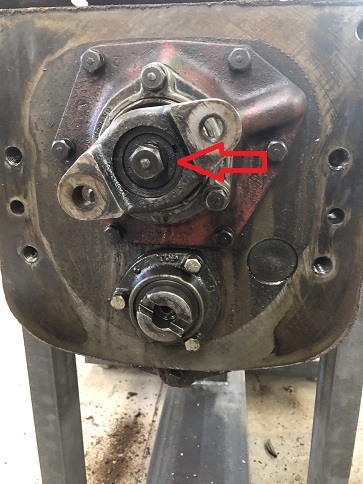

One of the questions I had on this tractor just got answered. A couple of years after I bought it I remember helping my dad remove the hydraulic pump from the clutch housing. I was in school at the time and could only help him a few hours a day and I wasn't around when he made this repair on the throw out bearing support. To get at this you have to remove the pump. I'll be making my own part out of steel. Should be a fun challenge. Tractor is looking pretty small right now.

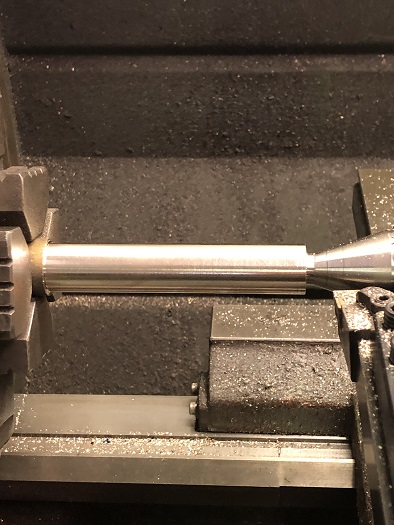

Had a piece of steel laser cut to my specs to make a new throw out bearing support. Welded a piece of two inch round stock to it and spent the day machining it to spec. Happy with the results!

Nothing too heavy this week. Just built up the ends of the clutch shaft and turned them to size on the lathe. Also built up the throw out bearing fork and milled that back to spec. Also replaced the pins in the throw out bearing along with the bearing itself. Then started taking apart the transmission.

fried1765

Well-known member

Equipment

Kubota L48 TLB, Ford 1920 FEL, Ford 8N, SCAG Liberty Z, Gravely Pro.

Excellent job!Nothing too heavy this week. Just built up the ends of the clutch shaft and turned them to size on the lathe. Also built up the throw out bearing fork and milled that back to spec. Also replaced the pins in the throw out bearing along with the bearing itself. Then started taking apart the transmission.

View attachment 123020 View attachment 123021

View attachment 123022 View attachment 123024

View attachment 123023

Wish I had the talent, and the equipment for that type work!

Pretty much disassembled down to as far as I'm going to go. Got a nice day coming up early next week to power wash parts so in the mean time I'll rebuild some parts. Starting with the reverse gear shaft and bushings.

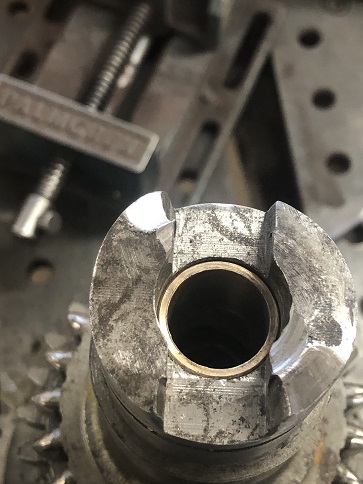

Pressed the bushings out of the gears and made some new ones out of Ampco bronze that I had on hand. Pressed them in and reamed to size. I also added a hole in the gear casting for oiling the bushings. Carbide drill got that done.

Working on the two input shafts couplers on the transmission. Both have seal surfaces that are worn. I made a whole new pto coupling nut out of 4140.

On the main transmission coupler, somehow the surfaces of the seal and the coupler got damaged. Scratching my head here as it looks like something got jammed in between the coupler and the seal housing. But what happened is anyone's guess.

I machined the coupler surface down and made a sleeve out of 4140. Pressed it on with some red Loctite and machined it down to size and polished the surface.

Tomorrow is going to be a good day to power wash the housings and then reassembly will follow.

I machined the coupler surface down and made a sleeve out of 4140. Pressed it on with some red Loctite and machined it down to size and polished the surface.

Tomorrow is going to be a good day to power wash the housings and then reassembly will follow.

Rebuilding the pto driveshaft. I started by turning down the forward end that rides in the countershaft bushing. This end was worn over .015" but it really didn't have to be a certain size. So I turned it down to where it just cleaned up and then machined an undersize bushing and brought that into size on the lathe with the help of the steady rest.

Starting to reassemble the transmission. The woodruff key on the drive coupler was pretty beat up so I decided to make one due to the fact this key is kind of an oddball size. (Woodruff #126) I think this is the first one I have ever made. Then when it came time to install the coupler, there was no retainer washer in the parts bag. Looking back at my disassembly pictures, there wasn't one installed! Explains the weird flaking on the roller bearing on the input shaft. Pretty simple lathe job to make one and now it is done right!

Making new bushings for the brake actuator. This is kind of a challenge because of how thin the wall of the bushing is. ID is for .75" shaft and the OD is .805" so the wall is only about .025". Chucked some bearing stock in the lathe and turned the OD to size. Then I drilled and bored each bushing individually to control the ID before parting off.

Nice work, but with the weather warming up and longer days you better be spending more time in the shop to have that ready for parades!!!